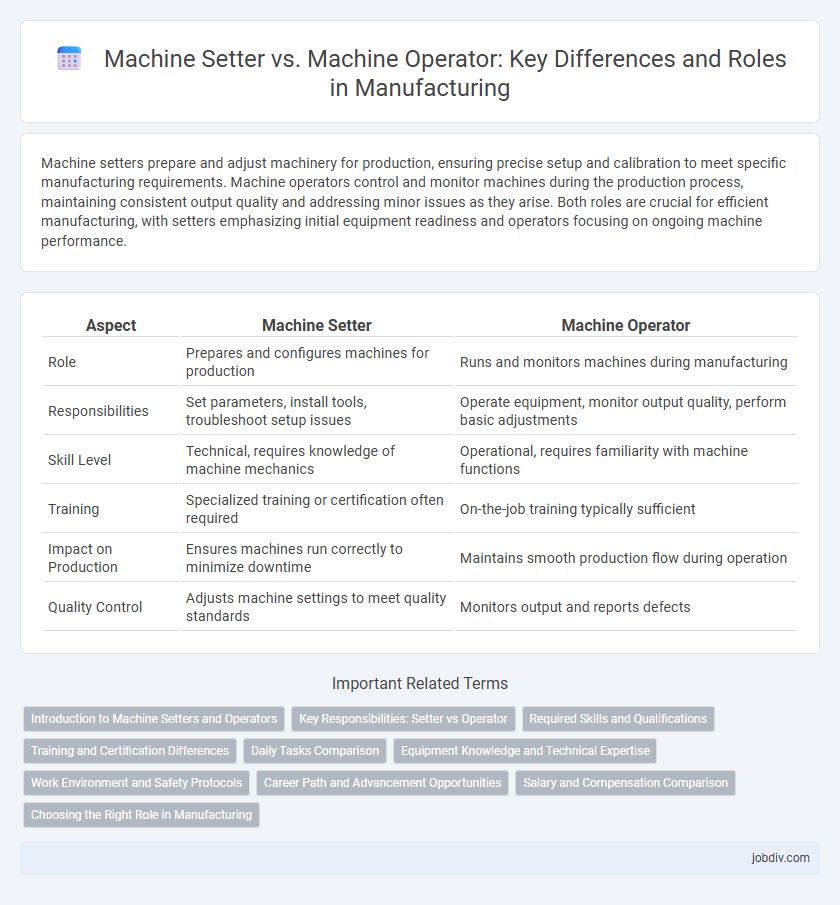

Machine setters prepare and adjust machinery for production, ensuring precise setup and calibration to meet specific manufacturing requirements. Machine operators control and monitor machines during the production process, maintaining consistent output quality and addressing minor issues as they arise. Both roles are crucial for efficient manufacturing, with setters emphasizing initial equipment readiness and operators focusing on ongoing machine performance.

Table of Comparison

| Aspect | Machine Setter | Machine Operator |

|---|---|---|

| Role | Prepares and configures machines for production | Runs and monitors machines during manufacturing |

| Responsibilities | Set parameters, install tools, troubleshoot setup issues | Operate equipment, monitor output quality, perform basic adjustments |

| Skill Level | Technical, requires knowledge of machine mechanics | Operational, requires familiarity with machine functions |

| Training | Specialized training or certification often required | On-the-job training typically sufficient |

| Impact on Production | Ensures machines run correctly to minimize downtime | Maintains smooth production flow during operation |

| Quality Control | Adjusts machine settings to meet quality standards | Monitors output and reports defects |

Introduction to Machine Setters and Operators

Machine setters configure and adjust machinery to ensure optimal production quality and efficiency, requiring specialized knowledge of machine specifications and calibration techniques. Machine operators focus on running machines during the manufacturing process, monitoring performance, and maintaining consistent output according to established standards. Both roles are essential in manufacturing environments, with setters preparing machines for operation and operators managing the continuous production workflow.

