CNC operators are responsible for setting up, running, and monitoring CNC machines to ensure precision in manufacturing processes, while CNC programmers create the detailed instructions and code that guide these machines. Operators focus on the practical aspects of machine handling and troubleshooting, whereas programmers specialize in designing the toolpaths and optimizing machining sequences through software. Both roles require technical expertise, but programmers drive the CNC machine's functionality by translating engineering designs into executable programs.

Table of Comparison

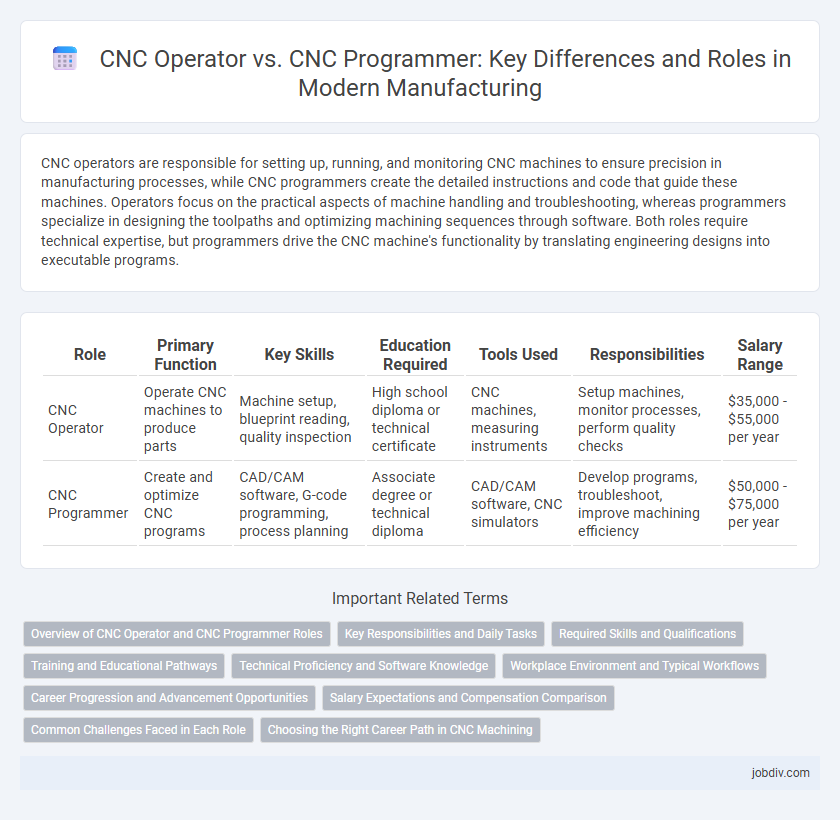

| Role | Primary Function | Key Skills | Education Required | Tools Used | Responsibilities | Salary Range |

|---|---|---|---|---|---|---|

| CNC Operator | Operate CNC machines to produce parts | Machine setup, blueprint reading, quality inspection | High school diploma or technical certificate | CNC machines, measuring instruments | Setup machines, monitor processes, perform quality checks | $35,000 - $55,000 per year |

| CNC Programmer | Create and optimize CNC programs | CAD/CAM software, G-code programming, process planning | Associate degree or technical diploma | CAD/CAM software, CNC simulators | Develop programs, troubleshoot, improve machining efficiency | $50,000 - $75,000 per year |

Overview of CNC Operator and CNC Programmer Roles

CNC Operators are responsible for setting up and controlling computer numerical control machines to produce precision parts according to engineering specifications. CNC Programmers develop and input the code that guides CNC machines, translating design blueprints into detailed instructions for automated manufacturing. Both roles require technical expertise in machining processes, but programmers focus on code creation while operators manage machine operation and quality control.

