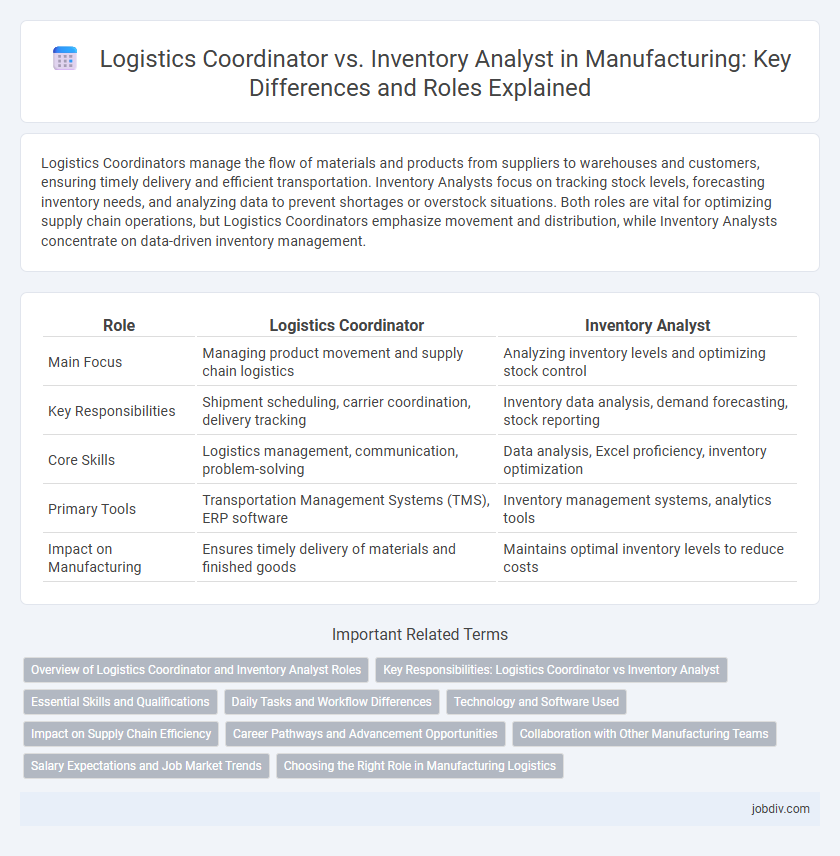

Logistics Coordinators manage the flow of materials and products from suppliers to warehouses and customers, ensuring timely delivery and efficient transportation. Inventory Analysts focus on tracking stock levels, forecasting inventory needs, and analyzing data to prevent shortages or overstock situations. Both roles are vital for optimizing supply chain operations, but Logistics Coordinators emphasize movement and distribution, while Inventory Analysts concentrate on data-driven inventory management.

Table of Comparison

| Role | Logistics Coordinator | Inventory Analyst |

|---|---|---|

| Main Focus | Managing product movement and supply chain logistics | Analyzing inventory levels and optimizing stock control |

| Key Responsibilities | Shipment scheduling, carrier coordination, delivery tracking | Inventory data analysis, demand forecasting, stock reporting |

| Core Skills | Logistics management, communication, problem-solving | Data analysis, Excel proficiency, inventory optimization |

| Primary Tools | Transportation Management Systems (TMS), ERP software | Inventory management systems, analytics tools |

| Impact on Manufacturing | Ensures timely delivery of materials and finished goods | Maintains optimal inventory levels to reduce costs |

Overview of Logistics Coordinator and Inventory Analyst Roles

A Logistics Coordinator manages the transportation and distribution of materials, ensuring timely delivery and optimizing supply chain efficiency within manufacturing operations. An Inventory Analyst specializes in monitoring stock levels, analyzing inventory data to forecast demand, and preventing shortages or excesses that impact production flow. Both roles are essential for maintaining seamless operations, with Logistics Coordinators focusing on movement and coordination, while Inventory Analysts concentrate on data-driven inventory control.

