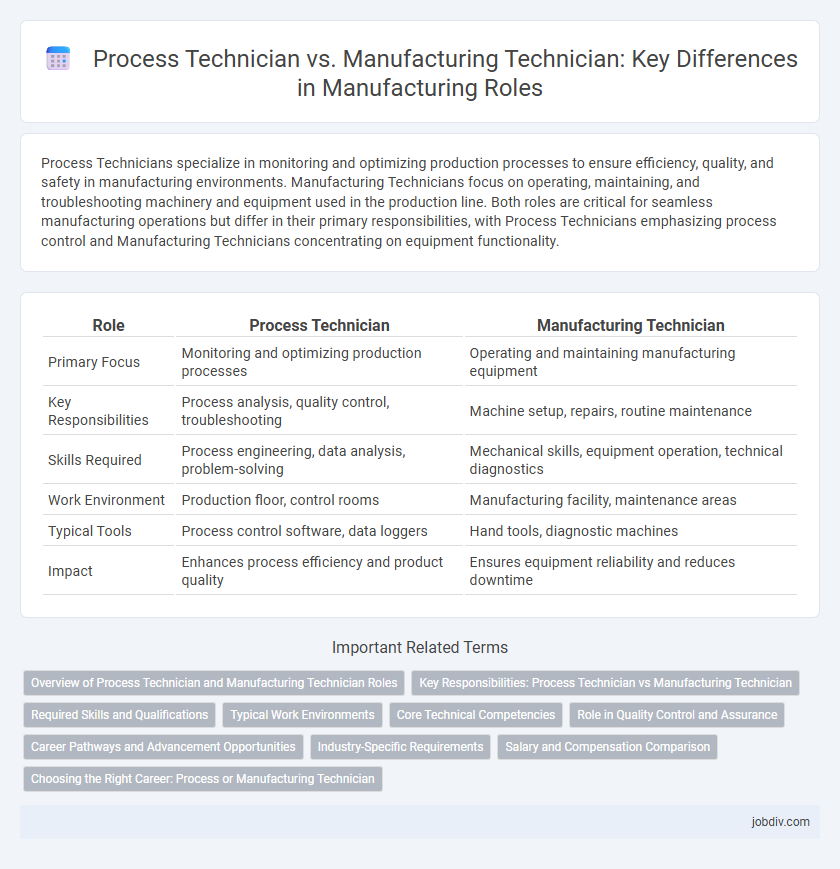

Process Technicians specialize in monitoring and optimizing production processes to ensure efficiency, quality, and safety in manufacturing environments. Manufacturing Technicians focus on operating, maintaining, and troubleshooting machinery and equipment used in the production line. Both roles are critical for seamless manufacturing operations but differ in their primary responsibilities, with Process Technicians emphasizing process control and Manufacturing Technicians concentrating on equipment functionality.

Table of Comparison

| Role | Process Technician | Manufacturing Technician |

|---|---|---|

| Primary Focus | Monitoring and optimizing production processes | Operating and maintaining manufacturing equipment |

| Key Responsibilities | Process analysis, quality control, troubleshooting | Machine setup, repairs, routine maintenance |

| Skills Required | Process engineering, data analysis, problem-solving | Mechanical skills, equipment operation, technical diagnostics |

| Work Environment | Production floor, control rooms | Manufacturing facility, maintenance areas |

| Typical Tools | Process control software, data loggers | Hand tools, diagnostic machines |

| Impact | Enhances process efficiency and product quality | Ensures equipment reliability and reduces downtime |

Overview of Process Technician and Manufacturing Technician Roles

Process Technicians specialize in monitoring and optimizing production processes, ensuring equipment operates within specified parameters to maintain product quality and efficiency. Manufacturing Technicians focus on assembling, testing, and maintaining machinery and products during the manufacturing cycle, emphasizing hands-on technical skills to support production lines. Both roles require strong problem-solving abilities and adherence to safety standards but differ in scope, with Process Technicians concentrating on process control and Manufacturing Technicians on operational execution.

