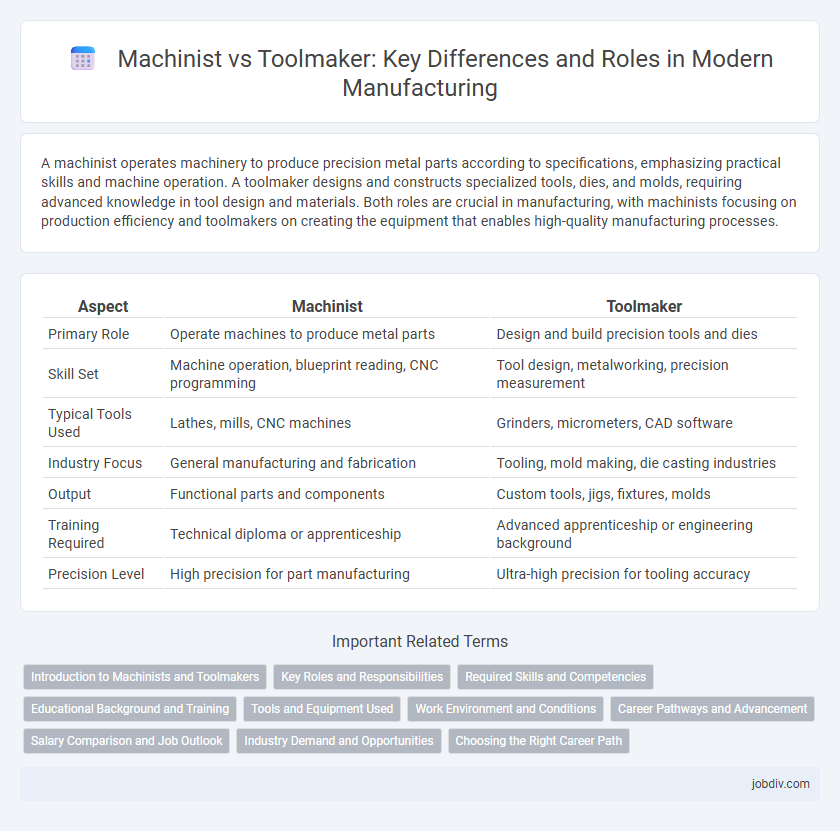

A machinist operates machinery to produce precision metal parts according to specifications, emphasizing practical skills and machine operation. A toolmaker designs and constructs specialized tools, dies, and molds, requiring advanced knowledge in tool design and materials. Both roles are crucial in manufacturing, with machinists focusing on production efficiency and toolmakers on creating the equipment that enables high-quality manufacturing processes.

Table of Comparison

| Aspect | Machinist | Toolmaker |

|---|---|---|

| Primary Role | Operate machines to produce metal parts | Design and build precision tools and dies |

| Skill Set | Machine operation, blueprint reading, CNC programming | Tool design, metalworking, precision measurement |

| Typical Tools Used | Lathes, mills, CNC machines | Grinders, micrometers, CAD software |

| Industry Focus | General manufacturing and fabrication | Tooling, mold making, die casting industries |

| Output | Functional parts and components | Custom tools, jigs, fixtures, molds |

| Training Required | Technical diploma or apprenticeship | Advanced apprenticeship or engineering background |

| Precision Level | High precision for part manufacturing | Ultra-high precision for tooling accuracy |

Introduction to Machinists and Toolmakers

Machinists specialize in operating machine tools to create precision metal parts, employing skills in milling, turning, and grinding to meet specific engineering specifications. Toolmakers focus on designing, constructing, and repairing precision tools, dies, and molds, ensuring high accuracy in production processes. Both roles require expertise in blueprint reading, measurement instruments, and adherence to strict quality standards within manufacturing environments.

Key Roles and Responsibilities

Machinists primarily operate machine tools such as lathes, mills, and grinders to fabricate precision metal parts according to blueprints and specifications. Toolmakers specialize in designing, building, and maintaining the dies, molds, fixtures, and specialized tools used in manufacturing processes. Both roles require expertise in interpreting technical drawings and ensuring tight tolerances, but toolmakers focus more on custom tool fabrication while machinists concentrate on part production.

