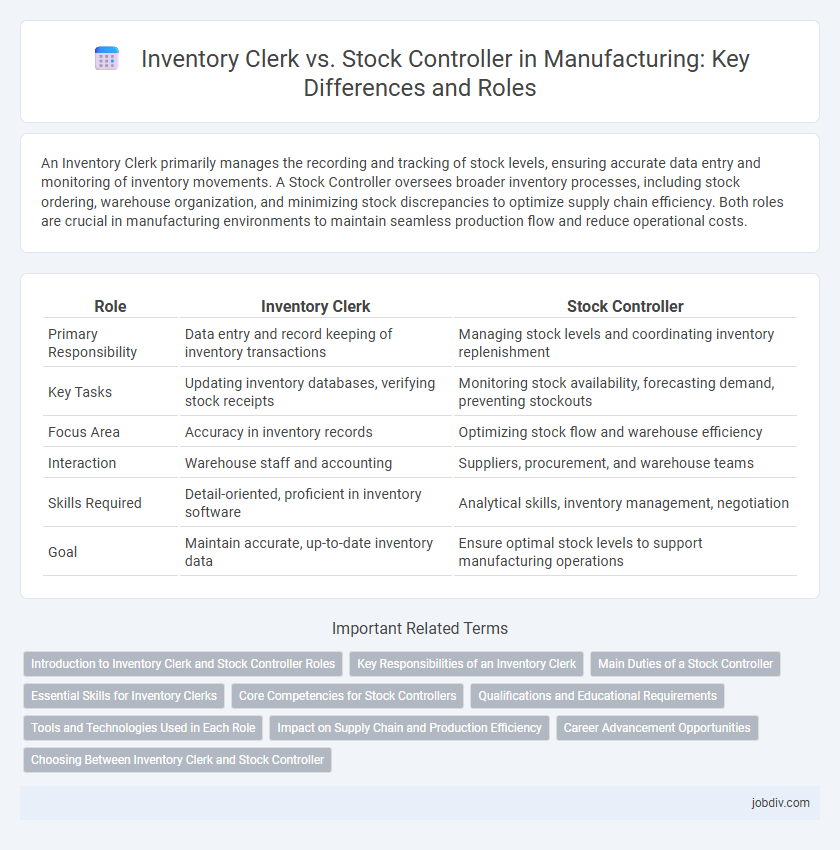

An Inventory Clerk primarily manages the recording and tracking of stock levels, ensuring accurate data entry and monitoring of inventory movements. A Stock Controller oversees broader inventory processes, including stock ordering, warehouse organization, and minimizing stock discrepancies to optimize supply chain efficiency. Both roles are crucial in manufacturing environments to maintain seamless production flow and reduce operational costs.

Table of Comparison

| Role | Inventory Clerk | Stock Controller |

|---|---|---|

| Primary Responsibility | Data entry and record keeping of inventory transactions | Managing stock levels and coordinating inventory replenishment |

| Key Tasks | Updating inventory databases, verifying stock receipts | Monitoring stock availability, forecasting demand, preventing stockouts |

| Focus Area | Accuracy in inventory records | Optimizing stock flow and warehouse efficiency |

| Interaction | Warehouse staff and accounting | Suppliers, procurement, and warehouse teams |

| Skills Required | Detail-oriented, proficient in inventory software | Analytical skills, inventory management, negotiation |

| Goal | Maintain accurate, up-to-date inventory data | Ensure optimal stock levels to support manufacturing operations |

Introduction to Inventory Clerk and Stock Controller Roles

Inventory Clerks manage daily inventory records by accurately tracking incoming and outgoing materials using inventory management software, ensuring stock levels are maintained to meet production demands. Stock Controllers oversee broader supply chain activities, including stock audits, warehouse organization, and stock replenishment strategies to optimize inventory turnover and reduce holding costs. Both roles are critical in manufacturing for maintaining efficient stock flow and supporting operational continuity.