Key Responsibilities: Process Technician vs Manufacturing Technician

Process Technicians specialize in monitoring and optimizing production processes, ensuring equipment functions efficiently and product quality meets standards. Manufacturing Technicians focus on assembling, testing, and maintaining manufacturing systems to support smooth production operations. Both roles require detailed knowledge of production workflows, but Process Technicians emphasize process improvement while Manufacturing Technicians concentrate on hands-on equipment management.

Required Skills and Qualifications

Process Technicians require expertise in process control, quality assurance, and troubleshooting production issues, often holding certifications in Six Sigma or Lean Manufacturing. Manufacturing Technicians need strong mechanical skills, knowledge of assembly line operations, and proficiency with CNC machinery, typically accompanied by a technical diploma or associate degree in manufacturing technology. Both roles demand attention to detail, safety compliance, and the ability to interpret technical drawings and standard operating procedures.

Typical Work Environments

Process Technicians typically work in controlled environments such as chemical plants, pharmaceuticals, and food production facilities where monitoring and optimizing manufacturing processes is crucial. Manufacturing Technicians are often found on factory floors, assembly lines, and machinery-heavy plants focusing on equipment maintenance, production support, and quality assurance. Both roles require familiarity with industry standards like GMP (Good Manufacturing Practices) and lean manufacturing but differ in their proximity to process control versus hands-on production tasks.

Core Technical Competencies

Process Technicians specialize in optimizing production workflows, with core competencies in quality control, process monitoring, and equipment calibration to ensure consistent product output. Manufacturing Technicians focus on maintaining and troubleshooting manufacturing equipment, possessing expertise in mechanical systems, electrical diagnostics, and preventative maintenance. Both roles require strong problem-solving skills and an understanding of safety protocols, but Process Technicians emphasize process efficiency, while Manufacturing Technicians prioritize equipment reliability.

Role in Quality Control and Assurance

Process Technicians focus on monitoring and optimizing production processes to ensure consistent quality standards are met, using data analysis and process adjustments to prevent defects. Manufacturing Technicians are responsible for inspecting finished products, conducting quality tests, and ensuring compliance with company specifications and regulatory requirements. Both roles play critical parts in quality control and assurance by collaborating to identify issues early and maintain high product standards throughout the manufacturing cycle.

Career Pathways and Advancement Opportunities

Process Technicians specialize in monitoring and optimizing production processes, often advancing into roles like Process Engineer or Quality Assurance Manager by gaining expertise in process improvement and automation. Manufacturing Technicians focus on equipment maintenance and assembly line support, paving the way toward roles such as Maintenance Supervisor or Production Manager through skills in machinery troubleshooting and operational efficiency. Both career pathways offer progression through certifications, hands-on experience, and leadership opportunities within manufacturing plants and industrial settings.

Industry-Specific Requirements

Process Technicians specialize in monitoring and optimizing chemical reactions, equipment, and process parameters critical to industries such as pharmaceuticals, petrochemicals, and food processing. Manufacturing Technicians focus on assembly line operations, machinery maintenance, and quality control in sectors like automotive, electronics, and consumer goods production. Industry-specific requirements for Process Technicians include knowledge of process control systems and safety protocols, whereas Manufacturing Technicians must excel in mechanical troubleshooting and lean manufacturing principles.

Salary and Compensation Comparison

Process Technicians typically earn an average salary ranging from $50,000 to $65,000 annually, with variations based on industry and experience. Manufacturing Technicians often receive a similar compensation package but may have a slightly higher median salary around $55,000 to $70,000 due to broader technical responsibilities. Both roles can include additional benefits such as bonuses, overtime pay, and health insurance, which significantly impact overall compensation.

Choosing the Right Career: Process or Manufacturing Technician

Process Technicians specialize in monitoring and optimizing production processes using advanced control systems to ensure product quality and efficiency. Manufacturing Technicians focus on equipment maintenance, troubleshooting, and assembly line support to maintain continuous production flow. Choosing the right career depends on whether you prefer data-driven process management or hands-on technical problem-solving in a manufacturing environment.

Process Technician vs Manufacturing Technician Infographic

jobdiv.com

jobdiv.com