Key Responsibilities: Setter vs Operator

Machine setters are responsible for adjusting and calibrating equipment to prepare manufacturing machines for specific production runs, ensuring precision and compliance with technical specifications. Machine operators primarily manage the continuous running of machinery, monitoring performance, detecting malfunctions, and maintaining quality control during production. Both roles require collaboration to optimize machine efficiency, minimize downtime, and support consistent product output.

Required Skills and Qualifications

Machine setters require advanced skills in equipment calibration, mathematical problem-solving, and blueprint reading to ensure precise adjustments before production runs. Machine operators must have a strong understanding of machine operation, quality control, and basic troubleshooting to maintain consistent output during manufacturing processes. Both roles typically demand technical certifications and hands-on experience in manufacturing environments to ensure safety and efficiency.

Training and Certification Differences

Machine setters typically require specialized training on equipment setup, calibration, and troubleshooting, often including certification programs like the National Institute for Metalworking Skills (NIMS) credentials. Machine operators focus more on running and monitoring machines during production, with training centered around safety protocols and operational efficiency, sometimes necessitating certifications like OSHA safety training. The distinct certification requirements reflect the machine setters' technical responsibilities in machine preparation compared to the operators' emphasis on maintaining continuous production flow.

Daily Tasks Comparison

Machine setters calibrate and adjust machinery to ensure optimal performance before production begins, performing tasks such as tool alignment and equipment setup. Machine operators run and monitor production machines during the manufacturing process, checking for defects and maintaining consistent output quality. While setters focus on preparation and fine-tuning, operators concentrate on continuous operation and troubleshooting throughout the production cycle.

Equipment Knowledge and Technical Expertise

Machine Setters possess in-depth equipment knowledge, including the ability to calibrate and adjust machinery to meet production specifications, ensuring optimal performance and minimal downtime. Machine Operators, while skilled in operating and monitoring equipment, typically follow predefined settings and protocols rather than performing complex setup tasks. Technical expertise of Machine Setters includes troubleshooting mechanical issues and implementing production changes, whereas Operators focus on maintaining steady workflow and quality control during operation.

Work Environment and Safety Protocols

Machine setters typically work in controlled manufacturing environments where setting up and calibrating equipment requires strict adherence to safety protocols such as lockout/tagout procedures to prevent accidental machine startups. Machine operators often perform repetitive tasks on production lines, where personal protective equipment (PPE) and continuous monitoring of safety measures like emergency stop functions are critical to minimizing injury risks. Both roles demand awareness of workplace hazards including noise, moving parts, and potential exposure to chemicals, emphasizing compliance with OSHA regulations and company safety standards.

Career Path and Advancement Opportunities

Machine setters primarily focus on preparing and adjusting equipment before production, offering foundational skills that lead to supervisory or technician roles. Machine operators manage the ongoing operation of machinery and often advance into lead operator or maintenance positions through experience and skill enhancement. Both career paths provide varied advancement opportunities but differ in specialization and technical expertise required.

Salary and Compensation Comparison

Machine setters typically earn higher salaries than machine operators due to their specialized skills in configuring and adjusting equipment prior to production. According to industry data, machine setters in manufacturing report average annual earnings ranging from $45,000 to $60,000, while machine operators usually earn between $30,000 and $45,000. Compensation packages for machine setters often include bonuses and overtime pay, reflecting their critical role in ensuring machine precision and minimizing downtime.

Choosing the Right Role in Manufacturing

Choosing the right role in manufacturing depends on skill level and responsibilities; machine setters require technical expertise to adjust and calibrate machinery for optimal performance, while machine operators focus on running and monitoring equipment during production. Machine setters often handle setup tasks that influence product quality and efficiency, making their role critical for minimizing downtime and defects. Operators play a key role in maintaining continuous workflow and ensuring safety standards, aligning with companies prioritizing consistent output and operational stability.

Machine Setter vs Machine Operator Infographic

jobdiv.com

jobdiv.com