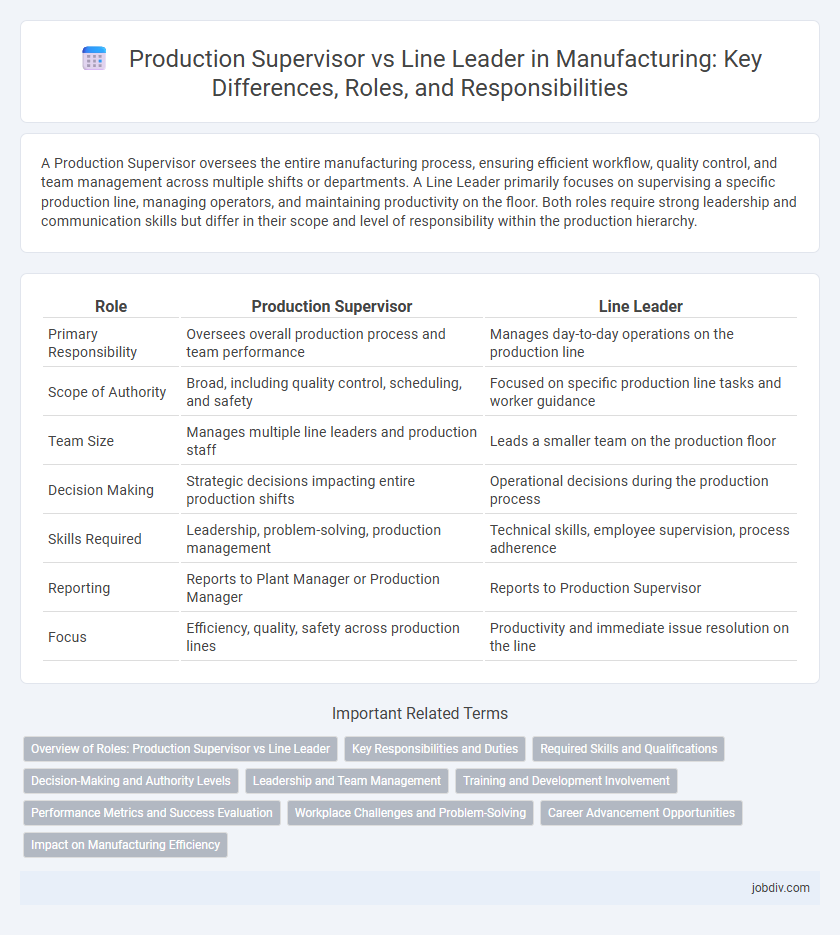

A Production Supervisor oversees the entire manufacturing process, ensuring efficient workflow, quality control, and team management across multiple shifts or departments. A Line Leader primarily focuses on supervising a specific production line, managing operators, and maintaining productivity on the floor. Both roles require strong leadership and communication skills but differ in their scope and level of responsibility within the production hierarchy.

Table of Comparison

| Role | Production Supervisor | Line Leader |

|---|---|---|

| Primary Responsibility | Oversees overall production process and team performance | Manages day-to-day operations on the production line |

| Scope of Authority | Broad, including quality control, scheduling, and safety | Focused on specific production line tasks and worker guidance |

| Team Size | Manages multiple line leaders and production staff | Leads a smaller team on the production floor |

| Decision Making | Strategic decisions impacting entire production shifts | Operational decisions during the production process |

| Skills Required | Leadership, problem-solving, production management | Technical skills, employee supervision, process adherence |

| Reporting | Reports to Plant Manager or Production Manager | Reports to Production Supervisor |

| Focus | Efficiency, quality, safety across production lines | Productivity and immediate issue resolution on the line |

Overview of Roles: Production Supervisor vs Line Leader

A Production Supervisor manages overall manufacturing operations, including workforce coordination, quality control, and meeting production targets, ensuring seamless workflow across multiple production lines. A Line Leader focuses on overseeing specific assembly line tasks, directly guiding operators and maintaining equipment efficiency to achieve daily output goals. Both roles are essential for operational success but differ in scope, with supervisors handling broader managerial responsibilities and line leaders concentrating on frontline execution.

