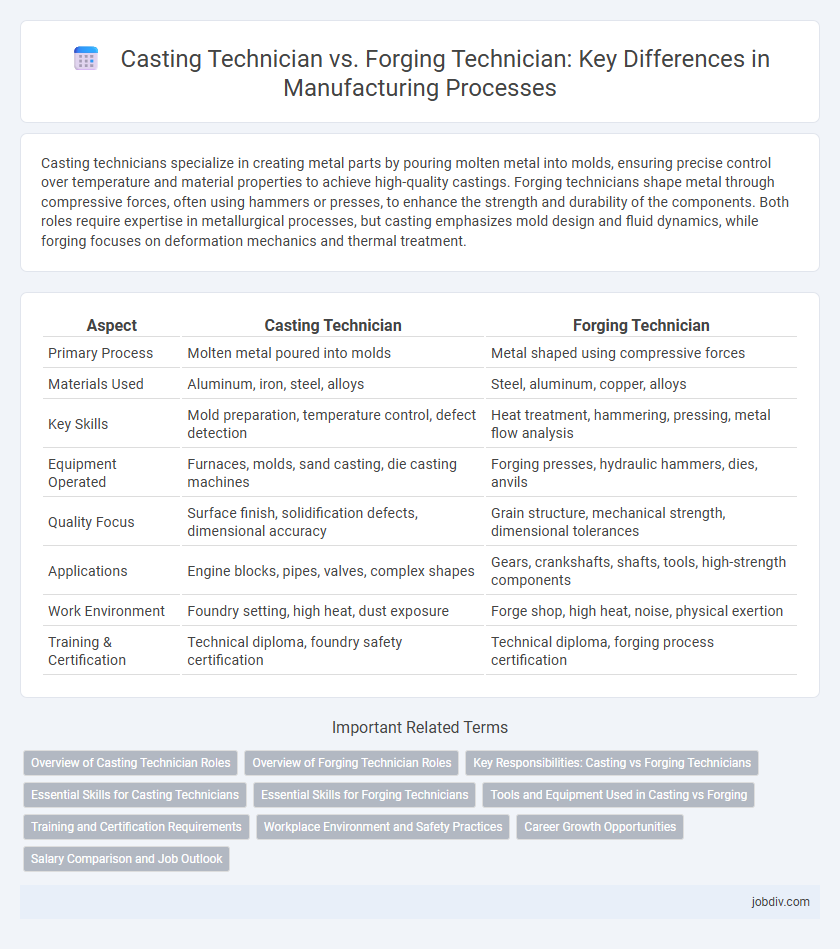

Casting technicians specialize in creating metal parts by pouring molten metal into molds, ensuring precise control over temperature and material properties to achieve high-quality castings. Forging technicians shape metal through compressive forces, often using hammers or presses, to enhance the strength and durability of the components. Both roles require expertise in metallurgical processes, but casting emphasizes mold design and fluid dynamics, while forging focuses on deformation mechanics and thermal treatment.

Table of Comparison

| Aspect | Casting Technician | Forging Technician |

|---|---|---|

| Primary Process | Molten metal poured into molds | Metal shaped using compressive forces |

| Materials Used | Aluminum, iron, steel, alloys | Steel, aluminum, copper, alloys |

| Key Skills | Mold preparation, temperature control, defect detection | Heat treatment, hammering, pressing, metal flow analysis |

| Equipment Operated | Furnaces, molds, sand casting, die casting machines | Forging presses, hydraulic hammers, dies, anvils |

| Quality Focus | Surface finish, solidification defects, dimensional accuracy | Grain structure, mechanical strength, dimensional tolerances |

| Applications | Engine blocks, pipes, valves, complex shapes | Gears, crankshafts, shafts, tools, high-strength components |

| Work Environment | Foundry setting, high heat, dust exposure | Forge shop, high heat, noise, physical exertion |

| Training & Certification | Technical diploma, foundry safety certification | Technical diploma, forging process certification |

Overview of Casting Technician Roles

Casting Technicians specialize in creating metal components by pouring molten metal into molds, ensuring precise temperature control and mold integrity for defect-free products. Their responsibilities include monitoring the casting process, inspecting raw materials, and performing quality checks to meet industry standards. Mastery of metallurgy, thermal dynamics, and safety protocols is essential for optimizing product strength and reducing production waste.

