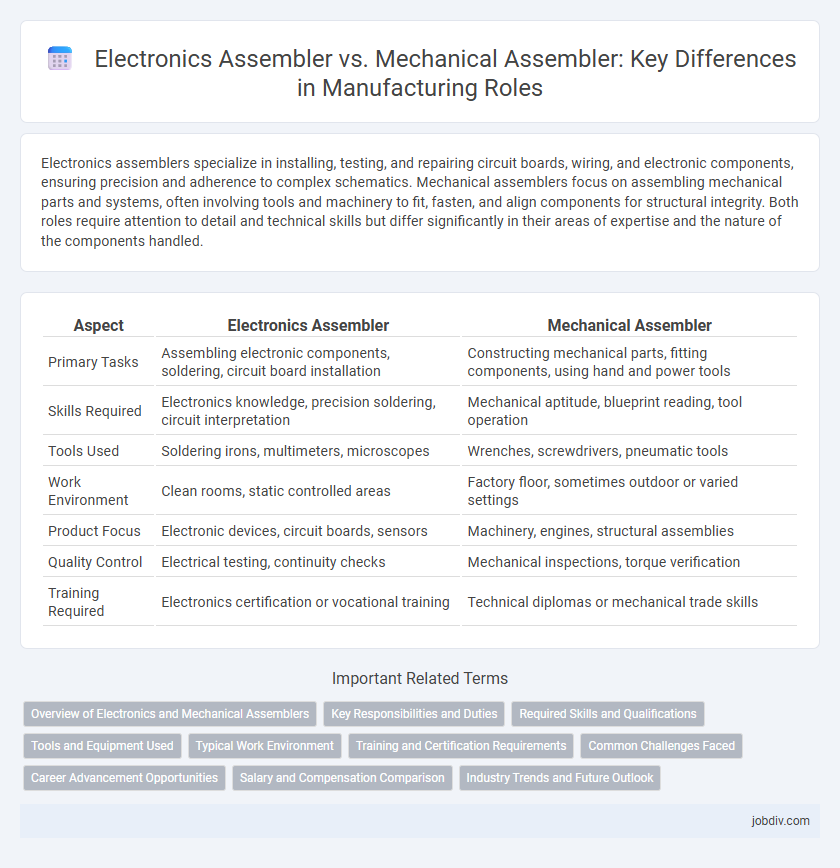

Electronics assemblers specialize in installing, testing, and repairing circuit boards, wiring, and electronic components, ensuring precision and adherence to complex schematics. Mechanical assemblers focus on assembling mechanical parts and systems, often involving tools and machinery to fit, fasten, and align components for structural integrity. Both roles require attention to detail and technical skills but differ significantly in their areas of expertise and the nature of the components handled.

Table of Comparison

| Aspect | Electronics Assembler | Mechanical Assembler |

|---|---|---|

| Primary Tasks | Assembling electronic components, soldering, circuit board installation | Constructing mechanical parts, fitting components, using hand and power tools |

| Skills Required | Electronics knowledge, precision soldering, circuit interpretation | Mechanical aptitude, blueprint reading, tool operation |

| Tools Used | Soldering irons, multimeters, microscopes | Wrenches, screwdrivers, pneumatic tools |

| Work Environment | Clean rooms, static controlled areas | Factory floor, sometimes outdoor or varied settings |

| Product Focus | Electronic devices, circuit boards, sensors | Machinery, engines, structural assemblies |

| Quality Control | Electrical testing, continuity checks | Mechanical inspections, torque verification |

| Training Required | Electronics certification or vocational training | Technical diplomas or mechanical trade skills |

Overview of Electronics and Mechanical Assemblers

Electronics Assemblers specialize in assembling circuit boards, wiring harnesses, and electronic components, using tools such as soldering irons and testing equipment to ensure functionality and precision. Mechanical Assemblers focus on constructing machinery and equipment by fitting mechanical parts, such as gears, shafts, and fasteners, often utilizing hand tools, power tools, and blueprints. Both roles require attention to detail and adherence to safety protocols, but Electronics Assemblers demand skills in handling delicate electronic components, whereas Mechanical Assemblers prioritize mechanical aptitude and assembly techniques.

