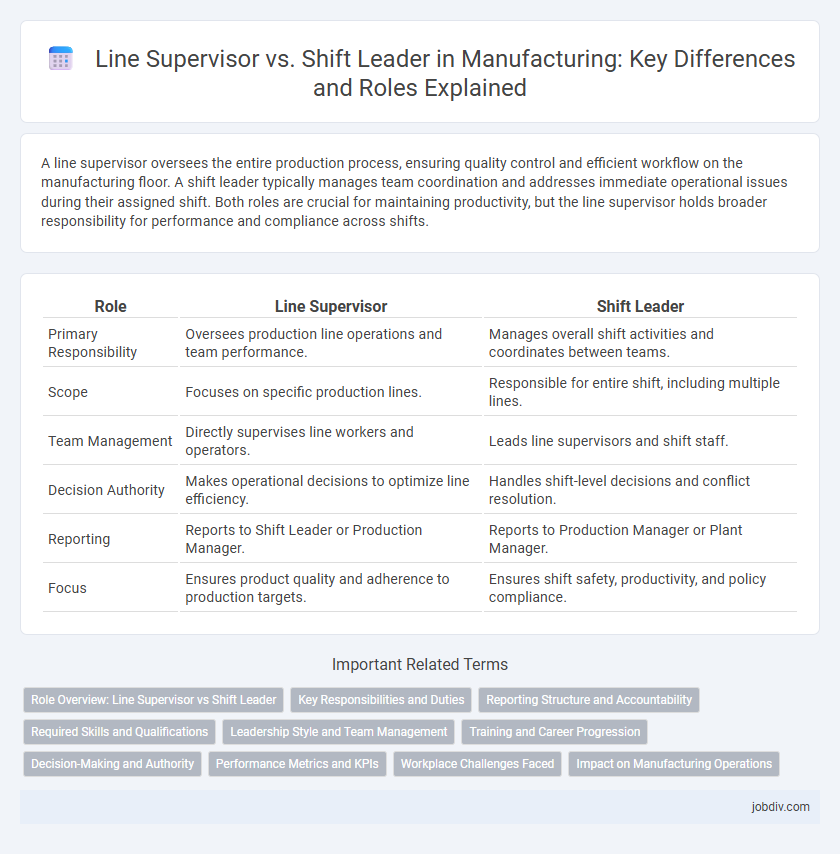

A line supervisor oversees the entire production process, ensuring quality control and efficient workflow on the manufacturing floor. A shift leader typically manages team coordination and addresses immediate operational issues during their assigned shift. Both roles are crucial for maintaining productivity, but the line supervisor holds broader responsibility for performance and compliance across shifts.

Table of Comparison

| Role | Line Supervisor | Shift Leader |

|---|---|---|

| Primary Responsibility | Oversees production line operations and team performance. | Manages overall shift activities and coordinates between teams. |

| Scope | Focuses on specific production lines. | Responsible for entire shift, including multiple lines. |

| Team Management | Directly supervises line workers and operators. | Leads line supervisors and shift staff. |

| Decision Authority | Makes operational decisions to optimize line efficiency. | Handles shift-level decisions and conflict resolution. |

| Reporting | Reports to Shift Leader or Production Manager. | Reports to Production Manager or Plant Manager. |

| Focus | Ensures product quality and adherence to production targets. | Ensures shift safety, productivity, and policy compliance. |

Role Overview: Line Supervisor vs Shift Leader

Line Supervisors manage specific production lines, ensuring efficient workflow, quality control, and adherence to safety standards. Shift Leaders oversee entire shifts, coordinating various teams, managing schedules, and addressing operational issues to maintain continuous production. Both roles require strong leadership, but Line Supervisors focus more on direct process supervision while Shift Leaders emphasize broader shift coordination and problem-solving.

Key Responsibilities and Duties

Line Supervisors oversee production lines ensuring workflow efficiency, quality control, and adherence to safety standards. Shift Leaders manage workforce coordination, monitor shift progress, and address operational issues in real-time to maintain production targets. Both roles require strong communication skills and leadership to optimize manufacturing output and ensure compliance with organizational policies.

Reporting Structure and Accountability

Line Supervisors report directly to production managers and are accountable for meeting specific output targets and quality standards on the manufacturing floor. Shift Leaders report to Line Supervisors and oversee real-time operations, ensuring team adherence to schedules and safety protocols. Accountability for Line Supervisors encompasses broader productivity goals, while Shift Leaders focus on immediate operational issues and workforce coordination during their shifts.

Required Skills and Qualifications

Line Supervisors require expertise in production processes, quality control, and staff management, often holding a technical diploma or relevant manufacturing certification. Shift Leaders emphasize leadership skills, shift scheduling, and real-time problem-solving, typically needing proven experience in team coordination and operational oversight. Both roles demand strong communication abilities, safety compliance knowledge, and proficiency in workflow optimization within manufacturing environments.

Leadership Style and Team Management

Line Supervisors emphasize structured leadership with direct oversight on production processes, ensuring strict adherence to standards and efficient workflow. Shift Leaders adopt a more adaptive leadership style, focusing on real-time problem-solving and fostering team collaboration during their shifts. Both roles require strong communication skills, but Shift Leaders prioritize immediate decision-making while Line Supervisors emphasize long-term team development and performance monitoring.

Training and Career Progression

Line Supervisors typically undergo comprehensive training programs focused on production efficiency, quality control, and team management to advance into higher managerial roles. Shift Leaders receive targeted on-the-job training that emphasizes real-time problem solving, team coordination, and operational oversight, preparing them for supervisory positions. Career progression for Line Supervisors often leads to departments such as operations management or manufacturing engineering, whereas Shift Leaders frequently transition into Line Supervisor roles after acquiring leadership experience.

Decision-Making and Authority

Line supervisors hold formal authority over production teams, enabling them to make critical decisions related to workflow, quality control, and resource allocation. Shift leaders often possess operational decision-making power but typically act under the guidance of line supervisors, focusing on real-time issue resolution and team coordination. The distinction in authority impacts manufacturing efficiency, with line supervisors responsible for strategic oversight and shift leaders ensuring tactical execution.

Performance Metrics and KPIs

Line Supervisors primarily focus on production output, quality control, and adherence to safety standards, using KPIs such as units produced per hour, defect rates, and incident frequency to evaluate performance. Shift Leaders emphasize workforce management and operational efficiency, tracking metrics like labor utilization, downtime reduction, and employee attendance to optimize shift productivity. Both roles rely on real-time data analysis and continuous feedback loops to improve manufacturing processes and meet organizational goals.

Workplace Challenges Faced

Line Supervisors often grapple with maintaining production efficiency while managing diverse team skill levels and ensuring strict adherence to safety protocols. Shift Leaders face challenges in coordinating seamless shift transitions and resolving real-time operational issues that affect workflow continuity. Both roles demand strong conflict resolution skills to address employee disputes and mitigate downtime in fast-paced manufacturing environments.

Impact on Manufacturing Operations

Line supervisors ensure production efficiency by managing workflow, quality control, and employee performance on the manufacturing floor. Shift leaders focus on coordinating team activities during shifts, addressing immediate operational issues and maintaining safety standards. Both roles directly influence manufacturing output, but line supervisors typically have broader authority over process improvements and day-to-day production management.

Line Supervisor vs Shift Leader Infographic

jobdiv.com

jobdiv.com