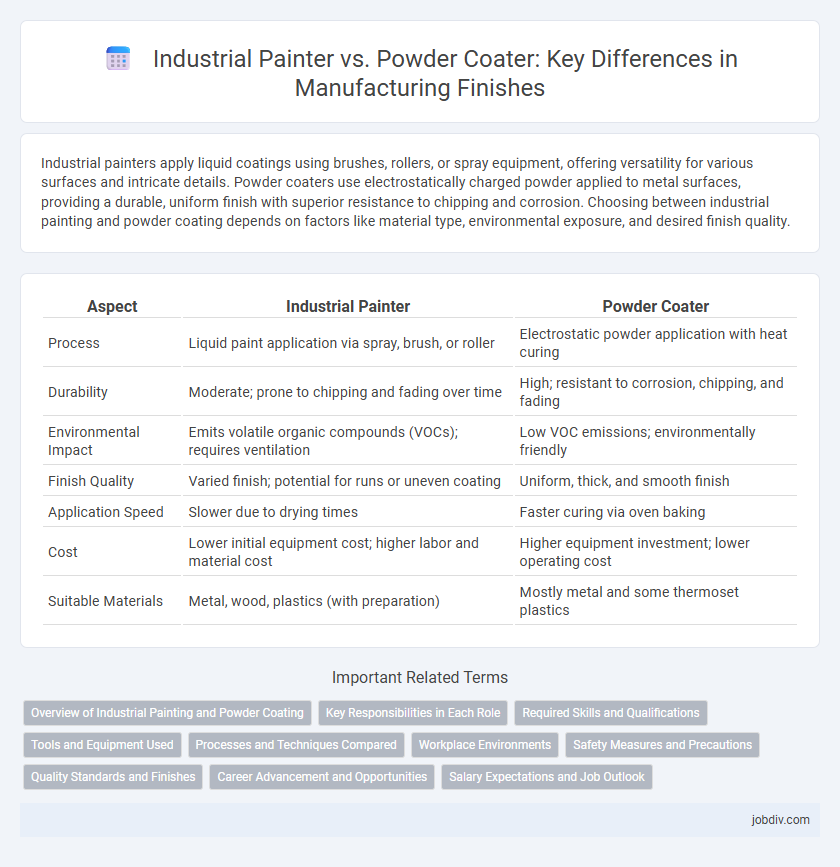

Industrial painters apply liquid coatings using brushes, rollers, or spray equipment, offering versatility for various surfaces and intricate details. Powder coaters use electrostatically charged powder applied to metal surfaces, providing a durable, uniform finish with superior resistance to chipping and corrosion. Choosing between industrial painting and powder coating depends on factors like material type, environmental exposure, and desired finish quality.

Table of Comparison

| Aspect | Industrial Painter | Powder Coater |

|---|---|---|

| Process | Liquid paint application via spray, brush, or roller | Electrostatic powder application with heat curing |

| Durability | Moderate; prone to chipping and fading over time | High; resistant to corrosion, chipping, and fading |

| Environmental Impact | Emits volatile organic compounds (VOCs); requires ventilation | Low VOC emissions; environmentally friendly |

| Finish Quality | Varied finish; potential for runs or uneven coating | Uniform, thick, and smooth finish |

| Application Speed | Slower due to drying times | Faster curing via oven baking |

| Cost | Lower initial equipment cost; higher labor and material cost | Higher equipment investment; lower operating cost |

| Suitable Materials | Metal, wood, plastics (with preparation) | Mostly metal and some thermoset plastics |

Overview of Industrial Painting and Powder Coating

Industrial painting involves applying liquid paints or coatings to surfaces using spray, brush, or roller methods to protect and enhance metal, wood, or concrete structures. Powder coating uses electrostatically charged powders that are baked onto surfaces, creating a durable, corrosion-resistant finish ideal for automotive, machinery, and architectural components. Both methods improve product longevity and aesthetic appeal, but powder coating typically offers superior resistance to wear, chemicals, and UV exposure.

