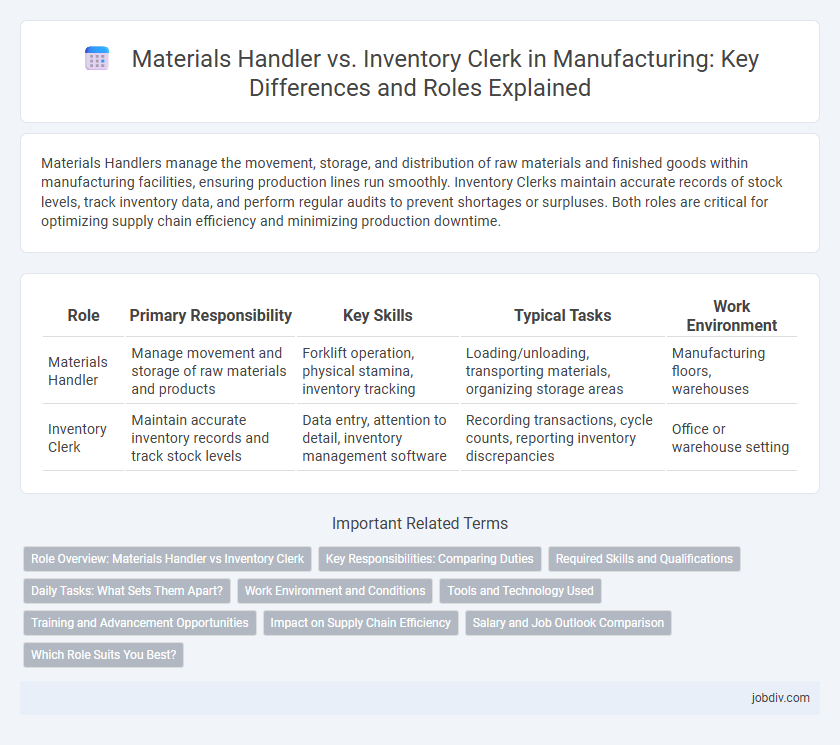

Materials Handlers manage the movement, storage, and distribution of raw materials and finished goods within manufacturing facilities, ensuring production lines run smoothly. Inventory Clerks maintain accurate records of stock levels, track inventory data, and perform regular audits to prevent shortages or surpluses. Both roles are critical for optimizing supply chain efficiency and minimizing production downtime.

Table of Comparison

| Role | Primary Responsibility | Key Skills | Typical Tasks | Work Environment |

|---|---|---|---|---|

| Materials Handler | Manage movement and storage of raw materials and products | Forklift operation, physical stamina, inventory tracking | Loading/unloading, transporting materials, organizing storage areas | Manufacturing floors, warehouses |

| Inventory Clerk | Maintain accurate inventory records and track stock levels | Data entry, attention to detail, inventory management software | Recording transactions, cycle counts, reporting inventory discrepancies | Office or warehouse setting |

Role Overview: Materials Handler vs Inventory Clerk

Materials Handlers in manufacturing manage the physical movement, storage, and distribution of raw materials and finished products, ensuring timely delivery to production lines. Inventory Clerks focus on tracking and documenting inventory levels, performing cycle counts, and maintaining accurate records to prevent stock discrepancies. Both roles are essential for seamless production flow and inventory accuracy but differ in hands-on material management versus administrative inventory control.

Key Responsibilities: Comparing Duties

Materials Handlers are responsible for moving, storing, and distributing raw materials and finished goods within the manufacturing facility, ensuring timely supply to production lines and maintaining safe material handling practices. Inventory Clerks focus on tracking inventory levels, conducting regular stock audits, updating records in inventory management systems, and coordinating with purchasing and production departments to prevent shortages or overstocking. Both roles are crucial for efficient manufacturing operations, with Materials Handlers emphasizing physical logistics and Inventory Clerks concentrating on data accuracy and inventory control.

Required Skills and Qualifications

Materials Handlers require physical strength, attention to detail, and proficiency in using forklifts and warehouse management systems, along with knowledge of safety regulations and inventory control. Inventory Clerks must possess strong organizational skills, data entry accuracy, and familiarity with inventory software and auditing processes to manage stock levels and documentation effectively. Both roles benefit from experience in logistics and supply chain operations, with Inventory Clerks emphasizing analytical skills for tracking inventory trends.

Daily Tasks: What Sets Them Apart?

Materials Handlers manage the physical flow of raw materials and finished goods by receiving, moving, and storing inventory within manufacturing facilities, ensuring accurate labeling and timely delivery to production lines. Inventory Clerks focus on tracking and documenting stock levels using inventory management software, reconciling discrepancies, and preparing reports to maintain accurate inventory records. The key difference lies in Materials Handlers' hands-on movement of goods versus Inventory Clerks' responsibility for data accuracy and inventory control documentation.

Work Environment and Conditions

Materials Handlers typically work in physically demanding environments such as warehouses, factories, and shipping areas where heavy lifting, operating forklifts, and exposure to varying temperatures are common conditions. Inventory Clerks usually perform their duties indoors within office or warehouse settings, involving tasks like data entry and inventory tracking, which require less physical labor but demand attention to detail and prolonged use of computers. Both roles require adherence to safety protocols, but Materials Handlers face more hazardous conditions due to the nature of handling raw materials and equipment.

Tools and Technology Used

Materials Handlers primarily utilize forklifts, pallet jacks, barcode scanners, and warehouse management systems (WMS) to move and track physical inventory efficiently. Inventory Clerks rely on inventory management software, ERP (Enterprise Resource Planning) systems, handheld scanners, and spreadsheets to monitor stock levels and update records accurately. Both roles leverage technology to enhance accuracy, speed, and organization within manufacturing supply chains.

Training and Advancement Opportunities

Materials handlers typically receive on-the-job training focused on equipment operation and safety protocols, enabling quick skill acquisition for handling raw materials and products. Inventory clerks often require formal training in inventory management software and data accuracy, supporting career growth into supply chain or logistics roles. Advancement opportunities for materials handlers frequently lead to supervisory or equipment specialist positions, while inventory clerks can progress toward inventory control management or procurement analyst roles.

Impact on Supply Chain Efficiency

Materials Handlers play a critical role in supply chain efficiency by ensuring timely movement and proper storage of raw materials and finished goods, reducing delays in production. Inventory Clerks maintain accurate records of stock levels and coordinate inventory replenishment, preventing stockouts and excess inventory. Together, their functions optimize material flow and inventory accuracy, directly enhancing manufacturing throughput and reducing operational costs.

Salary and Job Outlook Comparison

Materials handlers in manufacturing earn an average annual salary of $34,000, with job growth projected at 5% over the next decade. Inventory clerks typically make slightly more, averaging $37,000 per year, supported by a steady demand growth rate of 6%. Both roles require attention to detail and organization, but inventory clerks benefit from stronger market demand and higher pay.

Which Role Suits You Best?

Materials Handlers specialize in moving and organizing raw materials and finished products within manufacturing facilities, requiring physical strength and equipment operation skills. Inventory Clerks focus on tracking stock levels, recording transactions, and ensuring accurate inventory data using software systems, emphasizing attention to detail and analytical abilities. Choosing the right role depends on whether you prefer hands-on logistics and equipment handling or managing data accuracy and inventory control in a manufacturing environment.

Materials Handler vs Inventory Clerk Infographic

jobdiv.com

jobdiv.com