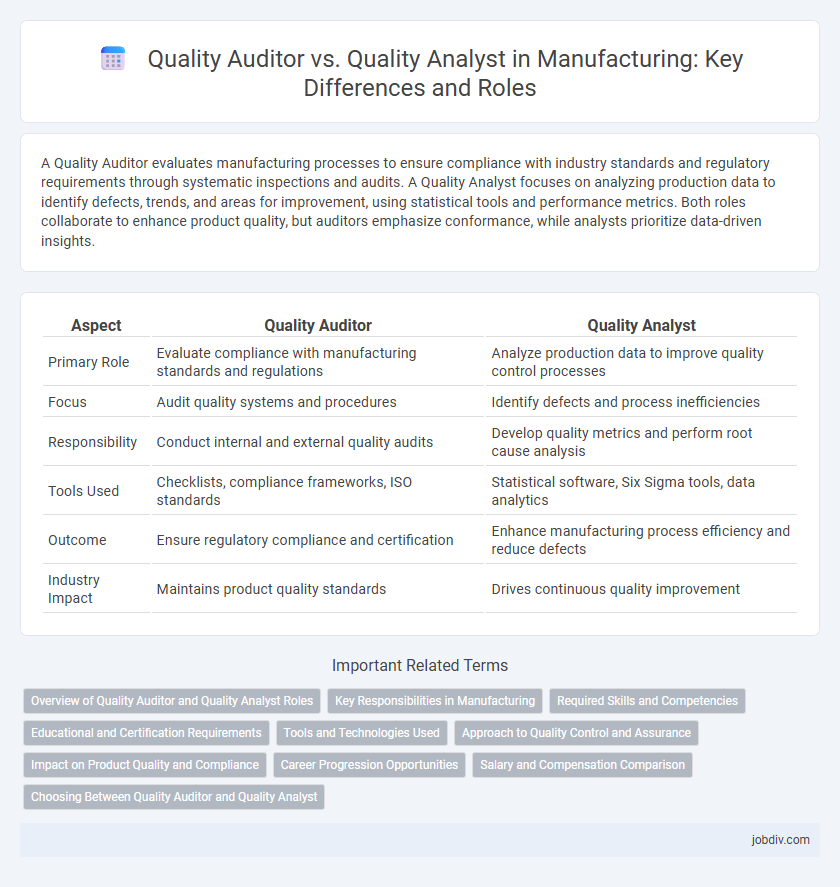

A Quality Auditor evaluates manufacturing processes to ensure compliance with industry standards and regulatory requirements through systematic inspections and audits. A Quality Analyst focuses on analyzing production data to identify defects, trends, and areas for improvement, using statistical tools and performance metrics. Both roles collaborate to enhance product quality, but auditors emphasize conformance, while analysts prioritize data-driven insights.

Table of Comparison

| Aspect | Quality Auditor | Quality Analyst |

|---|---|---|

| Primary Role | Evaluate compliance with manufacturing standards and regulations | Analyze production data to improve quality control processes |

| Focus | Audit quality systems and procedures | Identify defects and process inefficiencies |

| Responsibility | Conduct internal and external quality audits | Develop quality metrics and perform root cause analysis |

| Tools Used | Checklists, compliance frameworks, ISO standards | Statistical software, Six Sigma tools, data analytics |

| Outcome | Ensure regulatory compliance and certification | Enhance manufacturing process efficiency and reduce defects |

| Industry Impact | Maintains product quality standards | Drives continuous quality improvement |

Overview of Quality Auditor and Quality Analyst Roles

Quality Auditors systematically evaluate manufacturing processes and product quality to ensure compliance with industry standards and regulatory requirements, identifying areas for corrective actions. Quality Analysts analyze data trends from production metrics to optimize product consistency, enhance process efficiency, and support continuous improvement initiatives. Both roles collaborate to maintain product integrity and uphold quality management systems within manufacturing operations.

Key Responsibilities in Manufacturing

Quality Auditors in manufacturing primarily focus on inspecting and verifying compliance with industry standards, conducting regular audits, and ensuring that production processes meet quality requirements. Quality Analysts analyze data trends from production outputs, identify defects or deviations, and recommend improvements to optimize product quality and operational efficiency. Both roles are crucial for maintaining high-quality standards and continuous improvement in manufacturing environments.

