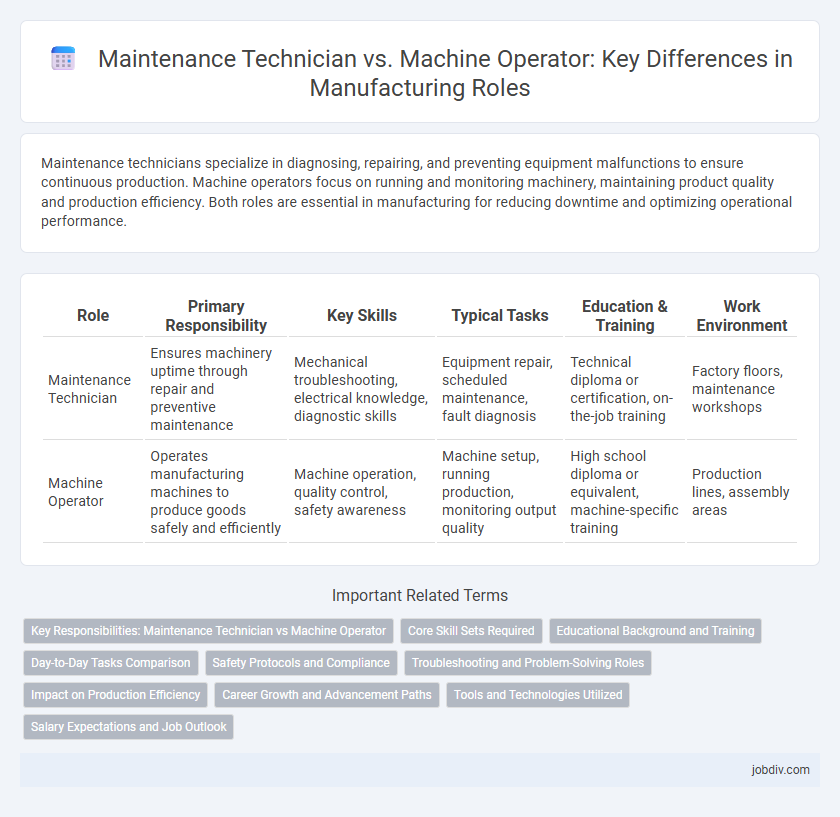

Maintenance technicians specialize in diagnosing, repairing, and preventing equipment malfunctions to ensure continuous production. Machine operators focus on running and monitoring machinery, maintaining product quality and production efficiency. Both roles are essential in manufacturing for reducing downtime and optimizing operational performance.

Table of Comparison

| Role | Primary Responsibility | Key Skills | Typical Tasks | Education & Training | Work Environment |

|---|---|---|---|---|---|

| Maintenance Technician | Ensures machinery uptime through repair and preventive maintenance | Mechanical troubleshooting, electrical knowledge, diagnostic skills | Equipment repair, scheduled maintenance, fault diagnosis | Technical diploma or certification, on-the-job training | Factory floors, maintenance workshops |

| Machine Operator | Operates manufacturing machines to produce goods safely and efficiently | Machine operation, quality control, safety awareness | Machine setup, running production, monitoring output quality | High school diploma or equivalent, machine-specific training | Production lines, assembly areas |

Key Responsibilities: Maintenance Technician vs Machine Operator

Maintenance Technicians specialize in troubleshooting, repairing, and performing preventive maintenance on manufacturing equipment to minimize downtime and ensure operational efficiency. Machine Operators focus on setting up, operating, and monitoring machinery to produce parts according to specifications while maintaining quality and safety standards. Both roles require technical knowledge, but Maintenance Technicians emphasize mechanical and electrical repairs, whereas Machine Operators prioritize machine operation and production flow.

Core Skill Sets Required

Maintenance Technicians require expert knowledge in troubleshooting, mechanical repair, and preventive maintenance to ensure machinery operates efficiently and minimize downtime. Machine Operators focus on skills such as machine setup, precision control, and monitoring production processes to maintain product quality and workflow consistency. Both roles demand strong problem-solving abilities, attention to detail, and adherence to safety protocols in manufacturing environments.

