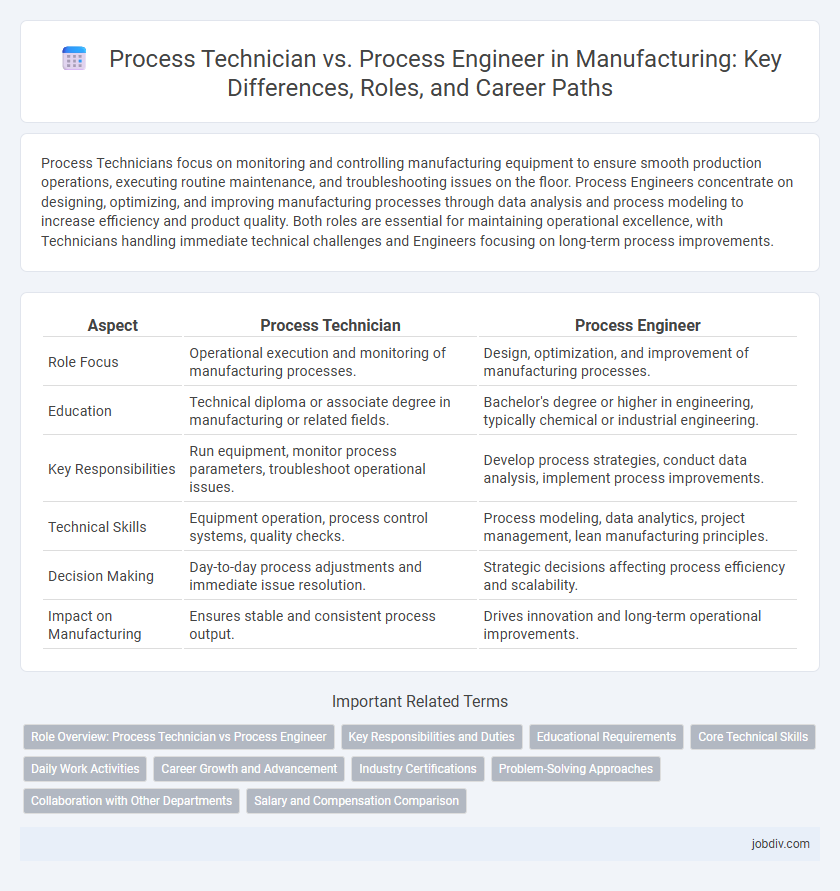

Process Technicians focus on monitoring and controlling manufacturing equipment to ensure smooth production operations, executing routine maintenance, and troubleshooting issues on the floor. Process Engineers concentrate on designing, optimizing, and improving manufacturing processes through data analysis and process modeling to increase efficiency and product quality. Both roles are essential for maintaining operational excellence, with Technicians handling immediate technical challenges and Engineers focusing on long-term process improvements.

Table of Comparison

| Aspect | Process Technician | Process Engineer |

|---|---|---|

| Role Focus | Operational execution and monitoring of manufacturing processes. | Design, optimization, and improvement of manufacturing processes. |

| Education | Technical diploma or associate degree in manufacturing or related fields. | Bachelor's degree or higher in engineering, typically chemical or industrial engineering. |

| Key Responsibilities | Run equipment, monitor process parameters, troubleshoot operational issues. | Develop process strategies, conduct data analysis, implement process improvements. |

| Technical Skills | Equipment operation, process control systems, quality checks. | Process modeling, data analytics, project management, lean manufacturing principles. |

| Decision Making | Day-to-day process adjustments and immediate issue resolution. | Strategic decisions affecting process efficiency and scalability. |

| Impact on Manufacturing | Ensures stable and consistent process output. | Drives innovation and long-term operational improvements. |

Role Overview: Process Technician vs Process Engineer

Process Technicians focus on hands-on operation and monitoring of manufacturing equipment to ensure product quality and process efficiency, often performing routine maintenance and troubleshooting. Process Engineers design, analyze, and optimize manufacturing processes by applying engineering principles and data-driven methods to improve production efficiency, reduce costs, and enhance product consistency. Both roles collaborate closely, with Technicians executing and validating process changes developed by Engineers to maintain smooth manufacturing operations.

