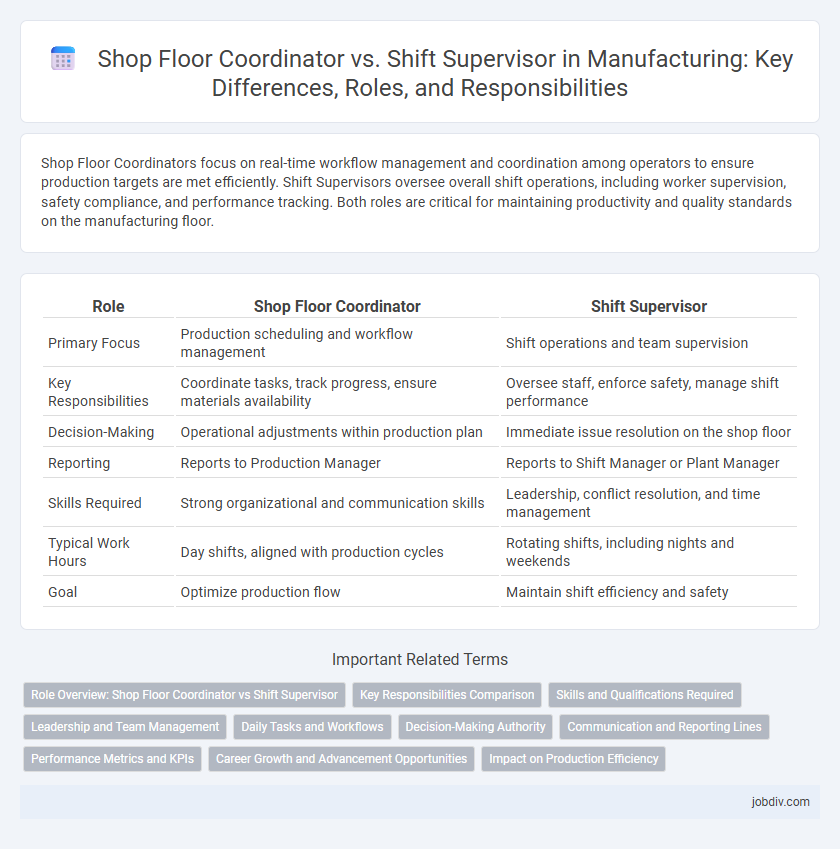

Shop Floor Coordinators focus on real-time workflow management and coordination among operators to ensure production targets are met efficiently. Shift Supervisors oversee overall shift operations, including worker supervision, safety compliance, and performance tracking. Both roles are critical for maintaining productivity and quality standards on the manufacturing floor.

Table of Comparison

| Role | Shop Floor Coordinator | Shift Supervisor |

|---|---|---|

| Primary Focus | Production scheduling and workflow management | Shift operations and team supervision |

| Key Responsibilities | Coordinate tasks, track progress, ensure materials availability | Oversee staff, enforce safety, manage shift performance |

| Decision-Making | Operational adjustments within production plan | Immediate issue resolution on the shop floor |

| Reporting | Reports to Production Manager | Reports to Shift Manager or Plant Manager |

| Skills Required | Strong organizational and communication skills | Leadership, conflict resolution, and time management |

| Typical Work Hours | Day shifts, aligned with production cycles | Rotating shifts, including nights and weekends |

| Goal | Optimize production flow | Maintain shift efficiency and safety |

Role Overview: Shop Floor Coordinator vs Shift Supervisor

A Shop Floor Coordinator manages daily production activities ensuring smooth workflow and timely issue resolution, focusing on coordination between departments and real-time problem-solving on the shop floor. In contrast, a Shift Supervisor oversees the entire shift operations, including team supervision, safety compliance, and productivity monitoring to meet shift targets. Both roles are critical for operational efficiency but differ in scope, with the coordinator emphasizing process flow and the supervisor emphasizing personnel and shift management.

Key Responsibilities Comparison

Shop Floor Coordinators manage real-time production activities to ensure workflow efficiency and address immediate operational issues, while Shift Supervisors oversee overall shift performance, including resource allocation, team supervision, and adherence to safety protocols. Coordinators focus on tracking inventory levels, equipment status, and quality checks on the shop floor, whereas Supervisors handle employee scheduling, performance evaluations, and communication between management and production staff. Both roles are critical for maintaining production continuity but differ in scope, with Coordinators operating at the operational level and Supervisors at the managerial level.

