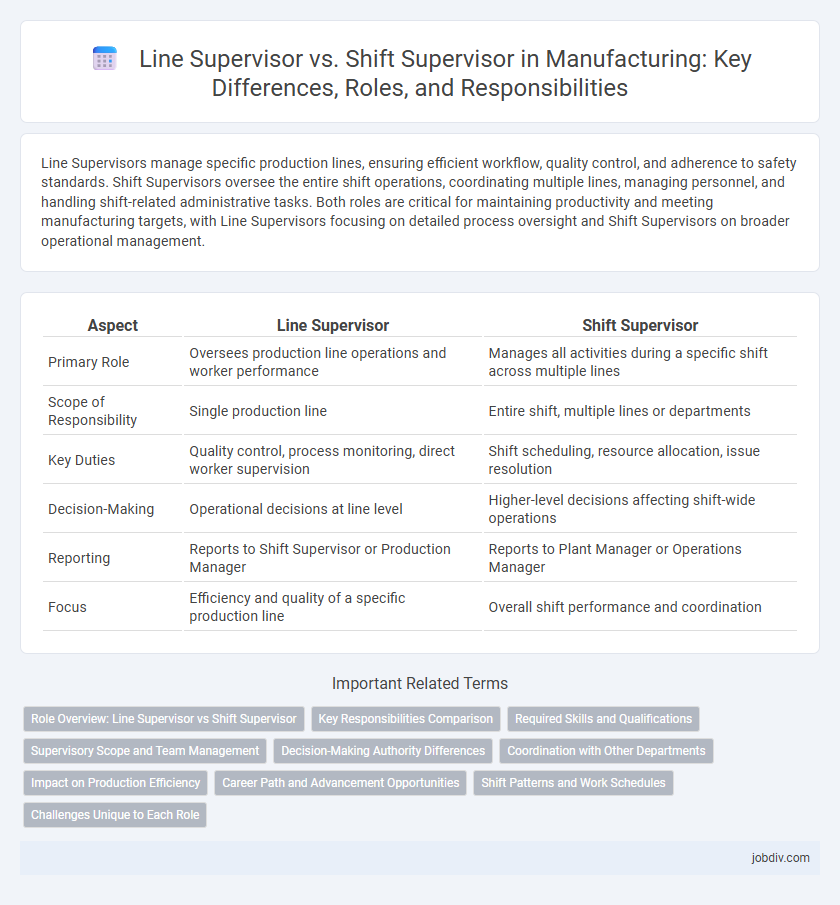

Line Supervisors manage specific production lines, ensuring efficient workflow, quality control, and adherence to safety standards. Shift Supervisors oversee the entire shift operations, coordinating multiple lines, managing personnel, and handling shift-related administrative tasks. Both roles are critical for maintaining productivity and meeting manufacturing targets, with Line Supervisors focusing on detailed process oversight and Shift Supervisors on broader operational management.

Table of Comparison

| Aspect | Line Supervisor | Shift Supervisor |

|---|---|---|

| Primary Role | Oversees production line operations and worker performance | Manages all activities during a specific shift across multiple lines |

| Scope of Responsibility | Single production line | Entire shift, multiple lines or departments |

| Key Duties | Quality control, process monitoring, direct worker supervision | Shift scheduling, resource allocation, issue resolution |

| Decision-Making | Operational decisions at line level | Higher-level decisions affecting shift-wide operations |

| Reporting | Reports to Shift Supervisor or Production Manager | Reports to Plant Manager or Operations Manager |

| Focus | Efficiency and quality of a specific production line | Overall shift performance and coordination |

Role Overview: Line Supervisor vs Shift Supervisor

Line Supervisors in manufacturing oversee specific production lines, ensuring operational efficiency, quality control, and adherence to safety standards during their assigned shifts. Shift Supervisors manage the entire production shift, coordinating multiple lines, resolving workforce issues, and maintaining overall workflow continuity. Line Supervisors focus on detailed task execution, while Shift Supervisors have broader responsibilities including personnel management and cross-line coordination.

