A CNC machinist operates and maintains CNC machines, interpreting blueprints and setting up tools to produce precise metal parts. A CNC programmer writes and tests the code that controls the machine's movements, optimizing processes for efficiency and accuracy. Collaboration between machinists and programmers ensures high-quality production and minimizes errors in manufacturing workflows.

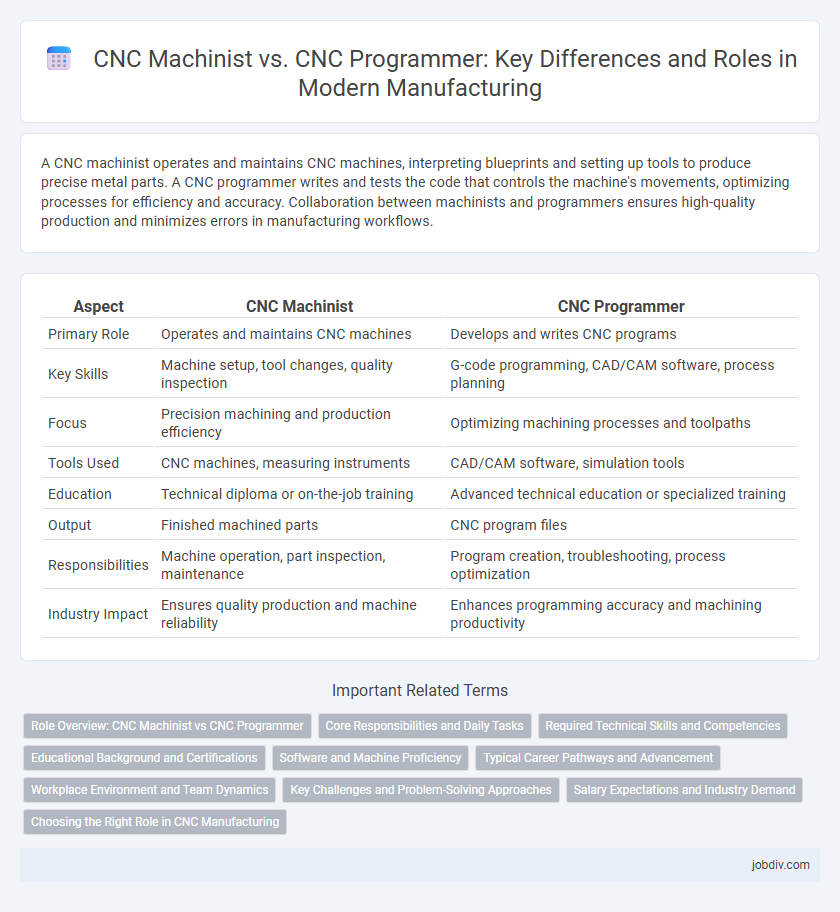

Table of Comparison

| Aspect | CNC Machinist | CNC Programmer |

|---|---|---|

| Primary Role | Operates and maintains CNC machines | Develops and writes CNC programs |

| Key Skills | Machine setup, tool changes, quality inspection | G-code programming, CAD/CAM software, process planning |

| Focus | Precision machining and production efficiency | Optimizing machining processes and toolpaths |

| Tools Used | CNC machines, measuring instruments | CAD/CAM software, simulation tools |

| Education | Technical diploma or on-the-job training | Advanced technical education or specialized training |

| Output | Finished machined parts | CNC program files |

| Responsibilities | Machine operation, part inspection, maintenance | Program creation, troubleshooting, process optimization |

| Industry Impact | Ensures quality production and machine reliability | Enhances programming accuracy and machining productivity |

Role Overview: CNC Machinist vs CNC Programmer

A CNC Machinist operates and maintains CNC machines to produce precision parts according to technical drawings, ensuring tooling setup, machine calibration, and quality control. A CNC Programmer writes and tests G-code programs to instruct CNC machines on cutting paths, speeds, and tool changes, optimizing manufacturing processes for efficiency and accuracy. While the machinist focuses on machine operation and part inspection, the programmer emphasizes software coding and process planning to maximize machine performance.

