Maintenance Technicians perform hands-on repairs and routine inspections to ensure equipment operates efficiently, while Maintenance Engineers design and implement maintenance strategies to improve system reliability and optimize performance. Technicians focus on immediate troubleshooting and hardware maintenance, whereas engineers analyze data and develop long-term solutions for preventive and predictive maintenance. Both roles are essential in minimizing downtime and enhancing overall production efficiency in manufacturing environments.

Table of Comparison

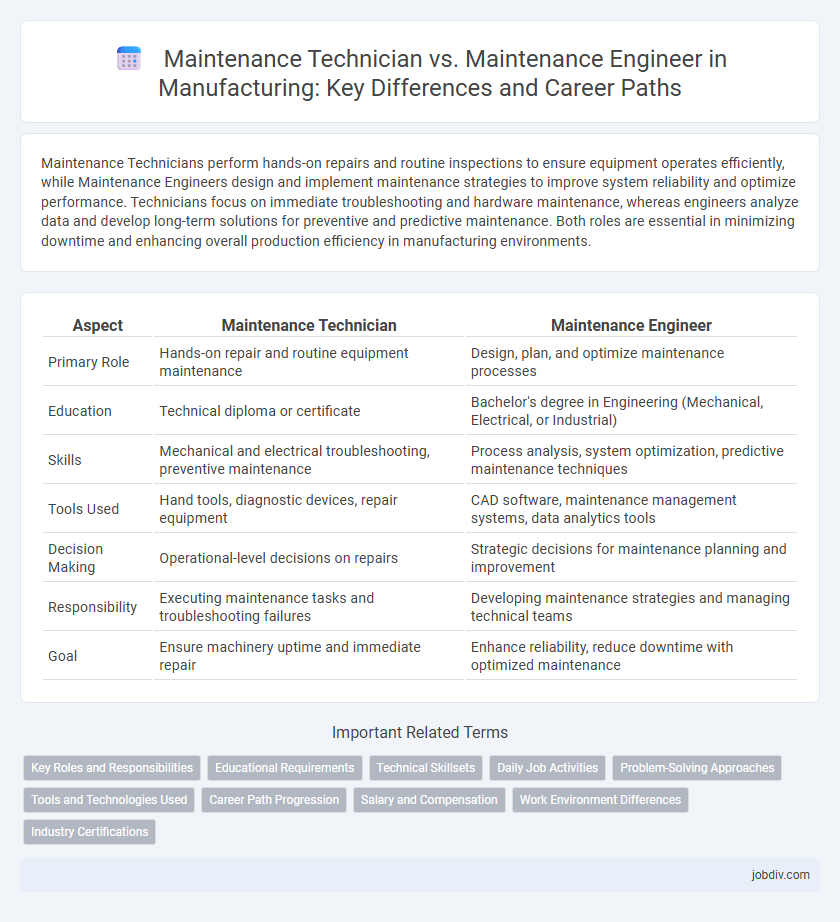

| Aspect | Maintenance Technician | Maintenance Engineer |

|---|---|---|

| Primary Role | Hands-on repair and routine equipment maintenance | Design, plan, and optimize maintenance processes |

| Education | Technical diploma or certificate | Bachelor's degree in Engineering (Mechanical, Electrical, or Industrial) |

| Skills | Mechanical and electrical troubleshooting, preventive maintenance | Process analysis, system optimization, predictive maintenance techniques |

| Tools Used | Hand tools, diagnostic devices, repair equipment | CAD software, maintenance management systems, data analytics tools |

| Decision Making | Operational-level decisions on repairs | Strategic decisions for maintenance planning and improvement |

| Responsibility | Executing maintenance tasks and troubleshooting failures | Developing maintenance strategies and managing technical teams |

| Goal | Ensure machinery uptime and immediate repair | Enhance reliability, reduce downtime with optimized maintenance |

Key Roles and Responsibilities

Maintenance Technicians perform hands-on repairs, routine inspections, and preventive maintenance to ensure machinery operates efficiently. Maintenance Engineers design and implement maintenance strategies, analyze equipment performance data, and lead improvement projects to optimize reliability and reduce downtime. Both roles collaborate closely to maintain operational continuity and enhance manufacturing productivity.