Overview of Forging Technician Roles

Forging technicians specialize in shaping metal using compressive forces, working primarily with heated metal billets to create strong, durable components for automotive, aerospace, and heavy machinery industries. Their roles include setting up forging equipment, monitoring process parameters such as temperature and pressure, and performing quality inspections to ensure the integrity and specifications of forged parts. Expertise in metallurgy, thermal processing, and equipment maintenance distinguishes forging technicians from casting technicians, who focus on molten metal pouring and solidification processes.

Key Responsibilities: Casting vs Forging Technicians

Casting Technicians specialize in designing molds, monitoring molten metal flow, and ensuring defect-free solidification during the casting process. Forging Technicians focus on controlling metal deformation through heat and pressure, maintaining die alignment, and inspecting mechanical properties for durability. Both roles require expertise in metallurgical analysis, but Casting emphasizes fluid dynamics while Forging prioritizes material shape and grain structure integrity.

Essential Skills for Casting Technicians

Casting Technicians require expertise in mold design, metal pouring techniques, and solidification process control to ensure defect-free castings. Proficiency in interpreting technical drawings, understanding material properties, and performing quality inspections is critical for maintaining casting precision and durability. Knowledge of safety protocols and equipment maintenance further enhances their effectiveness in managing casting operations.

Essential Skills for Forging Technicians

Forging Technicians require essential skills such as proficiency in metal deformation techniques, including hot and cold forging, to shape materials under controlled pressure and temperature. Expertise in interpreting technical blueprints and operating heavy forging machinery ensures precision and consistency in part fabrication. Knowledge of metallurgical properties and safety protocols is crucial to prevent defects and maintain workplace safety during high-temperature forging processes.

Tools and Equipment Used in Casting vs Forging

Casting technicians primarily use molds, melting furnaces, ladles, and gating systems to shape molten metal into desired forms, relying heavily on temperature control and mold materials such as sand or metal. Forging technicians operate hammers, presses, dies, and anvils to deform heated metal under pressure, focusing on tools that provide precise force and impact to enhance the metal's grain structure. Both roles require specialized equipment calibrated for either fluid metal handling in casting or mechanical deformation in forging to ensure product integrity and dimensional accuracy.

Training and Certification Requirements

Casting technicians typically require specialized training in mold design, metal properties, and molten metal handling, often gaining certifications such as the American Foundry Society (AFS) Certified Casting Technician. Forging technicians need in-depth knowledge of metal deformation processes, heat treatment, and die maintenance, with certifications available through organizations like the Forging Industry Association (FIA). Both roles demand hands-on experience and safety training, but casting focuses more on fluidity and solidification control, while forging emphasizes mechanical properties and material strength enhancement.

Workplace Environment and Safety Practices

Casting technicians typically work in foundries with high temperatures and molten metals, requiring strict adherence to heat-resistant protective gear and ventilation protocols to prevent inhalation of hazardous fumes. Forging technicians operate in forging shops where intense pressure and heavy machinery pose risks of crush injuries, so safety measures emphasize mechanical guards, proper ergonomics, and regular equipment maintenance. Both roles demand rigorous training in hazard recognition and compliance with OSHA standards to ensure a safe and efficient manufacturing environment.

Career Growth Opportunities

Casting technicians gain career growth opportunities through mastering mold design, metallurgy, and quality control, leading to roles like casting supervisor or process engineer. Forging technicians develop expertise in metal deformation, heat treatment, and equipment operation, enabling advancement to positions such as forging operations manager or metallurgical engineer. Both paths offer potential for specialization and leadership roles within manufacturing plants and research and development departments.

Salary Comparison and Job Outlook

Casting Technicians typically earn an average salary ranging from $45,000 to $60,000 annually, while Forging Technicians often command higher wages, averaging between $50,000 and $65,000 due to specialized skills in metal shaping processes. The job outlook for Forging Technicians is projected to grow modestly by 5% over the next decade, driven by demand in automotive and aerospace industries, whereas Casting Technicians face a steadier but slower growth rate of approximately 3%. Both roles require precision and technical expertise, but Forging Technicians benefit from broader industry applications and slightly better earning potential.

Casting Technician vs Forging Technician Infographic

jobdiv.com

jobdiv.com