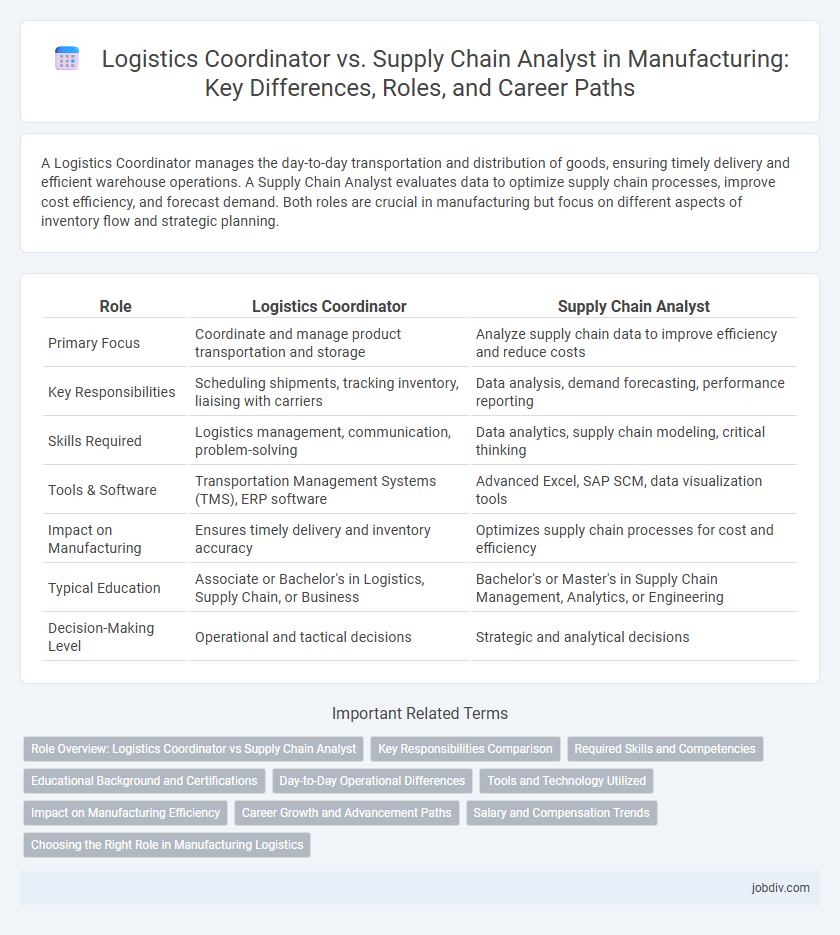

A Logistics Coordinator manages the day-to-day transportation and distribution of goods, ensuring timely delivery and efficient warehouse operations. A Supply Chain Analyst evaluates data to optimize supply chain processes, improve cost efficiency, and forecast demand. Both roles are crucial in manufacturing but focus on different aspects of inventory flow and strategic planning.

Table of Comparison

| Role | Logistics Coordinator | Supply Chain Analyst |

|---|---|---|

| Primary Focus | Coordinate and manage product transportation and storage | Analyze supply chain data to improve efficiency and reduce costs |

| Key Responsibilities | Scheduling shipments, tracking inventory, liaising with carriers | Data analysis, demand forecasting, performance reporting |

| Skills Required | Logistics management, communication, problem-solving | Data analytics, supply chain modeling, critical thinking |

| Tools & Software | Transportation Management Systems (TMS), ERP software | Advanced Excel, SAP SCM, data visualization tools |

| Impact on Manufacturing | Ensures timely delivery and inventory accuracy | Optimizes supply chain processes for cost and efficiency |

| Typical Education | Associate or Bachelor's in Logistics, Supply Chain, or Business | Bachelor's or Master's in Supply Chain Management, Analytics, or Engineering |

| Decision-Making Level | Operational and tactical decisions | Strategic and analytical decisions |

Role Overview: Logistics Coordinator vs Supply Chain Analyst

A Logistics Coordinator manages the efficient movement and storage of raw materials and finished goods within manufacturing facilities, ensuring timely delivery and minimizing delays. In contrast, a Supply Chain Analyst focuses on analyzing data to optimize supply chain processes, forecast demand, and reduce costs across procurement, production, and distribution. Both roles are pivotal in manufacturing but differ in hands-on operational management versus strategic analytical planning.