Educational Requirements

Maintenance Technicians typically require a high school diploma or equivalent, often complemented by vocational training or technical certifications in equipment repair and troubleshooting. Maintenance Engineers usually hold a bachelor's degree in mechanical, industrial, or electrical engineering, emphasizing advanced knowledge in system design, predictive maintenance, and process optimization. Engineering education prioritizes analytical skills and theoretical foundations, while technician programs focus more on hands-on skills and practical problem-solving in manufacturing environments.

Technical Skillsets

Maintenance Technicians possess hands-on expertise in diagnosing, repairing, and maintaining machinery using mechanical, electrical, and hydraulic systems knowledge, emphasizing practical troubleshooting and routine servicing. Maintenance Engineers apply advanced engineering principles, including predictive maintenance techniques, systems optimization, and process improvement, leveraging analytical skills and CAD software for designing and upgrading maintenance protocols. Both roles require proficiency in PLC programming and understanding of safety standards, but engineers focus more on strategic planning and innovative solutions, while technicians prioritize operational execution and immediate problem resolution.

Daily Job Activities

Maintenance Technicians perform hands-on troubleshooting, repair, and preventive maintenance of manufacturing equipment to minimize downtime and ensure operational efficiency. Maintenance Engineers analyze machinery performance data, develop maintenance strategies, and design modifications to enhance reliability and optimize production processes. Both roles collaborate closely to address technical issues, with technicians focusing on execution and engineers driving continuous improvement.

Problem-Solving Approaches

Maintenance Technicians address equipment issues through hands-on troubleshooting, relying on practical diagnostics and repair skills to restore functionality quickly. Maintenance Engineers apply analytical problem-solving techniques, using root cause analysis and preventive strategies to optimize system reliability and prevent future failures. The technician's approach is reactive and operational, while the engineer's approach emphasizes proactive design improvements and process optimization.

Tools and Technologies Used

Maintenance Technicians primarily utilize handheld diagnostic tools, multimeters, and basic mechanical instruments to perform routine inspections and repairs on manufacturing equipment. Maintenance Engineers rely on advanced software such as Computerized Maintenance Management Systems (CMMS), predictive analytics platforms, and programmable logic controllers (PLCs) to design maintenance protocols and analyze system performance for optimizing plant operations. Both roles integrate emerging technologies like IoT sensors and augmented reality for real-time monitoring and efficient troubleshooting, but engineers emphasize strategic planning and technology integration while technicians focus on hands-on equipment maintenance.

Career Path Progression

Maintenance Technicians typically start by developing hands-on skills in equipment repair and routine inspections, laying a practical foundation essential for advanced roles. Maintenance Engineers build upon this foundation by applying engineering principles to design, improve, and oversee maintenance systems, often progressing into supervisory or project management positions. Career path progression from technician to engineer involves gaining technical certifications, advanced education, and leadership experience, enabling transition from operational tasks to strategic maintenance planning.

Salary and Compensation

Maintenance engineers typically earn higher salaries than maintenance technicians due to their advanced technical expertise and responsibility for system design improvements, with median annual salaries ranging from $70,000 to $90,000 compared to $45,000 to $60,000 for technicians. Maintenance engineers often receive comprehensive compensation packages, including bonuses and profit-sharing, reflecting their strategic role in reducing downtime and improving operational efficiency. Maintenance technicians generally receive standard wages with potential overtime pay but fewer performance-based incentives.

Work Environment Differences

Maintenance Technicians typically operate on the shop floor, performing hands-on repairs and routine inspections in manufacturing plants, often working with machinery directly. Maintenance Engineers primarily work in office settings or control rooms, focusing on system design, predictive maintenance strategies, and process optimization. The differing work environments highlight the Technician's role in immediate equipment upkeep versus the Engineer's role in long-term maintenance planning and analysis.

Industry Certifications

Maintenance Technicians typically hold industry certifications such as OSHA Safety Certification, Electrical Maintenance Certification, and HVAC Technician Certification, emphasizing hands-on skills and compliance with safety standards. Maintenance Engineers often pursue advanced certifications like Certified Maintenance & Reliability Professional (CMRP) and Six Sigma, highlighting expertise in system optimization, predictive maintenance, and process improvement. Both roles benefit from certification programs that enhance technical knowledge and ensure adherence to industry best practices in manufacturing environments.

Maintenance Technician vs Maintenance Engineer Infographic

jobdiv.com

jobdiv.com