Key Responsibilities and Duties

Process Technicians execute and monitor manufacturing processes, ensuring equipment operates within specified parameters and quality standards are met. Process Engineers design, develop, and optimize manufacturing workflows, analyzing data to improve efficiency, reduce costs, and enhance product quality. Both roles collaborate closely to maintain production consistency, troubleshoot issues, and implement continuous improvement initiatives in manufacturing environments.

Educational Requirements

Process Technicians typically require a technical diploma or an associate degree in manufacturing technology or a related field, emphasizing hands-on skills and practical knowledge. Process Engineers often hold a bachelor's degree in chemical, mechanical, or industrial engineering, with advanced understanding of process design, optimization, and analytical tools. Higher education credentials for Process Engineers may include certifications or master's degrees focused on process improvement and engineering principles.

Core Technical Skills

Process Technicians excel in hands-on skills such as equipment calibration, process monitoring, and troubleshooting, ensuring consistent production quality and adherence to standard operating procedures. Process Engineers possess advanced technical expertise in process design, optimization, and analytical techniques, utilizing tools like CAD software and statistical process control to improve manufacturing efficiency. Both roles require proficiency in interpreting process data, but Process Engineers emphasize innovation and scalability, while Process Technicians focus on operational reliability and immediate issue resolution.

Daily Work Activities

Process Technicians handle routine monitoring of manufacturing equipment, conduct quality inspections, and troubleshoot operational issues to ensure smooth production flow. Process Engineers design and optimize production processes, analyze data to improve efficiency, and collaborate with cross-functional teams to implement process improvements. Both roles require a strong understanding of manufacturing systems, but Technicians focus on execution while Engineers emphasize analysis and process enhancement.

Career Growth and Advancement

Process Technicians typically start in hands-on roles supporting manufacturing operations, gaining practical experience with equipment and protocols, which lays a foundation for career progression. Process Engineers engage in designing, analyzing, and optimizing production processes, often requiring advanced technical knowledge and offering faster pathways to leadership and specialized roles. Career advancement for Process Engineers tends to be more rapid due to their critical role in improving efficiency, innovation, and strategic decision-making within manufacturing environments.

Industry Certifications

Process Technicians often hold certifications such as Certified Manufacturing Engineer (CMfgE) and Six Sigma Green Belt, emphasizing practical skills in equipment operation and quality control. Process Engineers typically pursue advanced certifications like Lean Six Sigma Black Belt and Certified Quality Engineer (CQE) to design and optimize manufacturing processes. Industry certifications enhance technical expertise, improve process efficiency, and ensure compliance with quality standards in manufacturing environments.

Problem-Solving Approaches

Process Technicians apply hands-on troubleshooting techniques to identify and resolve equipment malfunctions quickly, using standard operating procedures and immediate corrective actions to minimize downtime. In contrast, Process Engineers engage in analytical problem-solving, utilizing root cause analysis and continuous improvement methodologies like Six Sigma to optimize manufacturing processes and prevent recurring issues. Both roles complement each other by combining practical, on-the-floor problem resolution with strategic process enhancements for efficient production systems.

Collaboration with Other Departments

Process Technicians work closely with production, quality control, and maintenance teams to ensure manufacturing processes run smoothly and meet specifications. Process Engineers collaborate with research and development, supply chain, and safety departments to design and optimize process workflows for efficiency and compliance. Effective communication and teamwork between these roles and departments drive continuous improvement and operational excellence in manufacturing environments.

Salary and Compensation Comparison

Process Technicians typically earn between $45,000 and $65,000 annually, while Process Engineers command higher salaries ranging from $70,000 to $100,000 depending on experience and industry. Compensation packages for Process Engineers often include bonuses and stock options reflecting their strategic role in optimizing manufacturing processes. Benefits for both positions may include health insurance and retirement plans, but Process Engineers generally receive more comprehensive incentives aligned with their advanced responsibilities.

Process Technician vs Process Engineer Infographic

jobdiv.com

jobdiv.com