Key Responsibilities and Duties

A Production Supervisor oversees the entire manufacturing process, managing schedules, coordinating teams, and ensuring quality standards meet company requirements. A Line Leader directs specific assembly line operations, focusing on workflow efficiency, monitoring worker performance, and addressing immediate production issues. Both roles require strong leadership and communication skills, but the Production Supervisor handles broader operational planning, while the Line Leader concentrates on day-to-day line management.

Required Skills and Qualifications

Production Supervisors require strong leadership, project management, and communication skills, alongside proficiency in quality control and safety compliance standards. Line Leaders must demonstrate hands-on expertise in machine operation, team coordination, and problem-solving on the production floor, often requiring technical certifications or industry-specific training. Both roles benefit from experience in Lean manufacturing principles and a solid understanding of workflow optimization to enhance efficiency.

Decision-Making and Authority Levels

Production supervisors oversee multiple production lines, making strategic decisions on workflow optimization, resource allocation, and quality control while holding higher authority to enforce policies and resolve conflicts. Line leaders manage a specific production line, focusing on immediate operational decisions, guiding team tasks, and maintaining daily production targets under the supervisor's direction. Authority levels differ as production supervisors have broader decision-making power across shifts, whereas line leaders execute decisions within their assigned line.

Leadership and Team Management

Production Supervisors oversee entire manufacturing processes, ensuring efficient workflow and quality control while managing multiple teams and coordinating resources. Line Leaders focus on leading specific workstations or assembly lines, directly guiding operators to meet daily production targets and maintain safety standards. Strong leadership in both roles drives team productivity and fosters a collaborative work environment that supports continuous improvement.

Training and Development Involvement

Production Supervisors typically oversee broader training programs, ensuring alignment with company standards and safety regulations, while Line Leaders focus on hands-on skill development and immediate problem-solving with their team. Supervisors coordinate cross-functional training initiatives and assess workforce competency, enhancing overall production efficiency. Line Leaders provide continuous on-the-floor guidance and real-time coaching, directly influencing skill enhancement and employee engagement during shifts.

Performance Metrics and Success Evaluation

Production Supervisors are evaluated based on overall manufacturing efficiency, quality control, and labor cost management, using key performance indicators (KPIs) such as throughput rates, defect rates, and adherence to production schedules. Line Leaders focus on real-time process adherence, employee productivity, and immediate issue resolution, with success measured through metrics like cycle time, downtime reduction, and first-pass yield. Both roles require analysis of quantitative data to drive continuous improvement, yet Production Supervisors oversee broader operational goals while Line Leaders manage day-to-day production line performance.

Workplace Challenges and Problem-Solving

Production Supervisors oversee overall manufacturing processes, managing resource allocation and ensuring compliance with quality standards, which demands advanced problem-solving skills to address complex workflow disruptions and equipment failures. Line Leaders directly coordinate frontline workers, tackling personnel conflicts and maintaining productivity, often resolving real-time issues like bottlenecks and safety hazards on the production floor. Both roles require effective communication and leadership but differ in scope, with Production Supervisors focusing on strategic problem-solving and Line Leaders on tactical, immediate challenges.

Career Advancement Opportunities

Production supervisors typically oversee entire shifts or departments, managing resources and ensuring quality standards, which positions them for advancement into higher management roles like plant manager or operations director. Line leaders focus on specific production lines, directly coordinating frontline workers and addressing operational issues, providing foundational experience critical for moving into supervisory positions. Career advancement opportunities for production supervisors usually involve broader managerial responsibilities and strategic decision-making, while line leaders progress by developing technical skills and leadership abilities essential for supervisory roles.

Impact on Manufacturing Efficiency

Production Supervisors oversee entire manufacturing processes, ensuring optimal workflow, resource allocation, and adherence to quality standards, which significantly enhances overall efficiency. Line Leaders focus on direct management of production line workers, addressing immediate operational issues and maintaining pace to reduce downtime and defects. The combined effectiveness of Production Supervisors and Line Leaders directly influences manufacturing throughput, product quality, and cost reduction.

Production Supervisor vs Line Leader Infographic

jobdiv.com

jobdiv.com