A Maintenance Technician specializes in troubleshooting, repairing, and maintaining manufacturing equipment to ensure optimal production efficiency and minimize downtime. In contrast, a Facilities Technician focuses on the upkeep of the building infrastructure, including HVAC systems, electrical networks, and plumbing, to support a safe and functional work environment. Both roles are essential for seamless manufacturing operations, but they differ in their specific technical responsibilities and areas of expertise.

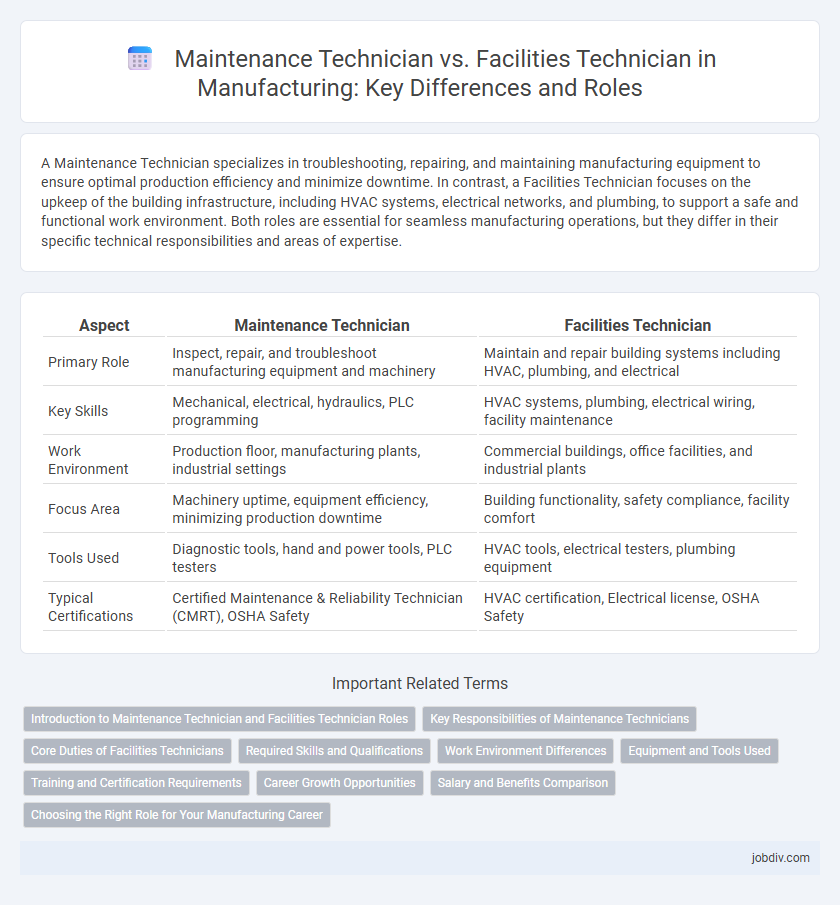

Table of Comparison

| Aspect | Maintenance Technician | Facilities Technician |

|---|---|---|

| Primary Role | Inspect, repair, and troubleshoot manufacturing equipment and machinery | Maintain and repair building systems including HVAC, plumbing, and electrical |

| Key Skills | Mechanical, electrical, hydraulics, PLC programming | HVAC systems, plumbing, electrical wiring, facility maintenance |

| Work Environment | Production floor, manufacturing plants, industrial settings | Commercial buildings, office facilities, and industrial plants |

| Focus Area | Machinery uptime, equipment efficiency, minimizing production downtime | Building functionality, safety compliance, facility comfort |

| Tools Used | Diagnostic tools, hand and power tools, PLC testers | HVAC tools, electrical testers, plumbing equipment |

| Typical Certifications | Certified Maintenance & Reliability Technician (CMRT), OSHA Safety | HVAC certification, Electrical license, OSHA Safety |

Introduction to Maintenance Technician and Facilities Technician Roles

Maintenance Technicians are responsible for diagnosing, repairing, and maintaining mechanical and electrical equipment within manufacturing plants, ensuring optimal operational efficiency. Facilities Technicians focus on the upkeep and servicing of building systems such as HVAC, plumbing, and electrical infrastructure to support a safe and functional work environment. Both roles are critical for minimizing downtime and enhancing productivity in manufacturing operations.