Key Responsibilities in Each Role

Industrial painters apply liquid coatings such as paints, primers, and sealants to metal surfaces to protect against corrosion and enhance appearance, often using spray guns or brushes in manufacturing environments. Powder coaters prepare surfaces through cleaning and sanding before applying a dry powder electrostatically, which is then cured under heat to create a durable, uniform finish commonly used for automotive parts and appliances. Both roles require expertise in surface preparation, safety protocols, and quality control, but industrial painters focus on liquid applications while powder coaters specialize in electrostatic powder techniques.

Required Skills and Qualifications

Industrial painters require proficiency in surface preparation, knowledge of various paint types, and expertise in applying coatings using spray guns or brushes, along with safety compliance and the ability to work in confined spaces. Powder coaters must have skills in electrostatic application, understanding of curing processes, and competence in operating powder coating equipment, as well as familiarity with quality control techniques and environmental regulations. Both roles demand attention to detail, manual dexterity, and adherence to industry safety standards to ensure durable and high-quality finishes.

Tools and Equipment Used

Industrial painters primarily use spray guns, air compressors, brushes, and rollers designed for applying liquid coatings such as enamel or epoxy paints to various surfaces in manufacturing settings. Powder coaters rely on electrostatic spray guns, curing ovens, and fluidized beds to apply and heat-cure powdered paint that provides a durable, high-quality finish. Both processes require specialized ventilation systems and safety gear to protect workers from hazardous fumes and particles during coating application.

Processes and Techniques Compared

Industrial painters apply liquid coatings using spray guns or brushes, requiring multiple layers and drying times to achieve durability and finish quality. Powder coating involves electrostatically applying dry powder, which is then cured under heat to form a strong, uniform, and corrosion-resistant layer. While industrial painting allows for more color variation and touch-ups, powder coating offers superior adhesion and environmental benefits due to its solvent-free process.

Workplace Environments

Industrial painters typically work in well-ventilated spray booths or open areas with protective gear due to exposure to liquid solvents and volatile organic compounds. Powder coaters operate in controlled environments with specialized ovens and electrostatic spray equipment, minimizing airborne contaminants and ensuring consistent curing conditions. Both roles require strict adherence to safety protocols, but powder coating environments emphasize temperature control and particulate management, while industrial painting focuses more on ventilation and chemical handling.

Safety Measures and Precautions

Industrial painters handle liquid coatings requiring ventilation systems and protective gear like respirators and gloves to prevent inhalation of fumes and skin contact with hazardous chemicals. Powder coaters use electrostatic spray guns and cure coatings with heat; they must ensure proper grounding and wear anti-static clothing to avoid sparks and dust inhalation. Both processes demand rigorous training and adherence to OSHA safety standards to minimize workplace accidents and health risks.

Quality Standards and Finishes

Industrial painters typically apply liquid coatings that offer flexibility in color options and can achieve smooth, glossy finishes, meeting stringent quality standards for corrosion resistance and durability. Powder coaters utilize dry powder applied electrostatically and cured under heat, resulting in thicker, more uniform coatings that provide superior resistance to chipping, scratching, and fading, essential for high-performance industrial applications. Both processes adhere to industry standards such as ISO 12944 for corrosion protection, with powder coating often preferred for its environmental benefits and longer-lasting finish consistency.

Career Advancement and Opportunities

Industrial painters benefit from diverse opportunities in sectors like automotive, construction, and shipbuilding, with career advancement often tied to mastering various coatings and safety protocols. Powder coaters possess specialized skills in applying durable, electrostatically charged powder finishes, in demand for high-tech manufacturing and consumer goods industries, leading to roles in quality control and process optimization. Both careers offer pathways to supervisory positions and technical expertise, but powder coating generally provides greater potential in innovative and environmentally friendly manufacturing processes.

Salary Expectations and Job Outlook

Industrial painters typically earn between $35,000 and $55,000 annually, with salary variations depending on experience and geographic location, while powder coaters often see salaries ranging from $30,000 to $50,000. The job outlook for both roles remains steady, driven by ongoing demand in automotive, aerospace, and construction industries, with industrial painters experiencing slightly faster growth due to specialized coating techniques. Skill upgrades and certification can enhance earning potential and job security for professionals in either occupation.

Industrial Painter vs Powder Coater Infographic

jobdiv.com

jobdiv.com