Required Skills and Competencies

Quality Auditors require strong expertise in compliance standards, attention to detail, and proficiency in conducting systematic inspections to ensure manufacturing processes meet regulatory and internal quality requirements. Quality Analysts focus on data analysis, problem-solving skills, and knowledge of statistical tools to interpret process performance and implement continuous improvement strategies. Both roles demand effective communication and thorough knowledge of quality management systems such as ISO 9001 but differ in their primary skill emphasis: auditing versus analytical evaluation.

Educational and Certification Requirements

Quality Auditors in manufacturing typically require a background in industrial engineering or quality management, often holding certifications such as ASQ Certified Quality Auditor (CQA) or ISO 9001 Lead Auditor. Quality Analysts usually possess degrees in statistics, data science, or engineering, with certifications like Six Sigma Green Belt or Certified Quality Improvement Associate (CQIA) enhancing their expertise. Both roles benefit from understanding ISO standards and statistical process control (SPC) methodologies to ensure manufacturing process optimization and compliance.

Tools and Technologies Used

Quality Auditors primarily utilize audit management software, statistical process control (SPC) tools, and compliance tracking systems to evaluate manufacturing processes and ensure adherence to regulatory standards. Quality Analysts focus on data analysis software, such as Six Sigma tools, Minitab, and advanced Excel functions, to identify process inefficiencies and drive continuous improvement. Both roles often employ enterprise resource planning (ERP) systems and quality management systems (QMS) to streamline quality control workflows and enhance data accuracy.

Approach to Quality Control and Assurance

Quality Auditors systematically evaluate compliance with established manufacturing standards through independent inspections and documentation reviews, ensuring adherence to regulatory requirements and internal procedures. Quality Analysts focus on data-driven analysis to identify process inefficiencies, trends, and defects, implementing improvements to enhance product quality and reduce variability. Both roles collectively strengthen quality control and assurance by combining verification with continuous process optimization.

Impact on Product Quality and Compliance

Quality Auditors systematically assess manufacturing processes to ensure strict adherence to regulatory standards and internal quality protocols, directly minimizing risks of non-compliance and product defects. Quality Analysts analyze process data and product metrics to identify trends and root causes of quality issues, enabling targeted improvements that enhance product reliability and performance. Both roles drive continuous quality enhancement, but auditors focus on compliance enforcement while analysts emphasize data-driven process optimization.

Career Progression Opportunities

Quality Auditors in manufacturing primarily focus on compliance and process adherence, building a strong foundation for roles in regulatory affairs or quality assurance management. Quality Analysts analyze data trends and identify areas for process improvement, creating pathways toward roles in continuous improvement or operations management. Both career paths offer advancement opportunities, with auditors often moving into audit management and analysts progressing into strategic quality leadership positions.

Salary and Compensation Comparison

Quality Auditors in manufacturing typically earn an average salary ranging from $55,000 to $75,000 annually, reflecting their role in ensuring compliance with industry standards and conducting systematic inspections. Quality Analysts often receive slightly higher compensation, averaging between $60,000 and $80,000 per year, due to their focus on data analysis, process improvements, and quality control strategies that drive operational efficiency. Salary variations depend on experience, certifications, and geographic location, with Quality Analysts generally benefiting from performance bonuses linked to production metrics.

Choosing Between Quality Auditor and Quality Analyst

Choosing between a Quality Auditor and a Quality Analyst hinges on the organization's focus: Quality Auditors specialize in ensuring compliance with industry standards and regulatory requirements through systematic inspections and audits, while Quality Analysts emphasize data-driven process improvements and product quality assessments. In manufacturing, a Quality Auditor is essential for certifications like ISO 9001, providing critical oversight and risk mitigation. Conversely, a Quality Analyst utilizes statistical tools and root cause analysis to optimize production efficiency and reduce defects.

Quality Auditor vs Quality Analyst Infographic

jobdiv.com

jobdiv.com