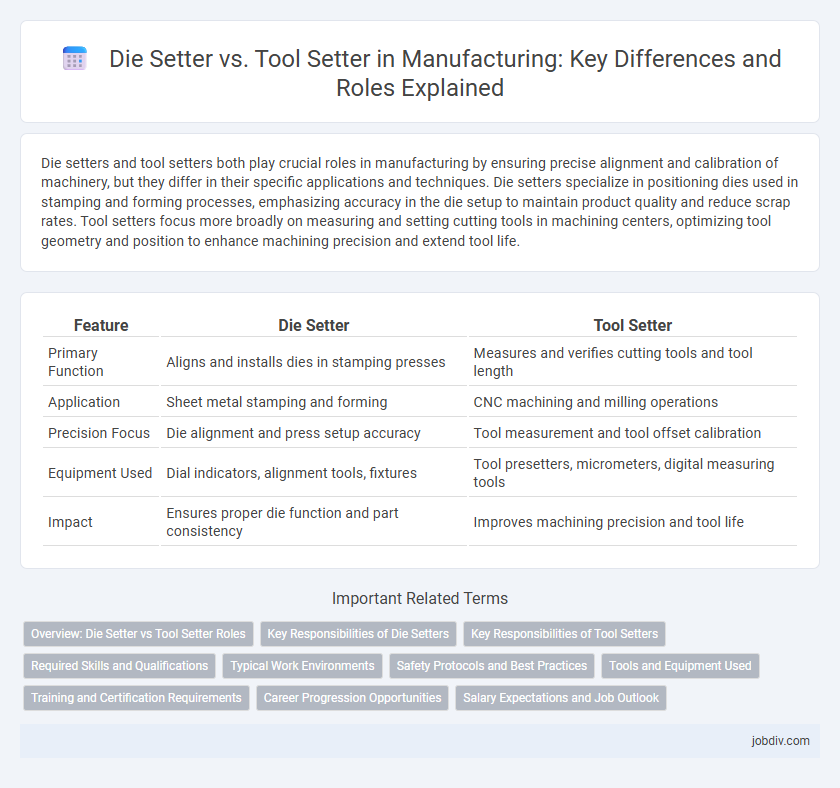

Die setters and tool setters both play crucial roles in manufacturing by ensuring precise alignment and calibration of machinery, but they differ in their specific applications and techniques. Die setters specialize in positioning dies used in stamping and forming processes, emphasizing accuracy in the die setup to maintain product quality and reduce scrap rates. Tool setters focus more broadly on measuring and setting cutting tools in machining centers, optimizing tool geometry and position to enhance machining precision and extend tool life.

Table of Comparison

| Feature | Die Setter | Tool Setter |

|---|---|---|

| Primary Function | Aligns and installs dies in stamping presses | Measures and verifies cutting tools and tool length |

| Application | Sheet metal stamping and forming | CNC machining and milling operations |

| Precision Focus | Die alignment and press setup accuracy | Tool measurement and tool offset calibration |

| Equipment Used | Dial indicators, alignment tools, fixtures | Tool presetters, micrometers, digital measuring tools |

| Impact | Ensures proper die function and part consistency | Improves machining precision and tool life |

Overview: Die Setter vs Tool Setter Roles

Die setters primarily focus on installing, adjusting, and maintaining dies used in stamping presses, ensuring precise alignment and efficient production processes. Tool setters calibrate and inspect cutting tools, fixtures, and measuring devices to maintain accuracy in machining operations. Both roles are critical in manufacturing for optimizing equipment performance and minimizing downtime.

Key Responsibilities of Die Setters

Die setters specialize in installing, aligning, and maintaining dies used in manufacturing presses, ensuring precision for each production run. Their key responsibilities include adjusting die components to meet exact specifications, conducting routine inspections to prevent defects, and collaborating with production teams to optimize die performance. Mastery of blueprints, mechanical drawings, and press operation principles is essential for accurate die setup and efficient manufacturing processes.

Key Responsibilities of Tool Setters

Tool setters specialize in calibrating and maintaining precision machinery used in manufacturing processes, ensuring tools meet exact specifications for optimal performance. They are responsible for accurately setting up, adjusting, and inspecting cutting tools, dies, and fixtures to maintain quality and consistency in production. Regular monitoring and troubleshooting of tooling equipment minimize downtime and support seamless manufacturing operations.

Required Skills and Qualifications

Die setters require expertise in interpreting blueprints, operating stamping presses, and performing precise measurements with micrometers and calipers. Tool setters must possess advanced mechanical skills, proficiency in CNC programming, and experience with machine setup and calibration to ensure tooling accuracy. Both roles demand strong problem-solving abilities, attention to detail, and knowledge of safety protocols in manufacturing environments.

Typical Work Environments

Die setters typically operate in heavy manufacturing settings such as metal stamping or forging plants, where high-precision die adjustments are essential for maintaining equipment functionality. Tool setters usually work in machine shops or CNC machining centers, focusing on calibrating and measuring cutting tools to ensure machining accuracy. Both roles demand exposure to industrial environments with stringent safety protocols and the use of precision measurement instruments.

Safety Protocols and Best Practices

Die setters and tool setters must adhere to strict safety protocols such as wearing personal protective equipment (PPE), using machine guards, and following lockout/tagout procedures to prevent accidental machine startups. Best practices include regular inspection and maintenance of dies and tools to avoid malfunctions, thorough training on equipment handling, and implementing standardized communication methods for setup verification. Emphasizing ergonomic techniques and proper lifting procedures also reduces risks of injury during tool and die changes in manufacturing environments.

Tools and Equipment Used

Die setters primarily work with heavy stamping presses and large dies, utilizing hydraulic or mechanical presses, die cushions, and precision measuring tools such as dial indicators and micrometers to align and secure dies accurately. Tool setters focus on the setup and calibration of cutting tools on CNC machines, employing tool presetter devices, probe systems, and digital measuring instruments to ensure precise tool length and diameter measurements. Both roles demand expertise in handling specialized fixtures and gauges to maintain tight tolerances and optimize manufacturing efficiency.

Training and Certification Requirements

Die Setters require specialized training in press operation, die setup, and machine maintenance, often necessitating certification in safety protocols and mechanical skills. Tool Setters must possess expertise in precision measurement, tool calibration, and CNC programming, with certifications such as ISO 9001 or CNC operator credentials enhancing their qualifications. Both roles demand rigorous training programs emphasizing technical proficiency and adherence to industry standards for quality and safety.

Career Progression Opportunities

Die setters and tool setters both play critical roles in manufacturing, with distinct career progression paths. Die setters often advance to roles like die maintenance supervisor or toolroom manager due to their specialized skills in press setups and adjustments. Tool setters typically move towards CNC programmer or manufacturing engineer positions, leveraging their expertise in tooling precision and machine calibration.

Salary Expectations and Job Outlook

Die setters typically earn an average salary ranging from $40,000 to $60,000 per year, reflecting their specialized skills in aligning and installing dies within metal stamping processes. Tool setters, responsible for setting up and maintaining various machine tools, often see salaries between $38,000 and $58,000 annually, with variations based on industry and experience. Both roles demonstrate steady job outlooks driven by consistent demand in manufacturing sectors, but die setters may experience slightly higher growth potential due to the complexity and precision required in their tasks.

Die Setter vs Tool Setter Infographic

jobdiv.com

jobdiv.com