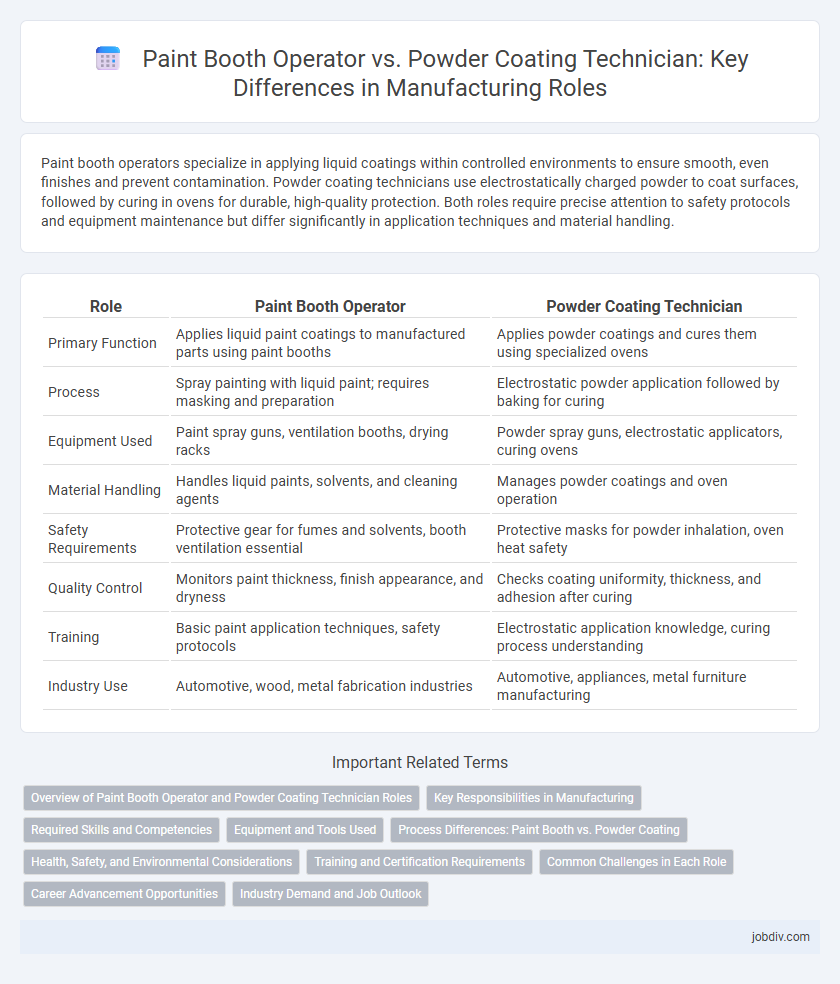

Paint booth operators specialize in applying liquid coatings within controlled environments to ensure smooth, even finishes and prevent contamination. Powder coating technicians use electrostatically charged powder to coat surfaces, followed by curing in ovens for durable, high-quality protection. Both roles require precise attention to safety protocols and equipment maintenance but differ significantly in application techniques and material handling.

Table of Comparison

| Role | Paint Booth Operator | Powder Coating Technician |

|---|---|---|

| Primary Function | Applies liquid paint coatings to manufactured parts using paint booths | Applies powder coatings and cures them using specialized ovens |

| Process | Spray painting with liquid paint; requires masking and preparation | Electrostatic powder application followed by baking for curing |

| Equipment Used | Paint spray guns, ventilation booths, drying racks | Powder spray guns, electrostatic applicators, curing ovens |

| Material Handling | Handles liquid paints, solvents, and cleaning agents | Manages powder coatings and oven operation |

| Safety Requirements | Protective gear for fumes and solvents, booth ventilation essential | Protective masks for powder inhalation, oven heat safety |

| Quality Control | Monitors paint thickness, finish appearance, and dryness | Checks coating uniformity, thickness, and adhesion after curing |

| Training | Basic paint application techniques, safety protocols | Electrostatic application knowledge, curing process understanding |

| Industry Use | Automotive, wood, metal fabrication industries | Automotive, appliances, metal furniture manufacturing |

Overview of Paint Booth Operator and Powder Coating Technician Roles

Paint Booth Operators manage spray painting processes, ensuring even application and compliance with safety and quality standards in manufacturing environments. Powder Coating Technicians specialize in applying powdered paint coatings using electrostatic spray equipment, followed by curing to achieve durable, high-quality finishes. Both roles require knowledge of coating materials, equipment maintenance, and adherence to environmental and workplace safety protocols.

