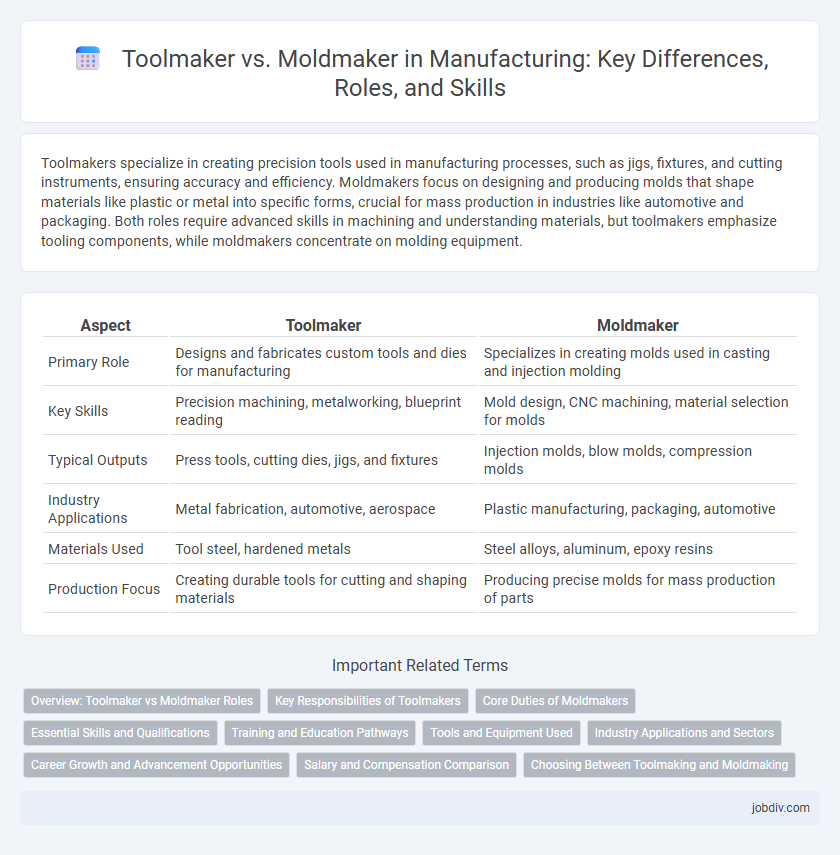

Toolmakers specialize in creating precision tools used in manufacturing processes, such as jigs, fixtures, and cutting instruments, ensuring accuracy and efficiency. Moldmakers focus on designing and producing molds that shape materials like plastic or metal into specific forms, crucial for mass production in industries like automotive and packaging. Both roles require advanced skills in machining and understanding materials, but toolmakers emphasize tooling components, while moldmakers concentrate on molding equipment.

Table of Comparison

| Aspect | Toolmaker | Moldmaker |

|---|---|---|

| Primary Role | Designs and fabricates custom tools and dies for manufacturing | Specializes in creating molds used in casting and injection molding |

| Key Skills | Precision machining, metalworking, blueprint reading | Mold design, CNC machining, material selection for molds |

| Typical Outputs | Press tools, cutting dies, jigs, and fixtures | Injection molds, blow molds, compression molds |

| Industry Applications | Metal fabrication, automotive, aerospace | Plastic manufacturing, packaging, automotive |

| Materials Used | Tool steel, hardened metals | Steel alloys, aluminum, epoxy resins |

| Production Focus | Creating durable tools for cutting and shaping materials | Producing precise molds for mass production of parts |

Overview: Toolmaker vs Moldmaker Roles

Toolmakers specialize in creating precision tools and dies used in manufacturing processes, ensuring parts and components meet exact specifications. Moldmakers focus on designing and fabricating molds for plastic injection molding, enabling mass production of plastic parts with consistent quality. Both roles require advanced skills in machining, metallurgy, and CAD/CAM software, but toolmakers emphasize tool durability while moldmakers prioritize mold accuracy and surface finish.