Key Responsibilities Comparison

Line Supervisors manage specific production lines ensuring workflow efficiency, quality control, and operator performance. Shift Supervisors oversee the entire shift operations, coordinating multiple lines, managing shift schedules, and resolving production issues in real-time. Both roles require strong leadership, but Line Supervisors focus on detailed line-level tasks while Shift Supervisors handle broader operational management.

Required Skills and Qualifications

Line Supervisors require strong technical expertise in production processes, excellent communication skills, and proficiency in quality control to manage daily operations effectively. Shift Supervisors need advanced leadership abilities, experience in workforce management, and a solid understanding of safety regulations to oversee entire shifts and ensure consistent productivity. Both roles demand problem-solving skills and familiarity with manufacturing software, but Shift Supervisors typically hold higher-level certifications or degrees in industrial engineering or management.

Supervisory Scope and Team Management

Line Supervisors oversee specific production lines, directly managing machine operators and ensuring workflow efficiency within their designated segment. Shift Supervisors have a broader supervisory scope, managing multiple line supervisors and coordinating overall shift activities to meet production targets. Effective team management by Line Supervisors focuses on technical task execution, while Shift Supervisors emphasize strategic allocation of resources and cross-functional coordination.

Decision-Making Authority Differences

Line Supervisors primarily manage specific production processes and have decision-making authority related to operational tasks, quality control, and workforce coordination on the manufacturing floor. Shift Supervisors possess broader decision-making powers, overseeing entire shifts, including resource allocation, safety compliance, and addressing escalated issues that impact overall production efficiency. The key difference lies in the scope of authority, with Shift Supervisors making strategic decisions affecting multiple lines, while Line Supervisors focus on tactical decisions within their assigned production units.

Coordination with Other Departments

A Line Supervisor coordinates directly with production teams to ensure workflow efficiency while communicating daily output and issues to Quality Control and Maintenance departments. A Shift Supervisor oversees multiple lines within a shift, facilitating cross-department collaboration between Production, Logistics, and Safety teams to maintain overall operational continuity. Effective coordination from both roles enhances real-time problem-solving and adherence to production schedules across departments.

Impact on Production Efficiency

Line Supervisors directly manage specific production lines, ensuring timely operations and quality control, which leads to improved production efficiency through focused oversight. Shift Supervisors oversee entire shifts, coordinating multiple line supervisors and addressing broader operational issues, optimizing resource allocation and minimizing downtime across the production floor. Effective collaboration between Line and Shift Supervisors results in synchronized workflows, enhanced communication, and accelerated problem resolution, driving overall manufacturing productivity.

Career Path and Advancement Opportunities

Line Supervisors typically oversee specific production lines, focusing on operational efficiency and quality control, which builds specialized skills crucial for advancement into roles like Production Manager or Operations Supervisor. Shift Supervisors manage entire shifts, coordinating multiple lines and teams, offering broader leadership experience that primes them for higher management positions such as Plant Manager or Operations Director. Career progression for Line Supervisors often involves deepening technical expertise, while Shift Supervisors gain strategic oversight, each path providing unique competencies for ascending the manufacturing leadership ladder.

Shift Patterns and Work Schedules

Line Supervisors typically oversee production activities on a specific assembly line with fixed shift patterns aligned to standard operational hours, often maintaining consistent daily schedules. Shift Supervisors manage broader shifts across multiple lines or departments, working in rotating or variable shift patterns to ensure continuous coverage and operational efficiency. Work schedules for Shift Supervisors frequently include night, weekend, and holiday rotations, reflecting the need for 24/7 production supervision in manufacturing environments.

Challenges Unique to Each Role

Line Supervisors face challenges like managing real-time production issues, ensuring quality control, and coordinating machine operators on the manufacturing floor. Shift Supervisors handle broader responsibilities, including overseeing multiple lines, managing shift schedules, and addressing personnel conflicts during shift changes. Each role demands distinct problem-solving skills tailored to immediate operational efficiency versus overall shift management.

Line Supervisor vs Shift Supervisor Infographic

jobdiv.com

jobdiv.com