Key Responsibilities: Logistics Coordinator vs Inventory Analyst

Logistics Coordinators manage supply chain operations by overseeing transportation schedules, coordinating shipments, and ensuring timely delivery to optimize production flow. Inventory Analysts analyze stock levels, forecast demand, and implement inventory control strategies to minimize shortages and excesses. Both roles are critical in manufacturing for maintaining efficient inventory turnover and supporting seamless logistical execution.

Essential Skills and Qualifications

Logistics Coordinators require strong organizational skills, proficiency in supply chain management software, and effective communication abilities to manage transportation schedules and vendor relationships efficiently. Inventory Analysts must excel in data analysis, inventory control systems, and forecasting techniques to optimize stock levels and minimize carrying costs. Both roles benefit from problem-solving skills, attention to detail, and knowledge of logistics and inventory management principles within the manufacturing sector.

Daily Tasks and Workflow Differences

Logistics Coordinators manage the transportation, scheduling, and distribution of materials, ensuring timely delivery within manufacturing operations. Inventory Analysts focus on tracking stock levels, analyzing inventory data to forecast demand, and minimizing holding costs. While Logistics Coordinators prioritize external supply chain coordination, Inventory Analysts concentrate on internal inventory accuracy and efficiency.

Technology and Software Used

Logistics Coordinators heavily utilize transportation management systems (TMS) and warehouse management software (WMS) like SAP EWM and Oracle SCM Cloud to optimize shipment scheduling and track deliveries in real-time. Inventory Analysts rely on advanced inventory management tools such as NetSuite ERP and Microsoft Dynamics 365 to analyze stock levels, forecast demand, and automate replenishment processes. Both roles benefit from integration platforms like Tableau and Power BI for data visualization and reporting, enhancing decision-making accuracy in manufacturing supply chains.

Impact on Supply Chain Efficiency

Logistics Coordinators optimize transportation routes and manage shipment schedules to reduce delivery times and cut costs, directly enhancing supply chain efficiency. Inventory Analysts forecast demand and monitor stock levels to minimize excess inventory and prevent stockouts, ensuring smooth production flow. Both roles collaborate to synchronize material availability with logistics operations, driving a responsive and cost-effective supply chain.

Career Pathways and Advancement Opportunities

Logistics Coordinators typically advance by gaining expertise in supply chain management and operational efficiency, moving into roles such as Logistics Manager or Supply Chain Director. Inventory Analysts often progress by developing analytical skills and mastering demand forecasting, leading to positions like Inventory Manager or Operations Analyst. Both career paths offer opportunities to specialize in data analytics, process optimization, and strategic planning within the manufacturing industry.

Collaboration with Other Manufacturing Teams

Logistics Coordinators work closely with production and procurement teams to ensure timely delivery of materials, optimizing the supply chain and reducing downtime. Inventory Analysts collaborate with quality control and warehouse teams to maintain accurate stock levels and forecast demand, preventing production delays and excess inventory. Both roles are essential for synchronizing operations and enhancing overall manufacturing efficiency.

Salary Expectations and Job Market Trends

Logistics Coordinators in manufacturing typically earn between $45,000 and $65,000 annually, reflecting strong demand for supply chain organization and distribution expertise. Inventory Analysts command salaries ranging from $50,000 to $70,000 due to their critical role in managing stock levels, reducing waste, and optimizing procurement processes. The job market shows a growing need for Inventory Analysts as companies prioritize data-driven inventory management, while Logistics Coordinators remain essential for ensuring timely delivery and operational efficiency.

Choosing the Right Role in Manufacturing Logistics

Logistics Coordinators in manufacturing manage the timely movement of materials and coordinate with suppliers and transportation providers to ensure production schedules are met. Inventory Analysts focus on data analysis to optimize stock levels, reduce holding costs, and prevent production delays by forecasting demand accurately. Selecting the right role depends on whether the priority is operational coordination or data-driven inventory optimization.

Logistics Coordinator vs Inventory Analyst Infographic

jobdiv.com

jobdiv.com