Key Responsibilities and Duties

Electronics assemblers specialize in assembling, testing, and troubleshooting electronic components, ensuring precise soldering and adherence to circuit diagrams to maintain product quality and functionality. Mechanical assemblers focus on fitting, aligning, and securing mechanical parts using hand tools and machinery, following blueprints to build durable and accurate assemblies for automotive, aerospace, and industrial equipment. Both roles require strict compliance with safety protocols and quality control standards to maximize efficiency and minimize defects in the manufacturing process.

Required Skills and Qualifications

Electronics Assemblers require proficiency in reading electronic schematics, soldering, and handling delicate components, with skills in circuit board assembly and testing being essential. Mechanical Assemblers need expertise in interpreting mechanical blueprints, using hand and power tools, and assembling metal or plastic parts with precision. Both roles demand attention to detail, manual dexterity, and familiarity with safety protocols, but Electronics Assemblers often require basic electronics knowledge or certification, whereas Mechanical Assemblers typically benefit from experience with mechanical systems or relevant vocational training.

Tools and Equipment Used

Electronics assemblers primarily use precision soldering irons, wire strippers, multimeters, and oscilloscopes to assemble and test circuit boards and electronic components. Mechanical assemblers rely on hand tools such as wrenches, screwdrivers, torque tools, pneumatic drills, and hydraulic presses to fit and secure mechanical parts of machines and structures. Both roles require specialized equipment tailored to their specific assembly processes, highlighting the difference in technical skills and tool proficiency within manufacturing environments.

Typical Work Environment

Electronics Assemblers typically work in cleanrooms or climate-controlled environments to protect sensitive electronic components, often seated at workstations with precision tools and soldering equipment. Mechanical Assemblers usually operate on manufacturing floors or assembly lines, interacting with heavy machinery, hand tools, and robotic devices in louder, more spacious settings. Both roles demand adherence to safety protocols, but the electronics environment emphasizes static control and contamination prevention, while mechanical assembly prioritizes physical safety and ergonomics.

Training and Certification Requirements

Electronics Assemblers typically require specialized training in circuitry, soldering techniques, and electronic component handling, often supported by certifications such as IPC-A-610 or CETa (Certified Electronics Technician). Mechanical Assemblers focus on skills related to interpreting blueprints, assembling mechanical parts, and operating machinery, with certifications like NIMS (National Institute for Metalworking Skills) or OSHA safety standards being common. Both roles benefit from hands-on apprenticeships and technical education, but Electronics Assemblers demand more extensive knowledge of electronic systems and quality standards in manufacturing environments.

Common Challenges Faced

Electronics assemblers often face challenges such as handling delicate components that require precise soldering, managing electrostatic discharge risks, and maintaining strict adherence to circuit designs. Mechanical assemblers commonly encounter difficulties with aligning parts accurately, ensuring fastener tightness, and working with heavy or awkward components that demand physical strength and ergonomic attention. Both roles must navigate quality control pressures, time constraints, and the need for consistent assembly standards to meet manufacturing efficiency and product reliability goals.

Career Advancement Opportunities

Electronics Assemblers often experience faster career advancement due to the increasing demand for skilled professionals in high-tech industries like semiconductor and consumer electronics manufacturing. Mechanical Assemblers benefit from diverse opportunities in automotive, aerospace, and heavy machinery sectors, where expertise in complex mechanical systems can lead to supervisory and engineering roles. Both fields demand continuous skill development, but Electronics Assemblers typically engage more with emerging technologies such as robotics and automation, potentially accelerating progression into specialized technical or management positions.

Salary and Compensation Comparison

Electronics assemblers typically earn a median salary of $41,000 annually, with compensation influenced by technical skill in soldering and circuit board assembly. Mechanical assemblers often receive a slightly higher median wage around $44,000, reflecting expertise in fitting, aligning, and fastening mechanical parts. Both roles offer varied benefits, but mechanical assemblers may access overtime pay more frequently due to demand in heavy manufacturing sectors.

Industry Trends and Future Outlook

Electronics assemblers face growing demand due to the rise of IoT devices and advanced semiconductor manufacturing, emphasizing precision soldering and circuit testing skills. Mechanical assemblers increasingly integrate automation and robotics into assembly lines, requiring expertise in CNC machinery and CAD-driven part fitting. Future industry trends highlight a hybrid skill set combining electronics and mechanical knowledge, driven by smart manufacturing and Industry 4.0 technologies.

Electronics Assembler vs Mechanical Assembler Infographic

jobdiv.com

jobdiv.com