Educational Background and Training

Maintenance Technicians typically possess a technical diploma or an associate degree in industrial maintenance, electrical systems, or mechanical engineering, complemented by specialized certifications such as PLC programming or hydraulics training. Machine Operators often acquire skills through high school education combined with on-the-job training focused on equipment handling, operation procedures, and safety protocols. Continuous professional development for Maintenance Technicians emphasizes advanced troubleshooting and preventive maintenance, whereas Machine Operators concentrate on machine-specific operation efficiency and quality control.

Day-to-Day Tasks Comparison

Maintenance Technicians perform preventive and corrective maintenance on machinery, troubleshoot mechanical failures, and ensure equipment operates at peak efficiency. Machine Operators primarily execute production tasks by running and monitoring machines, making minor adjustments, and inspecting output quality. While Maintenance Technicians focus on equipment reliability and repair, Machine Operators concentrate on maintaining consistent production flow and product standards.

Safety Protocols and Compliance

Maintenance Technicians perform regular equipment inspections and implement preventive measures to ensure machinery operates within safety standards, reducing downtime and hazards. Machine Operators follow strict operational guidelines and safety protocols to handle machinery properly, aiming to prevent accidents and maintain compliance with regulatory requirements. Both roles require adherence to OSHA safety standards and ongoing training to uphold workplace safety and ensure regulatory compliance in manufacturing environments.

Troubleshooting and Problem-Solving Roles

Maintenance technicians specialize in diagnosing and repairing mechanical, electrical, and hydraulic equipment failures to ensure minimal downtime in manufacturing operations. Machine operators primarily focus on running and monitoring machinery, identifying operational issues, and performing basic troubleshooting to maintain consistent production quality. Advanced problem-solving tasks and complex repairs typically fall under the maintenance technician's responsibilities, requiring deeper technical expertise and diagnostic skills.

Impact on Production Efficiency

Maintenance Technicians play a critical role in maximizing production efficiency by rapidly diagnosing and repairing equipment faults, minimizing downtime, and ensuring machines operate at optimal performance. Machine Operators directly influence efficiency through precise control and adjustment of machinery, maintaining consistent output quality and reducing waste. The combined expertise of Maintenance Technicians and Machine Operators enhances overall manufacturing productivity by preventing disruptions and sustaining steady production flow.

Career Growth and Advancement Paths

Maintenance Technicians typically experience faster career growth due to specialized skills in troubleshooting, repairing, and preventive maintenance of manufacturing equipment, leading to roles such as Maintenance Supervisor or Engineering Technician. Machine Operators often start with hands-on production tasks, with advancement opportunities including Lead Operator or Production Supervisor, but may require additional technical training to transition into maintenance or engineering roles. Both paths benefit from certifications like OSHA and Six Sigma, enhancing promotion prospects within manufacturing facilities.

Tools and Technologies Utilized

Maintenance Technicians leverage diagnostic tools, programmable logic controllers (PLCs), and computerized maintenance management systems (CMMS) to troubleshoot, repair, and optimize manufacturing equipment efficiently. Machine Operators primarily use control panels, automated machinery interfaces, and precision measuring instruments to operate and monitor production lines ensuring consistent output quality. The integration of IoT sensors and real-time data analytics increasingly enhances both roles by enabling predictive maintenance and improving process automation in manufacturing environments.

Salary Expectations and Job Outlook

Maintenance Technicians in manufacturing typically earn higher salaries than Machine Operators due to their specialized skills in repairing and maintaining complex equipment, with median annual wages reaching $58,000 compared to $37,000 for operators. The job outlook for Maintenance Technicians is projected to grow 8% over the next decade, driven by increasing automation and the need for skilled technical support, while Machine Operator roles are expected to decline by 5% due to automation and outsourcing. Employers prioritize experienced Maintenance Technicians for their ability to minimize downtime, which directly impacts production efficiency and operational costs.

Maintenance Technician vs Machine Operator Infographic

jobdiv.com

jobdiv.com