Key Responsibilities of an Inventory Clerk

An Inventory Clerk in manufacturing manages accurate record-keeping of stock levels, processes incoming and outgoing inventory transactions, and conducts regular physical counts to ensure data integrity. They coordinate with suppliers and production teams to track material availability and prevent shortages or overstock situations. Inventory Clerks also update inventory databases and generate reports to support efficient warehouse operations and decision-making.

Main Duties of a Stock Controller

A Stock Controller in manufacturing manages inventory accuracy by monitoring stock levels, conducting regular audits, and coordinating with procurement for timely replenishment. They ensure optimal inventory turnover rates, minimize stock discrepancies, and maintain detailed records to support production schedules. By overseeing stock movement and storage, Stock Controllers play a crucial role in reducing waste and ensuring uninterrupted manufacturing operations.

Essential Skills for Inventory Clerks

Inventory clerks require strong organizational skills, attention to detail, and proficiency in inventory management software to accurately track and record stock levels. They must possess excellent communication abilities to coordinate with suppliers and warehouse teams effectively. A solid understanding of data entry and basic accounting principles ensures precise inventory documentation and reduces discrepancies in manufacturing operations.

Core Competencies for Stock Controllers

Stock Controllers excel in inventory management, demand forecasting, and supply chain coordination, ensuring accurate stock levels and minimizing discrepancies. Their expertise includes using ERP systems for real-time inventory tracking and conducting regular audits to maintain data integrity. Strong analytical skills enable Stock Controllers to optimize reorder points and reduce carrying costs, boosting overall manufacturing efficiency.

Qualifications and Educational Requirements

An Inventory Clerk typically requires a high school diploma or equivalent, with preferred qualifications including basic knowledge of inventory software and data entry skills. Stock Controllers often need more advanced qualifications such as a vocational certificate or an associate degree in supply chain management, logistics, or a related field. Proficiency in inventory management systems, analytical skills, and experience in stock control processes are essential for Stock Controllers, highlighting a higher educational and skill threshold compared to Inventory Clerks.

Tools and Technologies Used in Each Role

Inventory clerks typically utilize barcode scanners, inventory management software like SAP or Oracle, and Excel spreadsheets to track and record stock levels accurately. Stock controllers rely on advanced warehouse management systems (WMS), real-time data analytics, and RFID technology to monitor inventory flow and optimize storage efficiency. Both roles increasingly incorporate mobile devices and cloud-based platforms to streamline inventory operations and improve accuracy.

Impact on Supply Chain and Production Efficiency

An Inventory Clerk primarily manages the accuracy of inventory records through meticulous data entry and regular stock audits, directly reducing errors that disrupt production schedules. A Stock Controller strategically oversees stock levels, balancing supply and demand to prevent bottlenecks and minimize carrying costs, thereby enhancing production efficiency. Both roles are vital for maintaining a seamless supply chain, with the Inventory Clerk ensuring data integrity and the Stock Controller optimizing stock flow to support uninterrupted manufacturing operations.

Career Advancement Opportunities

Inventory Clerks typically manage day-to-day stock records and order processing, providing foundational experience crucial for career growth in manufacturing supply chain roles. Stock Controllers oversee inventory accuracy and reporting, often leading teams and driving process improvements that enhance operational efficiency and open pathways to supervisory or managerial positions. Advancing from Inventory Clerk to Stock Controller involves acquiring skills in inventory management software, data analysis, and leadership, making it a strategic step for career progression in manufacturing environments.

Choosing Between Inventory Clerk and Stock Controller

Choosing between an Inventory Clerk and a Stock Controller depends on the scale and complexity of the manufacturing operation; inventory clerks primarily focus on recording and tracking stock levels, ensuring accurate data entry and basic inventory audits. Stock controllers handle more advanced responsibilities such as analyzing stock trends, optimizing inventory turnover, and coordinating with supply chain teams to prevent overstock or shortages. Manufacturing businesses aiming for efficient inventory management and minimal production downtime often favor stock controllers for their strategic role in maintaining balanced stock levels.

Inventory Clerk vs Stock Controller Infographic

jobdiv.com

jobdiv.com