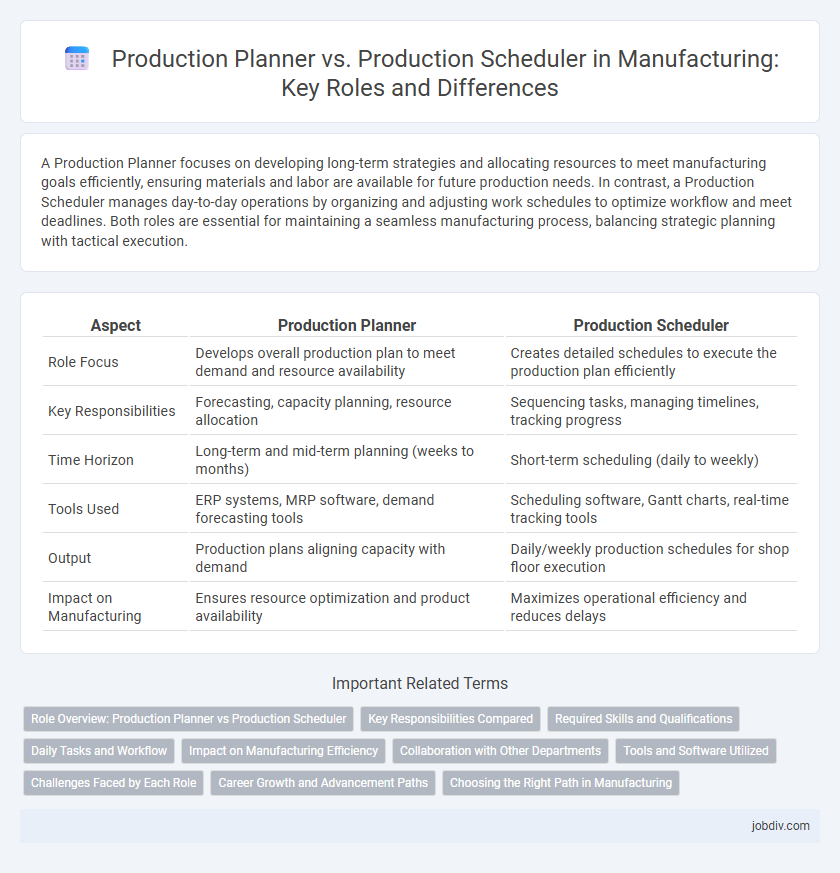

A Production Planner focuses on developing long-term strategies and allocating resources to meet manufacturing goals efficiently, ensuring materials and labor are available for future production needs. In contrast, a Production Scheduler manages day-to-day operations by organizing and adjusting work schedules to optimize workflow and meet deadlines. Both roles are essential for maintaining a seamless manufacturing process, balancing strategic planning with tactical execution.

Table of Comparison

| Aspect | Production Planner | Production Scheduler |

|---|---|---|

| Role Focus | Develops overall production plan to meet demand and resource availability | Creates detailed schedules to execute the production plan efficiently |

| Key Responsibilities | Forecasting, capacity planning, resource allocation | Sequencing tasks, managing timelines, tracking progress |

| Time Horizon | Long-term and mid-term planning (weeks to months) | Short-term scheduling (daily to weekly) |

| Tools Used | ERP systems, MRP software, demand forecasting tools | Scheduling software, Gantt charts, real-time tracking tools |

| Output | Production plans aligning capacity with demand | Daily/weekly production schedules for shop floor execution |

| Impact on Manufacturing | Ensures resource optimization and product availability | Maximizes operational efficiency and reduces delays |

Role Overview: Production Planner vs Production Scheduler

Production Planners develop comprehensive production plans by analyzing demand forecasts, inventory levels, and resource availability to optimize manufacturing efficiency and meet delivery deadlines. Production Schedulers translate these plans into detailed day-to-day schedules, coordinating machine time, labor shifts, and materials to ensure smooth workflow and minimize downtime. The key distinction lies in the planner's strategic role in long-term resource allocation versus the scheduler's tactical focus on immediate task execution within the production cycle.