Required Skills and Competencies

Machinists require strong technical skills in operating machine tools, precise measurement techniques, and reading blueprints to produce parts with high accuracy. Toolmakers demand advanced competencies in designing, fabricating, and maintaining specialized tools, alongside expertise in metallurgy and computer numerical control (CNC) programming. Both roles necessitate problem-solving abilities, attention to detail, and proficiency in using precision instruments, but toolmakers typically require deeper analytical skills for tool development.

Educational Background and Training

Machinists typically complete technical diplomas or apprenticeships focusing on operating machine tools with precision, while toolmakers undergo more extensive education including advanced apprenticeships and often pursue certifications in tool and die making. Toolmakers acquire specialized training in designing, building, and maintaining precision tools and molds, requiring in-depth knowledge of metallurgy and CAD/CAM software. Machinists focus primarily on the setup and operation of machinery to produce parts based on engineered specifications, emphasizing hands-on skills and mechanical aptitude.

Tools and Equipment Used

Machinists primarily use lathes, milling machines, grinders, and CNC machines to shape metal and other materials into precise parts. Toolmakers utilize similar equipment but often work with specialized jigs, dies, molds, and precision measuring instruments to create and repair tools for manufacturing processes. Both roles rely heavily on accurate blueprints and advanced machinery to ensure high-quality production and maintain tight tolerances.

Work Environment and Conditions

Machinists typically work in manufacturing plants, machine shops, or industrial facilities, often operating CNC machines, lathes, and milling machines under loud and sometimes hazardous conditions that require safety gear. Toolmakers frequently work in similar industrial settings but may spend more time in precision-focused tool rooms where maintaining clean and controlled environments is necessary to ensure exact measurements. Both roles demand standing for long periods and adherence to strict safety protocols due to exposure to sharp tools, heavy machinery, and potential metal shavings or dust.

Career Pathways and Advancement

Machinists typically begin with hands-on training in machine operation and progress to specialized roles such as CNC programmer or production supervisor, emphasizing practical skills and precision manufacturing. Toolmakers advance through apprenticeships that combine machining expertise with design proficiency, often leading to roles in tool design engineering or manufacturing management. Both career pathways offer advancement through continuous skill development, certification, and leadership opportunities within manufacturing environments.

Salary Comparison and Job Outlook

Machinists earn an average salary ranging from $40,000 to $55,000 annually, while toolmakers typically command higher wages between $50,000 and $70,000 due to specialized skills in creating precision tools. The job outlook for both roles remains steady, with machinists experiencing moderate growth driven by demand in automotive and aerospace sectors, whereas toolmakers see slower growth but benefit from higher job stability in advanced manufacturing. Salary comparison indicates toolmakers have stronger earning potential influenced by expertise and industry specialization.

Industry Demand and Opportunities

Machinists and toolmakers both play critical roles in manufacturing, but the demand for machinists is currently higher due to their versatility in operating various CNC machines and producing precision parts across multiple industries. Toolmakers, who specialize in creating and maintaining tooling equipment, experience more niche demand, often concentrated in sectors like aerospace and automotive manufacturing where precision tooling is essential. Rapid advancements in automation and Industry 4.0 technologies are expanding opportunities for machinists skilled in programming and setting CNC machinery, while toolmakers with expertise in CAD/CAM software remain vital for custom tool design and maintenance.

Choosing the Right Career Path

Machinists specialize in operating machine tools to produce precision metal parts, while toolmakers focus on designing and building custom tools, dies, and molds essential for manufacturing processes. Choosing the right career path depends on an individual's preference for hands-on machinery operation versus intricate tool design and fabrication skills. Understanding the distinct responsibilities, skill requirements, and career growth opportunities in both fields ensures a well-informed decision in the manufacturing industry.

Machinist vs Toolmaker Infographic

jobdiv.com

jobdiv.com