Key Responsibilities of Toolmakers

Toolmakers specialize in designing, constructing, and maintaining precision tools and dies essential for manufacturing processes. They interpret blueprints to create jigs, fixtures, and cutting tools that ensure accurate production and high-quality output. Their expertise directly supports machining operations, enabling efficient assembly and consistent product standards.

Core Duties of Moldmakers

Moldmakers specialize in designing, fabricating, and maintaining molds used for shaping materials such as plastics, metals, and composites in manufacturing processes. They interpret engineering drawings, select appropriate materials, and use precision tools and machinery to create molds that meet exact specifications. Their core duties include ensuring mold accuracy, performing regular inspections, and troubleshooting mold performance to optimize production efficiency and quality.

Essential Skills and Qualifications

Toolmakers require advanced machining skills, precision metalworking, and proficiency in reading complex technical drawings to create custom tools and dies. Moldmakers specialize in injection mold design, steel fabrication, and knowledge of plastics processing, emphasizing the ability to produce high-precision molds for manufacturing. Both roles demand expertise in CNC programming and quality control to ensure accuracy and functionality in production tools.

Training and Education Pathways

Toolmakers generally pursue comprehensive technical education in precision machining, often completing apprenticeships that emphasize CNC programming, blueprint reading, and metal fabrication. Moldmakers require specialized training focused on mold design, material properties, and injection molding processes, frequently obtained through vocational schools or targeted certificate programs. Both professions demand strong mathematical skills and hands-on experience, but moldmakers typically engage more intensively with polymer science and molding technology courses.

Tools and Equipment Used

Toolmakers primarily use precision measuring instruments, CNC machines, and grinding tools to fabricate custom tools, dies, and gauges for manufacturing processes. Moldmakers specialize in high-precision milling machines, EDM (Electrical Discharge Machines), and polishing equipment to create detailed molds for plastic injection molding and casting. Both professions rely heavily on CAD/CAM software for design and simulation, ensuring accuracy in tool and mold production.

Industry Applications and Sectors

Toolmakers specialize in producing precision tools used in machining and assembly processes across automotive, aerospace, and electronics industries. Moldmakers focus on creating molds for plastic injection, metal casting, and rubber molding, primarily serving packaging, consumer goods, and medical device sectors. Both professions are critical in manufacturing for developing customized components that meet industry-specific quality and performance standards.

Career Growth and Advancement Opportunities

Toolmakers typically experience steady career growth through gaining expertise in precision machining and working with various metalworking tools, leading to roles such as senior toolmaker or manufacturing supervisor. Moldmakers often have accelerated advancement opportunities by specializing in plastic injection molds and complex mold designs, allowing transitions into mold design engineering or project management roles. Both careers offer pathways to leadership positions, but moldmakers may access quicker advancement in industries focused on molded products and automation technology.

Salary and Compensation Comparison

Toolmakers typically earn an average salary ranging from $50,000 to $70,000 annually, while moldmakers often command slightly higher compensation between $55,000 and $75,000 due to specialized skills in mold fabrication. Salary variations depend on factors such as industry, geographic location, and years of experience, with moldmakers in high-demand sectors or regions like the automotive industry or the Midwest earning top-tier wages. Benefits packages for both roles commonly include health insurance, retirement plans, and performance bonuses, but moldmakers may receive additional incentives tied to the complexity and precision required in mold production.

Choosing Between Toolmaking and Moldmaking

Choosing between toolmaking and moldmaking depends on the specific manufacturing requirements, with toolmaking focusing on creating precision tools for metal shaping and assembly, while moldmaking centers on producing molds for plastic injection or casting processes. Toolmakers specialize in fabricating jigs, dies, and cutting tools, essential for stamping and machining operations, whereas moldmakers develop complex cavity molds that dictate the final shape and surface finish of molded parts. Understanding production volume, material type, and product design intricacies is crucial for selecting the appropriate manufacturing path.

Toolmaker vs Moldmaker Infographic

jobdiv.com

jobdiv.com