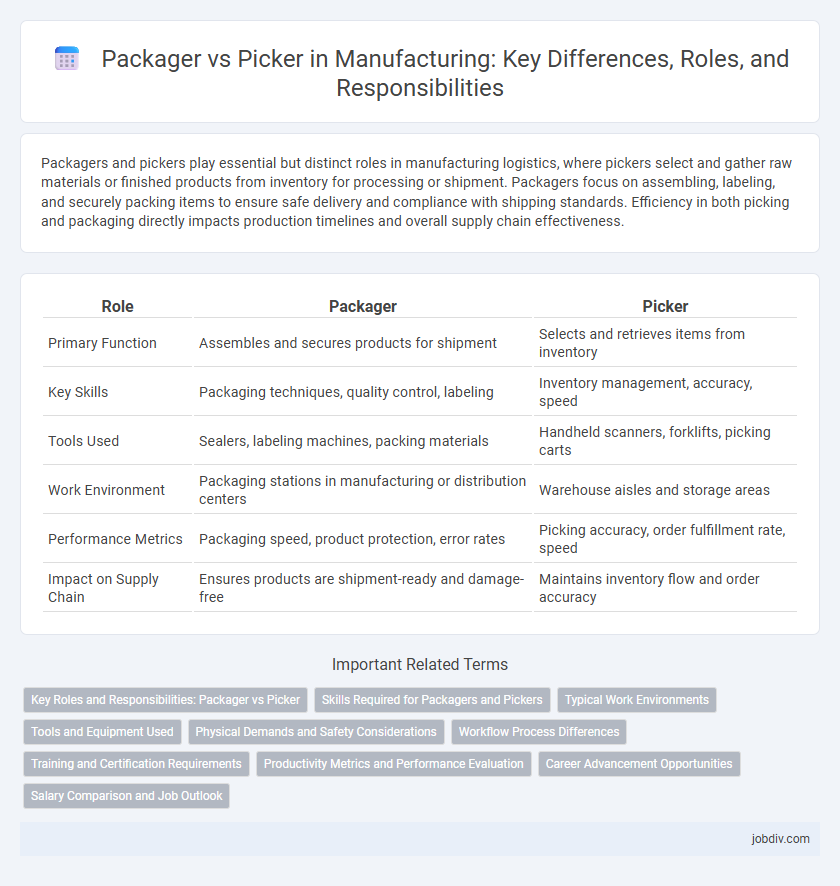

Packagers and pickers play essential but distinct roles in manufacturing logistics, where pickers select and gather raw materials or finished products from inventory for processing or shipment. Packagers focus on assembling, labeling, and securely packing items to ensure safe delivery and compliance with shipping standards. Efficiency in both picking and packaging directly impacts production timelines and overall supply chain effectiveness.

Table of Comparison

| Role | Packager | Picker |

|---|---|---|

| Primary Function | Assembles and secures products for shipment | Selects and retrieves items from inventory |

| Key Skills | Packaging techniques, quality control, labeling | Inventory management, accuracy, speed |

| Tools Used | Sealers, labeling machines, packing materials | Handheld scanners, forklifts, picking carts |

| Work Environment | Packaging stations in manufacturing or distribution centers | Warehouse aisles and storage areas |

| Performance Metrics | Packaging speed, product protection, error rates | Picking accuracy, order fulfillment rate, speed |

| Impact on Supply Chain | Ensures products are shipment-ready and damage-free | Maintains inventory flow and order accuracy |

Key Roles and Responsibilities: Packager vs Picker

Packagers in manufacturing focus on assembling, sealing, and labeling finished products to ensure they meet quality standards and are ready for shipment. Pickers are responsible for accurately selecting and retrieving raw materials or components from inventory based on production orders, which supports efficient workflow and inventory management. Both roles are critical in maintaining production line efficiency and fulfilling customer orders on time.

Skills Required for Packagers and Pickers

Packagers require skills in precision, attention to detail, and the ability to operate packaging machinery efficiently to ensure products are securely wrapped and labeled. Pickers need strong organizational skills, product knowledge, and proficiency with inventory management systems to accurately select items based on order specifications. Both roles demand physical stamina and basic quality control awareness to maintain smooth manufacturing operations.

Typical Work Environments

Packagers typically work in controlled environments such as manufacturing plants, warehouses, and distribution centers where products are assembled, sealed, and prepared for shipment. Pickers operate in fast-paced warehouse settings, fulfilling orders by retrieving items from storage shelves, often using handheld scanners or automated systems. Both roles demand attention to detail and efficiency, but packagers emphasize packaging accuracy while pickers prioritize order accuracy and speed.

Tools and Equipment Used

Packagers primarily use sealing machines, shrink wrappers, and labeling systems designed to prepare products for shipping and presentation. Pickers rely on handheld barcode scanners, pallet jacks, and order picking carts to efficiently locate and transport items within warehouses. Both roles integrate warehouse management software to enhance accuracy and workflow coordination.

Physical Demands and Safety Considerations

Packagers often face repetitive motion and heavy lifting, requiring ergonomic solutions to minimize strain and prevent musculoskeletal injuries, while pickers encounter brisk walking and frequent bending, increasing the risk of slips, trips, and falls. Both roles demand compliance with safety protocols such as proper lifting techniques and the use of personal protective equipment (PPE) to reduce injury risk in manufacturing environments. Implementing automated assistance and regular safety training can enhance worker well-being and operational efficiency in packaging and picking tasks.

Workflow Process Differences

Packagers focus on assembling, sealing, and labeling finished products to prepare them for shipment, ensuring accuracy and compliance with quality standards. Pickers handle order fulfillment by selecting items from inventory based on order specifications, often using scanners and warehouse management systems to optimize accuracy and speed. The workflow difference lies in packagers completing the final product stage, whereas pickers operate earlier in the supply chain, retrieving components.

Training and Certification Requirements

Packagers typically require training in machine operation, packaging standards, and quality control procedures, often supplemented by certifications in safety and materials handling. Pickers must be proficient in inventory management systems, manual material handling techniques, and occupational safety, with certifications like forklift operation or warehouse safety being advantageous. Both roles benefit from industry-specific training programs that emphasize efficiency, accuracy, and compliance with regulatory standards.

Productivity Metrics and Performance Evaluation

Packagers and pickers play distinct roles in manufacturing logistics, with productivity metrics centered on throughput rates and accuracy percentages. Pickers are evaluated based on order fulfillment speed and accuracy, directly impacting inventory turnover and reducing stockouts. Packagers' performance assessment relies on packaging speed, defect rates, and compliance with safety standards, influencing shipping efficiency and customer satisfaction.

Career Advancement Opportunities

Packagers typically perform repetitive manual tasks with limited scope for skill development, restricting long-term career growth in manufacturing. Pickers often gain experience with inventory management systems and logistics, providing a pathway to roles such as inventory control specialist or warehouse supervisor. Advanced careers in manufacturing logistics favor pickers due to their interaction with digital tools and operational decision-making responsibilities.

Salary Comparison and Job Outlook

Packagers in manufacturing typically earn an average salary ranging from $27,000 to $35,000 annually, while pickers often earn between $29,000 and $38,000, reflecting slight wage variations based on experience and location. Job outlook for pickers shows a moderate growth rate of about 5% over the next decade due to increased demand in warehouse automation and e-commerce fulfillment. Packagers face a more stable but slower growth rate near 3%, influenced by advancements in packaging technology and automation reducing manual labor needs.

Packager vs Picker Infographic

jobdiv.com

jobdiv.com