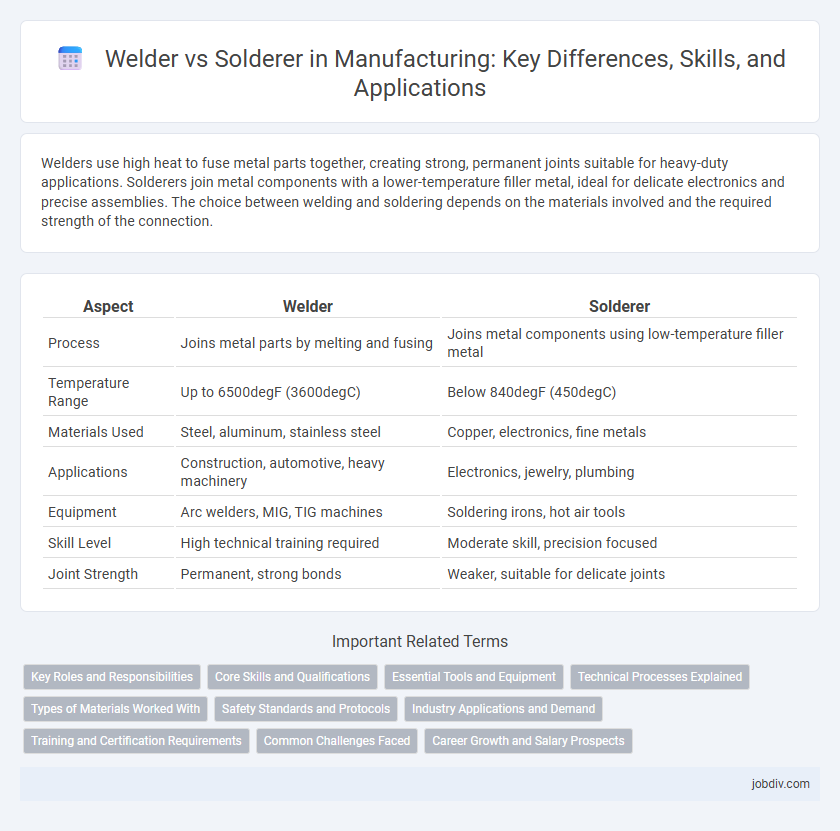

Welders use high heat to fuse metal parts together, creating strong, permanent joints suitable for heavy-duty applications. Solderers join metal components with a lower-temperature filler metal, ideal for delicate electronics and precise assemblies. The choice between welding and soldering depends on the materials involved and the required strength of the connection.

Table of Comparison

| Aspect | Welder | Solderer |

|---|---|---|

| Process | Joins metal parts by melting and fusing | Joins metal components using low-temperature filler metal |

| Temperature Range | Up to 6500degF (3600degC) | Below 840degF (450degC) |

| Materials Used | Steel, aluminum, stainless steel | Copper, electronics, fine metals |

| Applications | Construction, automotive, heavy machinery | Electronics, jewelry, plumbing |

| Equipment | Arc welders, MIG, TIG machines | Soldering irons, hot air tools |

| Skill Level | High technical training required | Moderate skill, precision focused |

| Joint Strength | Permanent, strong bonds | Weaker, suitable for delicate joints |

Key Roles and Responsibilities

Welders join metal parts by applying high heat to create strong, permanent bonds essential for structural integrity in manufacturing. Solderers, on the other hand, use a lower-temperature process to melt filler metal that connects electronic components or delicate assemblies without damaging them. Both roles require precision, but welders focus on heavy-duty fabrications while solderers specialize in fine, detailed work on circuits and small parts.

Core Skills and Qualifications

Welders require expertise in metal fusion techniques such as MIG, TIG, and arc welding, alongside knowledge of metallurgy and blueprints interpretation to ensure precise joins. Solderers specialize in using low-melting-point alloys to join electronic components, demanding fine motor skills, attention to circuit board layouts, and proficiency with soldering irons and desoldering tools. Both roles necessitate strong safety awareness and quality control, but welders emphasize structural integrity while solderers focus on electrical conductivity and delicate assembly.

Essential Tools and Equipment

Welders require essential tools such as welding machines, electrodes, protective helmets, gloves, and welding clamps to join metals through high heat. Solderers use soldering irons, solder wire, flux, tweezers, and magnifying tools to create low-temperature metal connections, primarily for electronics and small components. Both professions depend on specialized safety gear and precise equipment to ensure strong bonds and prevent damage to materials.

Technical Processes Explained

Welding involves joining metals by melting the base materials and adding a filler metal to form a strong joint, typically using techniques like MIG, TIG, or arc welding. Soldering joins metals without melting the base, using a lower-temperature filler metal with a melting point below 450degC, ideal for delicate electrical connections. Welding achieves structural strength for heavy-duty applications, whereas soldering is suited for precision work requiring minimal heat and electrical conductivity.

Types of Materials Worked With

Welders primarily work with metals such as steel, aluminum, and stainless steel, using high heat to fuse materials into a strong joint. Solderers handle metals and electronic components, focusing on softer metals like copper, gold, and silver, using a lower-temperature filler metal to create precise, conductive bonds. Material compatibility dictates the choice between welding or soldering in manufacturing processes.

Safety Standards and Protocols

Welders and solderers follow distinct safety standards due to varying risks in manufacturing environments, with welders adhering to OSHA welding safety regulations such as proper ventilation, fire-resistant clothing, and eye protection to prevent burns and fume inhalation. Solderers focus on protocols to minimize exposure to hazardous fumes from lead-based solders, often using fume extractors and wearing protective gloves to avoid chemical contact and burns. Both professionals require training in handling equipment safely and emergency response to maintain compliance with industry safety standards.

Industry Applications and Demand

Welders are essential in heavy industries such as construction, automotive, aerospace, and shipbuilding where strong, permanent metal joints are required to ensure structural integrity. Solderers are in high demand in electronics manufacturing, plumbing, and delicate metalwork, where precision and lower heat application are critical for assembling circuit boards and small components. Industry trends show increased demand for welders due to infrastructure expansion, while solderers remain vital in consumer electronics and renewable energy sectors.

Training and Certification Requirements

Welders typically require formal training programs that cover various welding techniques such as MIG, TIG, and arc welding, often followed by certification through organizations like the American Welding Society (AWS). Solderers, on the other hand, undergo specialized training focused on precision and electronics applications, with certifications available from bodies such as the IPC-A-610 for electronics assembly. Both roles demand rigorous skill assessments and practical tests to ensure safety, quality, and compliance with industry standards.

Common Challenges Faced

Welders and solderers often encounter challenges such as managing heat distortion and ensuring strong joint integrity under varying material conditions. Both professions must address issues like insufficient bonding caused by improper technique or contaminated surfaces, impacting structural reliability. The need for precise temperature control and adherence to safety standards remains critical to prevent defects and workplace hazards.

Career Growth and Salary Prospects

Welders typically experience stronger career growth due to higher demand in heavy industries like construction, automotive, and aerospace, with median salaries ranging from $42,000 to $60,000 annually. Solderers often work in electronics and small-scale manufacturing, where salary prospects average between $30,000 and $45,000 but can increase with specialization in microelectronics. Both careers offer advancement through certifications and technical training, yet welders generally access higher-paying supervisory and inspection roles.

Welder vs Solderer Infographic

jobdiv.com

jobdiv.com