Key Responsibilities Comparison

Logistics Coordinators manage the day-to-day operations of inventory movement, shipment scheduling, and coordination with carriers to ensure timely delivery. Supply Chain Analysts focus on data analysis, forecasting demand, optimizing supply chain processes, and identifying cost-saving opportunities through advanced analytics tools. While Logistics Coordinators prioritize execution and operational efficiency, Supply Chain Analysts emphasize strategic planning and performance improvement across the supply network.

Required Skills and Competencies

A Logistics Coordinator requires strong organizational skills, proficiency in inventory management, and expertise in coordinating transportation and distribution processes to ensure efficient product flow. A Supply Chain Analyst needs advanced analytical abilities, experience with data modeling and demand forecasting, and proficiency in supply chain management software to optimize overall supply chain performance. Both roles demand excellent communication skills and problem-solving capabilities, but the analyst role places heavier emphasis on data interpretation and strategic planning.

Educational Background and Certifications

Logistics Coordinators typically hold a bachelor's degree in logistics, supply chain management, or business administration, with certifications such as Certified Logistics Associate (CLA) or Certified Supply Chain Professional (CSCP) enhancing their credentials. Supply Chain Analysts often possess degrees in industrial engineering, operations research, or data analytics, with certifications like Six Sigma Green Belt or APICS Certified in Planning and Inventory Management (CPIM) emphasizing analytical expertise. Both roles benefit from continuous professional development through industry-recognized certifications that align with evolving manufacturing logistics and supply chain technologies.

Day-to-Day Operational Differences

Logistics Coordinators manage daily shipping schedules, inventory tracking, and coordinate transport to ensure timely delivery within manufacturing operations. Supply Chain Analysts focus on data analysis, forecasting demand, and identifying inefficiencies to optimize the overall supply chain process. While Logistics Coordinators handle immediate operational tasks, Supply Chain Analysts drive strategic improvements based on performance metrics and market trends.

Tools and Technology Utilized

Logistics Coordinators primarily utilize transportation management systems (TMS) and warehouse management systems (WMS) to optimize shipment schedules and inventory flow within manufacturing operations. Supply Chain Analysts employ advanced analytics platforms, enterprise resource planning (ERP) software such as SAP or Oracle, and data visualization tools like Tableau to forecast demand and enhance supply chain efficiency. Both roles integrate IoT sensors and RFID technology to track assets in real time, but Supply Chain Analysts focus more on predictive modeling and data-driven decision-making.

Impact on Manufacturing Efficiency

A Logistics Coordinator streamlines the movement and storage of raw materials and finished goods, reducing delays and minimizing production downtime. A Supply Chain Analyst evaluates data to identify inefficiencies and optimize procurement, inventory levels, and distribution strategies, directly enhancing manufacturing throughput. Both roles contribute to operational agility, but the analyst's data-driven insights enable long-term efficiency improvements in production cycles.

Career Growth and Advancement Paths

Logistics Coordinators manage day-to-day transportation and inventory flows, providing foundational experience in operations that support career progression to roles such as Logistics Manager or Operations Supervisor. Supply Chain Analysts utilize data analytics and forecasting to optimize supply chain efficiency, positioning themselves for advancement into strategic roles like Supply Chain Manager or Business Intelligence Analyst. Both career paths offer growth opportunities, with Logistics Coordinators gaining operational expertise and Supply Chain Analysts developing analytical skills critical for leadership in manufacturing supply chain management.

Salary and Compensation Trends

Logistics Coordinators in manufacturing typically earn an average salary ranging from $45,000 to $60,000 annually, reflecting their role in managing transportation and inventory flow. Supply Chain Analysts command higher compensation, often between $65,000 and $85,000, due to their responsibilities in data analysis, demand forecasting, and process optimization. Recent trends indicate rising salaries for Supply Chain Analysts driven by increased reliance on data-driven decision-making and supply chain resilience initiatives in manufacturing sectors.

Choosing the Right Role in Manufacturing Logistics

Choosing between a Logistics Coordinator and a Supply Chain Analyst in manufacturing logistics depends on operational focus and data expertise. Logistics Coordinators manage day-to-day transportation, inventory control, and warehouse coordination, ensuring timely delivery and cost efficiency. Supply Chain Analysts leverage data analytics to optimize supply chain processes, forecast demand, and improve overall manufacturing logistics performance.

Logistics Coordinator vs Supply Chain Analyst Infographic

jobdiv.com

jobdiv.com