Skills and Qualifications Required

A Shop Floor Coordinator requires strong organizational skills, proficiency in production scheduling, and the ability to manage real-time workflow to ensure efficient operations. A Shift Supervisor needs leadership capabilities, experience in team management, and knowledge of safety regulations to maintain productivity and compliance during shifts. Both roles demand familiarity with manufacturing processes, quality control standards, and effective communication skills to coordinate between departments and operators.

Leadership and Team Management

Shop Floor Coordinators oversee daily workflow and coordinate tasks directly on the manufacturing line, ensuring optimal resource allocation and real-time problem-solving to maintain production efficiency. Shift Supervisors hold broader leadership responsibilities, managing entire shifts by enforcing safety protocols, overseeing team performance, and implementing operational strategies to meet production targets. Both roles require strong team management skills, but Shift Supervisors emphasize leadership in decision-making and long-term planning, while Shop Floor Coordinators focus on tactical execution and immediate team support.

Daily Tasks and Workflows

Shop Floor Coordinators manage production schedules, coordinate material flow, and ensure equipment readiness to maintain efficient operations on the manufacturing floor. Shift Supervisors oversee employee performance, enforce safety protocols, and handle issue resolution to sustain productivity during assigned shifts. Both roles require real-time problem-solving but differ as Coordinators focus on workflow optimization, while Supervisors concentrate on team management and compliance.

Decision-Making Authority

Shop Floor Coordinators primarily handle real-time problem-solving and workflow adjustments to maintain production efficiency, whereas Shift Supervisors possess broader decision-making authority encompassing personnel management, production schedules, and safety compliance. Shift Supervisors are empowered to make strategic decisions impacting operational outcomes and resource allocation, while Shop Floor Coordinators implement directives and focus on immediate process optimizations. This distinction ensures a hierarchical flow of decisions, optimizing both daily production dynamics and long-term manufacturing objectives.

Communication and Reporting Lines

Shop Floor Coordinators maintain direct communication with production teams, ensuring real-time updates and addressing operational issues promptly. Shift Supervisors oversee broader shift operations, relaying critical information between management and shop floor staff, and managing escalation reports. Clear reporting lines position Shop Floor Coordinators as facilitators within the team, while Shift Supervisors hold accountability for shift performance and coordination with higher management.

Performance Metrics and KPIs

Shop Floor Coordinators typically track real-time production metrics such as cycle time, machine uptime, and defect rates to maintain operational efficiency, while Shift Supervisors focus on broader KPIs including labor productivity, safety incidents, and shift output targets. Performance metrics for Shop Floor Coordinators emphasize immediate process optimization and quality control, whereas Shift Supervisors are evaluated on team management, adherence to production schedules, and overall shift performance. Both roles utilize data analytics tools to monitor and improve manufacturing efficiency, but the Coordinator's KPIs are more granular and task-specific compared to the Supervisor's strategic oversight metrics.

Career Growth and Advancement Opportunities

Shop Floor Coordinators primarily manage day-to-day production activities, ensuring workflow efficiency and addressing immediate operational issues, which builds foundational leadership and problem-solving skills essential for upward mobility. Shift Supervisors, overseeing entire shifts with broader responsibilities including personnel management, quality control, and liaising with upper management, typically experience faster career advancement into higher managerial roles. Both positions offer distinct pathways, but Shift Supervisors often have access to more structured leadership development programs and greater influence on strategic decisions, facilitating accelerated career growth.

Impact on Production Efficiency

Shop floor coordinators streamline daily operations by managing task assignments and ensuring resource availability, directly reducing downtime and bottlenecks on the manufacturing line. Shift supervisors oversee workforce performance and enforce quality standards, driving consistent output and minimizing errors during production cycles. Both roles are essential for optimizing production efficiency, with coordinators focusing on workflow coordination and supervisors emphasizing personnel management.

Shop Floor Coordinator vs Shift Supervisor Infographic

jobdiv.com

jobdiv.com