Key Responsibilities Compared

Production Planners focus on forecasting demand, managing inventory levels, and developing production plans to ensure materials and resources are available for manufacturing processes. Production Schedulers coordinate and sequence the actual production activities on the shop floor, assigning tasks to workers and machines to meet deadlines efficiently. Both roles collaborate to optimize manufacturing workflows, with planners emphasizing strategic resource allocation and schedulers ensuring operational execution.

Required Skills and Qualifications

Production planners require strong analytical skills and proficiency in demand forecasting, inventory management, and resource allocation to develop efficient production plans. Production schedulers must excel in time management, critical thinking, and attention to detail to create detailed schedules that optimize workflow and minimize downtime. Both roles benefit from knowledge of ERP software, lean manufacturing principles, and effective communication for cross-functional collaboration.

Daily Tasks and Workflow

Production planners develop comprehensive production schedules by analyzing demand forecasts, resource availability, and inventory levels to ensure efficient workflow and timely delivery. Production schedulers execute and adjust these schedules on a daily basis, coordinating labor, machinery, and material flow to address immediate operational challenges and minimize downtime. Their combined efforts optimize manufacturing throughput, reduce lead times, and maintain alignment between long-term planning and real-time production activities.

Impact on Manufacturing Efficiency

Production planners strategically allocate resources and forecast materials to optimize workflow, directly reducing downtime and inventory costs. Production schedulers translate these plans into actionable timelines, ensuring machines and labor are utilized efficiently to meet delivery deadlines. Effective collaboration between planners and schedulers enhances manufacturing efficiency by minimizing bottlenecks and balancing production capacity with demand fluctuations.

Collaboration with Other Departments

Production planners coordinate closely with procurement, sales, and engineering departments to ensure materials availability and align production goals with market demand. Production schedulers work hand-in-hand with the shop floor, quality control, and maintenance teams to implement detailed schedules and adapt to real-time operational changes. Effective collaboration between planners and schedulers enhances communication across departments, minimizing delays and optimizing resource utilization in manufacturing processes.

Tools and Software Utilized

Production planners primarily use advanced Enterprise Resource Planning (ERP) systems like SAP and Oracle to manage material requirements planning (MRP), demand forecasting, and resource allocation, ensuring overall production strategy aligns with business objectives. Production schedulers rely on specialized scheduling software such as Preactor, PlanetTogether, or Microsoft Project to optimize production timelines, machine workloads, and workforce shifts for daily and weekly operations. Integration between ERP and scheduling tools facilitates real-time data sharing, enhancing coordination and responsiveness across manufacturing processes.

Challenges Faced by Each Role

Production planners face challenges in demand forecasting accuracy and balancing resource allocation to optimize overall workflow. Production schedulers encounter difficulties managing real-time schedule changes and coordinating machine availability with labor shifts to minimize downtime. Both roles must address supply chain disruptions and maintain communication across departments to ensure seamless production continuity.

Career Growth and Advancement Paths

Production Planners develop strategic plans to optimize manufacturing processes, making them essential for long-term operational efficiency and often advancing into roles like Supply Chain Manager or Operations Director. Production Schedulers focus on detailed day-to-day scheduling, ensuring timely resource allocation and order fulfillment, which can lead to positions such as Scheduling Manager or Production Supervisor. Career growth in both roles leverages expertise in production workflows, with planners typically moving toward higher strategic leadership and schedulers excelling in tactical and team management roles.

Choosing the Right Path in Manufacturing

Production planners focus on strategic forecasting, resource allocation, and setting production goals to optimize manufacturing workflows. Production schedulers translate these plans into actionable timelines, coordinating machine availability, workforce shifts, and material deliveries to ensure on-time production. Selecting the right balance between planning and scheduling improves manufacturing efficiency, reduces lead times, and minimizes costs.

Production Planner vs Production Scheduler Infographic

jobdiv.com

jobdiv.com