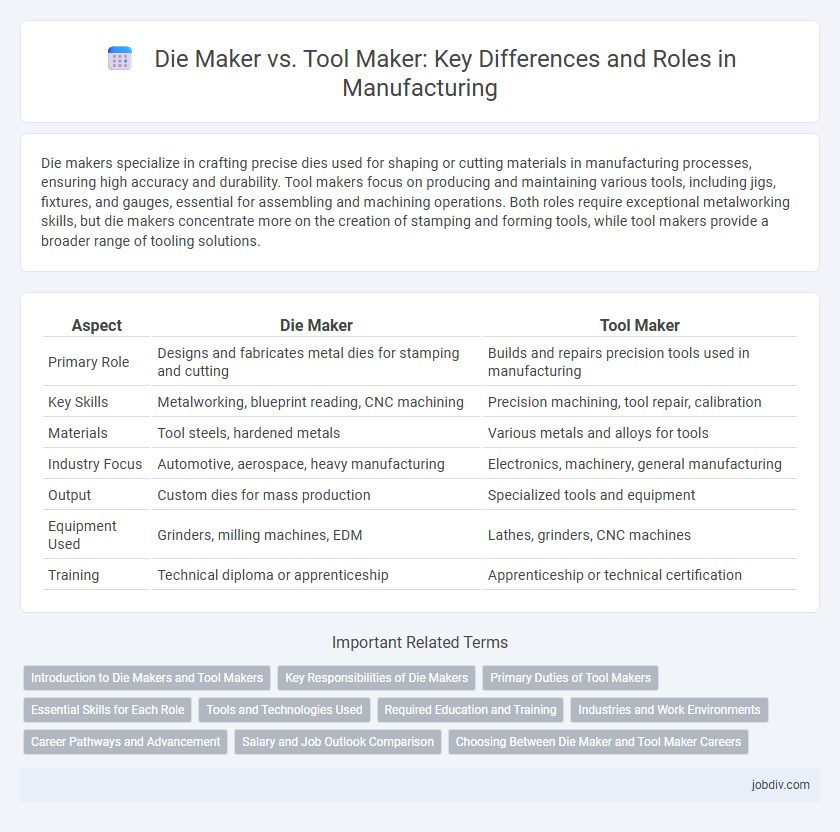

Die makers specialize in crafting precise dies used for shaping or cutting materials in manufacturing processes, ensuring high accuracy and durability. Tool makers focus on producing and maintaining various tools, including jigs, fixtures, and gauges, essential for assembling and machining operations. Both roles require exceptional metalworking skills, but die makers concentrate more on the creation of stamping and forming tools, while tool makers provide a broader range of tooling solutions.

Table of Comparison

| Aspect | Die Maker | Tool Maker |

|---|---|---|

| Primary Role | Designs and fabricates metal dies for stamping and cutting | Builds and repairs precision tools used in manufacturing |

| Key Skills | Metalworking, blueprint reading, CNC machining | Precision machining, tool repair, calibration |

| Materials | Tool steels, hardened metals | Various metals and alloys for tools |

| Industry Focus | Automotive, aerospace, heavy manufacturing | Electronics, machinery, general manufacturing |

| Output | Custom dies for mass production | Specialized tools and equipment |

| Equipment Used | Grinders, milling machines, EDM | Lathes, grinders, CNC machines |

| Training | Technical diploma or apprenticeship | Apprenticeship or technical certification |

Introduction to Die Makers and Tool Makers

Die makers specialize in creating precision dies used for shaping or cutting materials in manufacturing processes, ensuring high accuracy and durability in mass production. Tool makers focus on designing and fabricating custom tools, jigs, and fixtures that optimize manufacturing efficiency and product quality. Both roles require advanced skills in metallurgy, machining, and blueprint reading to support complex industrial operations.