Key Responsibilities in Manufacturing

Paint Booth Operators manage the application of liquid coatings using spray equipment, ensuring even coverage and adherence to quality standards in manufacturing processes. Powder Coating Technicians handle the electrostatic application of powder coatings and oversee curing cycles to achieve durable, high-quality finishes on metal parts. Both roles require strict adherence to safety protocols, equipment maintenance, and collaboration with quality control teams to meet production specifications.

Required Skills and Competencies

Paint Booth Operators require expertise in surface preparation, paint mixing, and spray gun operation, emphasizing attention to detail and color matching skills. Powder Coating Technicians must master chemical knowledge of powder materials, oven curing processes, and equipment maintenance, highlighting precision and safety compliance. Both roles demand strong hand-eye coordination, quality control awareness, and adherence to environmental regulations in manufacturing settings.

Equipment and Tools Used

Paint booth operators typically use spray guns, paint mixers, air compressors, and ventilation systems tailored for liquid paint application, ensuring precise control over paint viscosity and spray patterns. Powder coating technicians rely on electrostatic spray guns, curing ovens, and powder recovery systems designed to apply and cure dry powder coatings uniformly on surfaces. Both roles require specialized protective gear and maintenance of their respective equipment to guarantee high-quality finishes and operational safety.

Process Differences: Paint Booth vs. Powder Coating

Paint booth operators apply liquid coatings using spray guns or airless systems, ensuring precise layer thickness and smooth finishes while managing ventilation and overspray containment. Powder coating technicians utilize electrostatic spray deposition to apply dry powder, followed by curing in an oven, resulting in durable, corrosion-resistant finishes with minimal emissions. The key process differences lie in the medium applied--liquid versus powder--and the curing method, impacting environmental controls and surface preparation techniques.

Health, Safety, and Environmental Considerations

Paint Booth Operators handle liquid coatings requiring ventilation to control inhalation of VOCs and solvent fumes, emphasizing respiratory protection and fire hazard prevention. Powder Coating Technicians work with dry powders, minimizing solvent emissions but necessitating dust control measures to prevent respiratory exposure and explosive dust buildup. Both roles prioritize PPE compliance and waste management protocols to mitigate environmental impact and ensure workplace safety.

Training and Certification Requirements

Paint Booth Operators typically require training in paint mixing, spray techniques, and safety protocols, often obtained through vocational programs or on-the-job experience, with certification like the NACE Coating Inspector Program enhancing job prospects. Powder Coating Technicians need specialized training in surface preparation, powder application, and curing processes, frequently provided by manufacturers or technical schools, with certifications such as the Powder Coating Technician Certification (PCT) validating expertise. Both roles emphasize adherence to environmental and safety regulations, but powder coating demands a higher focus on chemical handling and equipment calibration certifications.

Common Challenges in Each Role

Paint Booth Operators face common challenges such as ensuring uniform paint application, managing overspray control, and maintaining proper ventilation to comply with safety regulations. Powder Coating Technicians frequently encounter difficulties with achieving consistent coating thickness, controlling curing oven temperatures, and preventing contamination that affects finish quality. Both roles require meticulous attention to detail and adherence to environmental standards to produce high-quality surface finishes in manufacturing settings.

Career Advancement Opportunities

Paint Booth Operators typically gain experience in surface preparation and liquid paint application, which can lead to supervisory roles or quality control positions within automotive and industrial manufacturing sectors. Powder Coating Technicians develop expertise in electrostatic coating techniques and curing processes, opening pathways to advanced roles in process optimization, equipment maintenance, or technical training. Both career tracks offer progression into specialized functions such as paint process engineering or production management, driven by skill enhancement and certifications in coating technologies.

Industry Demand and Job Outlook

Paint booth operators and powder coating technicians both play critical roles in manufacturing, with powder coating technicians currently experiencing higher industry demand due to the growing preference for durable, eco-friendly finishes in automotive and aerospace sectors. Employment projections indicate a faster job outlook growth for powder coating technicians, fueled by advancements in powder application technologies and increasing regulatory compliance requiring safer coating methods. Paint booth operators remain essential, especially in traditional manufacturing settings, but may face slower growth as more facilities transition to powder coating systems.

Paint Booth Operator vs Powder Coating Technician Infographic

jobdiv.com

jobdiv.com