Key Responsibilities of Maintenance Technicians

Maintenance Technicians in manufacturing primarily focus on diagnosing, repairing, and maintaining production machinery to ensure optimal operational efficiency and minimize downtime. Their key responsibilities include troubleshooting mechanical, electrical, and hydraulic systems, performing preventive maintenance, and conducting routine inspections to detect potential issues early. Unlike Facilities Technicians who manage building systems such as HVAC, plumbing, and general infrastructure, Maintenance Technicians specialize in keeping complex manufacturing equipment running smoothly.

Core Duties of Facilities Technicians

Facilities Technicians primarily focus on maintaining the physical infrastructure and equipment essential for manufacturing operations, including HVAC systems, plumbing, electrical wiring, and building repairs. They conduct routine inspections, perform preventive maintenance, and respond to facility-related issues to ensure a safe and efficient working environment. Unlike Maintenance Technicians who often specialize in specific machinery, Facilities Technicians handle a broad range of building systems to support overall plant functionality.

Required Skills and Qualifications

Maintenance Technicians require expertise in machinery repair, mechanical systems, and electrical troubleshooting, often holding certifications such as HVAC or industrial maintenance. Facilities Technicians need skills in building systems management, including HVAC, plumbing, and electrical maintenance, with qualifications emphasizing facility operations and safety protocols. Both roles demand strong problem-solving abilities, knowledge of safety standards, and experience with preventive maintenance practices in manufacturing environments.

Work Environment Differences

Maintenance Technicians primarily operate on the manufacturing floor, working directly with production machinery and equipment, often in noisy, temperature-variable, and safety-sensitive environments. Facilities Technicians typically work in office buildings, warehouses, or facility infrastructure, maintaining HVAC systems, electrical networks, and building integrity in more controlled, less hazardous settings. The work environment for Maintenance Technicians demands specialized mechanical and technical skills in industrial contexts, whereas Facilities Technicians require broader building system knowledge suited to commercial or institutional spaces.

Equipment and Tools Used

Maintenance Technicians primarily use diagnostic tools, handheld meters, and specialized repair equipment to troubleshoot and maintain complex machinery within manufacturing plants. Facilities Technicians operate a broader range of tools including HVAC systems controls, building automation systems, and general hand tools to ensure infrastructure and utility systems function efficiently. Both roles require proficiency in technical equipment, but Maintenance Technicians concentrate on precise machinery calibration while Facilities Technicians focus on overall facility functionality and support systems.

Training and Certification Requirements

Maintenance Technicians typically require vocational training or an associate degree in industrial maintenance, with certifications such as OSHA safety, electrical, or HVAC credentials enhancing their expertise. Facilities Technicians usually need specialized training in building systems management, including certifications like Certified Facility Manager (CFM) or Building Operator Certification (BOC). Both roles demand ongoing professional development, but Maintenance Technicians emphasize mechanical and electrical skills, whereas Facilities Technicians focus more on infrastructure systems and compliance standards.

Career Growth Opportunities

Maintenance Technicians in manufacturing primarily focus on repairing and maintaining production machinery, offering career growth opportunities through specialized technical certifications and advancement to roles such as Maintenance Supervisor or Reliability Engineer. Facilities Technicians manage building systems like HVAC, electrical, and plumbing, with career progression pathways leading to Facilities Manager or Environmental Health and Safety (EHS) Specialist positions. Both roles benefit from cross-training, expanding skill sets, and gaining expertise in predictive maintenance and automation technologies to enhance career advancement prospects.

Salary and Benefits Comparison

Maintenance Technicians in manufacturing typically earn salaries ranging from $45,000 to $65,000 annually, reflecting specialized skills in equipment repair and preventive maintenance. Facilities Technicians, responsible for general building upkeep, usually have a salary range of $40,000 to $55,000, with benefits often including health insurance, retirement plans, and paid leave. Both roles may offer overtime pay and opportunities for skill-based bonuses, but Maintenance Technicians generally receive higher compensation due to the technical nature of their work.

Choosing the Right Role for Your Manufacturing Career

Maintenance technicians specialize in equipment repair, troubleshooting machinery, and ensuring operational efficiency on the production floor, making them essential for minimizing downtime in manufacturing plants. Facilities technicians focus on maintaining building systems such as HVAC, plumbing, and electrical infrastructure, which support the overall manufacturing environment and safety compliance. Choosing the right role depends on your expertise in mechanical systems versus facility management, with career advancement opportunities aligned to your technical skills and interest in either machinery maintenance or infrastructure support.

Maintenance Technician vs Facilities Technician Infographic

jobdiv.com

jobdiv.com