Key Responsibilities of Die Makers

Die makers specialize in fabricating and assembling dies used in mass production processes such as stamping, cutting, and molding. Their key responsibilities include interpreting blueprints and technical drawings to produce precise die components, setting up and maintaining die machinery, and conducting regular inspections to ensure tool accuracy and durability. Die makers collaborate closely with engineers to modify and troubleshoot dies, optimizing manufacturing efficiency and product quality.

Primary Duties of Tool Makers

Tool makers specialize in fabricating, assembling, and repairing precision tools, dies, and molds essential for manufacturing processes. They interpret engineering designs and use machines like grinders, lathes, and milling machines to create customized tools that ensure product accuracy and efficiency. Their expertise directly supports production by maintaining quality standards and minimizing machine downtime.

Essential Skills for Each Role

Die makers require expertise in precision machining, blueprint reading, and metal fabrication to create dies that shape materials accurately in mass production. Tool makers specialize in designing, building, and maintaining various tools and jigs, necessitating skills in CAD software, tool grinding, and inspection techniques. Both roles demand strong problem-solving abilities, attention to detail, and a deep understanding of materials and manufacturing processes to ensure high-quality outputs.

Tools and Technologies Used

Die makers primarily utilize precision CNC machining, EDM (Electrical Discharge Machining), and grinding machines to create complex dies essential for shaping metal parts. Tool makers employ a broader range of technologies including milling machines, lathes, and CAD/CAM software to design and manufacture jigs, fixtures, and specialized tooling. Both professions rely heavily on advanced metrology instruments like CMM (Coordinate Measuring Machines) to ensure high precision and quality control in manufacturing processes.

Required Education and Training

Die makers typically require formal education in manufacturing technology or industrial engineering, often completing apprenticeships or technical school programs. Tool makers generally pursue similar educational paths but may emphasize precision machining and CNC programming through specialized training or certification courses. Both professions demand hands-on experience to master complex machinery and fabrication techniques essential for high-quality production.

Industries and Work Environments

Die makers primarily serve the automotive, aerospace, and heavy equipment industries, working in high-precision manufacturing environments where creating custom dies for stamping and forging is essential. Tool makers are crucial across diverse sectors like electronics, medical devices, and consumer goods, operating in workshops and factories focused on producing and maintaining molds, jigs, and fixtures with fine tolerances. Both professions demand expertise in CNC machining and metallurgy, but die makers often engage in large-scale production settings, whereas tool makers support varied product lines with specialized equipment.

Career Pathways and Advancement

Die makers specialize in creating precision dies for mass production, focusing on metal shaping processes, while tool makers design and maintain tools and equipment essential for various manufacturing operations. Career advancement for die makers often involves mastering complex die maintenance and repair, leading to supervisory roles or transitioning into tool design, whereas tool makers can progress to roles in tooling engineering or manufacturing management by enhancing skills in CNC programming and material science. Both career pathways demand continuous technical training and experience, with opportunities for specialization influencing long-term professional growth in advanced manufacturing environments.

Salary and Job Outlook Comparison

Die makers typically earn an average salary ranging from $45,000 to $70,000 annually, while tool makers can command higher wages, often between $55,000 and $80,000 depending on experience and specialization. The job outlook for tool makers is generally more robust due to their critical role in precision manufacturing and the increasing demand for advanced tooling in automotive and aerospace industries. Die makers face steady employment opportunities, but emerging automation technologies may impact long-term growth compared to tool makers, who benefit from evolving industry needs.

Choosing Between Die Maker and Tool Maker Careers

Choosing between a die maker and tool maker career depends on specialization and industry demands, with die makers focusing on precision cutting, shaping, and forming dies used in mass production, while tool makers design and maintain a broader range of tools and machinery components. Die makers typically require expertise in metallurgy and CNC machining to create complex dies, whereas tool makers emphasize versatility in fabricating and repairing jigs, fixtures, and gauges. Salary potential and job stability vary by region and industry, but both careers demand strong technical skills, problem-solving abilities, and adherence to tight manufacturing tolerances.

Die Maker vs Tool Maker Infographic

jobdiv.com

jobdiv.com