Key Responsibilities and Daily Tasks

CNC Operators monitor and maintain CNC machines, load materials, and ensure the machine runs efficiently by performing routine inspections and quality checks on produced parts. CNC Programmers develop and optimize the G-code instructions based on technical drawings, create tool paths, and adjust programs to improve manufacturing precision and efficiency. Operators focus on machine operation and troubleshooting, while programmers handle code creation and process planning to enhance production workflows.

Required Skills and Qualifications

CNC Operators require proficiency in machine setup, tool changes, and basic blueprint reading, with vocational training or on-the-job experience being essential for effective machine operation. CNC Programmers must possess advanced skills in G-code programming, CAD/CAM software, and process optimization, typically holding technical degrees or certifications in manufacturing technology. Both roles demand strong problem-solving abilities, attention to detail, and familiarity with safety protocols to ensure precise and efficient production.

Training and Educational Pathways

CNC Operators typically undergo vocational training or technical certificates focused on machine operation, blueprint reading, and basic equipment maintenance, emphasizing hands-on skills for executing pre-programmed tasks. CNC Programmers require more advanced education, often earning associate or bachelor's degrees in manufacturing engineering or computer-aided design (CAD), with specialized training in G-code, CAD/CAM software, and process optimization to develop complex machining programs. Both roles benefit from apprenticeships and continuous industry-specific certifications, but programmers demand stronger expertise in software and programming concepts while operators focus on practical machine handling.

Technical Proficiency and Software Knowledge

A CNC Operator excels in machine setup and real-time control of CNC equipment, requiring hands-on technical proficiency in interpreting blueprints and managing tool changes. CNC Programmers demand advanced software knowledge, including expertise in CAD/CAM systems and G-code programming to design precise machining instructions. Both roles necessitate a strong understanding of CNC machinery, though programmers prioritize programming accuracy while operators emphasize practical execution.

Workplace Environment and Typical Workflows

CNC Operators typically work on the shop floor, directly handling machine setup, tool changes, and monitoring production runs to ensure quality standards, often in noisy, temperature-variable environments. CNC Programmers usually operate in office or controlled workshop settings where they develop and optimize G-code programs using CAD/CAM software, focusing on precision and efficiency in machining processes. Workflow for CNC Operators centers on machine operation and maintenance, while CNC Programmers emphasize code validation, simulation, and process planning before production begins.

Career Progression and Advancement Opportunities

CNC operators typically begin their careers managing machine setup and basic operations, gaining hands-on experience with equipment and tooling. CNC programmers advance by developing complex machining instructions and optimizing processes using CAD/CAM software, leading to higher-paying roles such as manufacturing engineers or production supervisors. Career progression from operator to programmer involves acquiring technical skills and certification, opening pathways to leadership positions and specialized manufacturing roles.

Salary Expectations and Compensation Comparison

CNC Operators typically earn between $35,000 and $50,000 annually, reflecting their role in machine setup and routine operation. CNC Programmers command higher salaries, often ranging from $50,000 to $75,000, due to their expertise in creating detailed machining instructions and optimizing production efficiency. Compensation for CNC Programmers generally includes performance bonuses and advanced skill incentives, highlighting the premium on programming proficiency in manufacturing settings.

Common Challenges Faced in Each Role

CNC Operators often face challenges related to machine setup accuracy, tool wear monitoring, and maintaining consistent quality during production runs. CNC Programmers encounter difficulties in creating error-free G-code, adapting programs to different materials, and optimizing tool paths for efficiency. Both roles require continuous collaboration to troubleshoot discrepancies between program instructions and machine performance.

Choosing the Right Career Path in CNC Machining

CNC operators focus on setting up, running, and maintaining CNC machines to produce parts according to specifications, requiring hands-on technical skills and attention to detail in manufacturing environments. CNC programmers develop and optimize machine code using CAD/CAM software to create precise toolpaths, demanding strong analytical skills and proficiency in programming languages such as G-code. Choosing between these career paths depends on an individual's preference for direct machine operation versus programming, as well as their technical aptitude and long-term goals in the CNC machining industry.

CNC Operator vs CNC Programmer Infographic

jobdiv.com

jobdiv.com