Core Responsibilities and Daily Tasks

CNC machinists operate and maintain CNC machines, ensuring precision in cutting, shaping, and finishing metal or plastic parts according to technical specifications. CNC programmers develop and optimize the computer code (G-code) that guides these machines, translating design blueprints into executable instructions. Both roles require a strong understanding of CAD/CAM software, machine tools, and quality control procedures to produce accurate and efficient manufacturing outputs.

Required Technical Skills and Competencies

CNC machinists require hands-on expertise in machine setup, tool selection, and precision measurement to operate CNC equipment efficiently. CNC programmers must possess advanced skills in G-code programming, CAD/CAM software, and process simulation for accurate tool path generation and optimization. Both roles demand a deep understanding of materials, machining processes, and quality control standards for high-precision manufacturing.

Educational Background and Certifications

CNC Machinists typically require vocational training or an associate degree in manufacturing technology, along with certifications like the National Institute for Metalworking Skills (NIMS) credential. CNC Programmers often hold a bachelor's degree in engineering or computer science and acquire advanced certifications such as Siemens or Fanuc CNC programming certificates. Both roles benefit from continuous education in CAD/CAM software and machining processes to stay current with industry standards.

Software and Machine Proficiency

CNC machinists excel in operating and maintaining CNC machines, relying on hands-on skills and software such as Fanuc or Haas to execute precise machining tasks. CNC programmers specialize in creating and optimizing CNC code using CAD/CAM software like Mastercam, SolidWorks, or Fusion 360 to design toolpaths and ensure efficient production. Mastery of these software tools directly impacts machine accuracy, cycle time, and overall manufacturing quality.

Typical Career Pathways and Advancement

CNC Machinists typically start by mastering machine setup, operation, and maintenance before advancing to lead machinist or supervisory roles, emphasizing hands-on technical skills. CNC Programmers often begin as machinists or with CAD/CAM software training and progress toward senior programming, engineering, or manufacturing management positions, focusing on creating efficient machining instructions. Career advancement for both roles depends on technical expertise, continuous learning, and adapting to emerging CNC technologies like multi-axis machining and automation.

Workplace Environment and Team Dynamics

CNC machinists operate and maintain CNC machines within dynamic manufacturing floors, collaborating directly with operators, engineers, and quality control teams to ensure precision and efficiency. CNC programmers often work in collaborative office or lab settings, developing and optimizing machine codes while coordinating with machinists and production managers to translate design specifications into executable programs. Both roles require strong communication and teamwork, fostering a seamless integration between software programming and hands-on machining in the industrial production environment.

Key Challenges and Problem-Solving Approaches

CNC Machinists face challenges such as maintaining precise tool calibration and troubleshooting machine malfunctions on the shop floor, requiring hands-on problem-solving and quick adjustments to minimize downtime. CNC Programmers encounter difficulties in optimizing complex toolpath coding and addressing software compatibility issues, relying heavily on simulation software and iterative testing to enhance efficiency. Both roles demand deep technical knowledge and collaboration to ensure seamless production and high-quality manufactured parts.

Salary Expectations and Industry Demand

CNC Machinists typically earn between $45,000 and $65,000 annually, while CNC Programmers command higher salaries ranging from $60,000 to $85,000 due to their advanced technical skills. The manufacturing industry shows strong demand for CNC Programmers as automation and precision manufacturing increase, driving growth in programming roles. Both careers experience consistent job opportunities, but CNC Programming offers greater salary potential and upward mobility in advanced manufacturing environments.

Choosing the Right Role in CNC Manufacturing

Choosing the right role in CNC manufacturing depends on your technical skills and career goals, as CNC machinists operate and maintain machines to produce precision parts, while CNC programmers design and code the instructions for these machines to follow. Understanding the differences in responsibilities, with machinists focusing on hands-on machine setup and operation and programmers concentrating on software and toolpath development, helps optimize production efficiency and accuracy. Employers prioritize candidates with expertise in CAD/CAM software for programming roles and strong mechanical aptitude for machining positions to meet the demands of modern manufacturing workflows.

CNC Machinist vs CNC Programmer Infographic

jobdiv.com

jobdiv.com