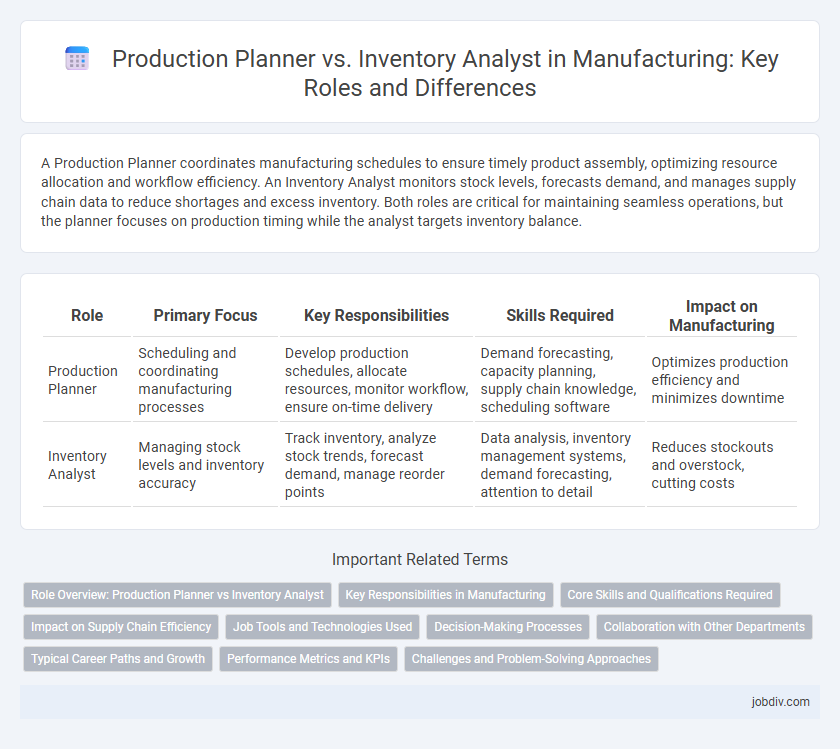

A Production Planner coordinates manufacturing schedules to ensure timely product assembly, optimizing resource allocation and workflow efficiency. An Inventory Analyst monitors stock levels, forecasts demand, and manages supply chain data to reduce shortages and excess inventory. Both roles are critical for maintaining seamless operations, but the planner focuses on production timing while the analyst targets inventory balance.

Table of Comparison

| Role | Primary Focus | Key Responsibilities | Skills Required | Impact on Manufacturing |

|---|---|---|---|---|

| Production Planner | Scheduling and coordinating manufacturing processes | Develop production schedules, allocate resources, monitor workflow, ensure on-time delivery | Demand forecasting, capacity planning, supply chain knowledge, scheduling software | Optimizes production efficiency and minimizes downtime |

| Inventory Analyst | Managing stock levels and inventory accuracy | Track inventory, analyze stock trends, forecast demand, manage reorder points | Data analysis, inventory management systems, demand forecasting, attention to detail | Reduces stockouts and overstock, cutting costs |

Role Overview: Production Planner vs Inventory Analyst

A Production Planner oversees scheduling manufacturing processes to ensure timely product completion, optimizing resource allocation and workflow efficiency. An Inventory Analyst focuses on monitoring stock levels, analyzing inventory data to prevent overstocking or shortages, and supporting cost-effective inventory management. Both roles are essential for synchronizing supply chain operations and maintaining production continuity in manufacturing environments.

Key Responsibilities in Manufacturing

Production Planners in manufacturing focus on scheduling and coordinating the production process to ensure efficient workflow, timely completion of orders, and optimal resource allocation. Inventory Analysts monitor inventory levels, analyze stock data, and manage reorder points to prevent stockouts or excess inventory, supporting continuous production. Both roles collaborate to balance production demands with inventory availability, driving operational efficiency and cost control.

Core Skills and Qualifications Required

A Production Planner requires expertise in demand forecasting, capacity planning, and scheduling software such as SAP or Oracle, with strong analytical and problem-solving skills to optimize manufacturing workflows. Inventory Analysts must possess proficiency in inventory management systems, data analysis, and supply chain coordination, emphasizing accuracy in stock control and cost reduction strategies. Both roles demand strong communication skills and proficiency in ERP tools, but Production Planners focus more on production process optimization, while Inventory Analysts prioritize inventory accuracy and turnover rates.

Impact on Supply Chain Efficiency

Production Planners optimize scheduling and resource allocation to ensure timely product delivery, directly enhancing production flow and reducing lead times. Inventory Analysts manage stock levels and accuracy, preventing overstocking or stockouts that disrupt supply chain continuity. Together, their roles synchronize production output with inventory availability, driving overall supply chain efficiency and responsiveness.

Job Tools and Technologies Used

Production Planners leverage advanced ERP systems like SAP and Oracle to optimize scheduling, resource allocation, and demand forecasting, ensuring efficient manufacturing workflows. Inventory Analysts utilize inventory management software such as NetSuite and Fishbowl Inventory, along with data analytics tools like Excel and Power BI, to monitor stock levels, track order cycles, and minimize carrying costs. Both roles rely on real-time data integration and automation technologies to enhance accuracy and operational efficiency in manufacturing environments.

Decision-Making Processes

Production Planners focus on scheduling and resource allocation to optimize manufacturing output, relying heavily on demand forecasts and capacity constraints for decision-making. Inventory Analysts analyze stock levels, turnover rates, and supplier lead times to ensure optimal inventory control and minimize carrying costs. Both roles leverage data-driven insights, but Production Planners prioritize production timelines while Inventory Analysts emphasize inventory accuracy and replenishment strategies.

Collaboration with Other Departments

Production planners coordinate closely with procurement, sales, and manufacturing teams to align production schedules with demand forecasts and resource availability. Inventory analysts collaborate with finance, supply chain, and warehouse departments to optimize inventory levels, control costs, and ensure stock accuracy. Both roles require effective communication and data sharing to enhance overall operational efficiency and meet organizational goals.

Typical Career Paths and Growth

Production Planners typically advance toward roles such as Operations Manager, Supply Chain Manager, or Plant Manager, leveraging expertise in workflow optimization and resource allocation. Inventory Analysts often progress into positions like Inventory Control Manager, Demand Planning Manager, or Procurement Manager, capitalizing on skills in data analysis, stock management, and supply forecasting. Both career paths offer growth opportunities in supply chain leadership, with increasing focus on integrated planning systems and strategic decision-making.

Performance Metrics and KPIs

Production Planners focus on KPIs such as production lead time, schedule adherence, and capacity utilization to optimize workflow and meet delivery deadlines efficiently. Inventory Analysts prioritize metrics like inventory turnover ratio, stock accuracy, and carrying costs to maintain optimal inventory levels and reduce holding expenses. Both roles rely on real-time data analytics and forecasting accuracy to enhance operational performance and minimize disruptions in the manufacturing supply chain.

Challenges and Problem-Solving Approaches

Production planners face challenges in balancing production schedules with fluctuating demand and machine downtime, requiring real-time data analysis and adaptive planning tools to optimize workflow efficiency. Inventory analysts address problems related to stock inaccuracies and supply chain disruptions by implementing advanced forecasting models and inventory management systems to minimize excess and shortages. Both roles rely heavily on cross-functional collaboration and continuous process improvements to align production goals with market needs.

Production Planner vs Inventory Analyst Infographic

jobdiv.com

jobdiv.com