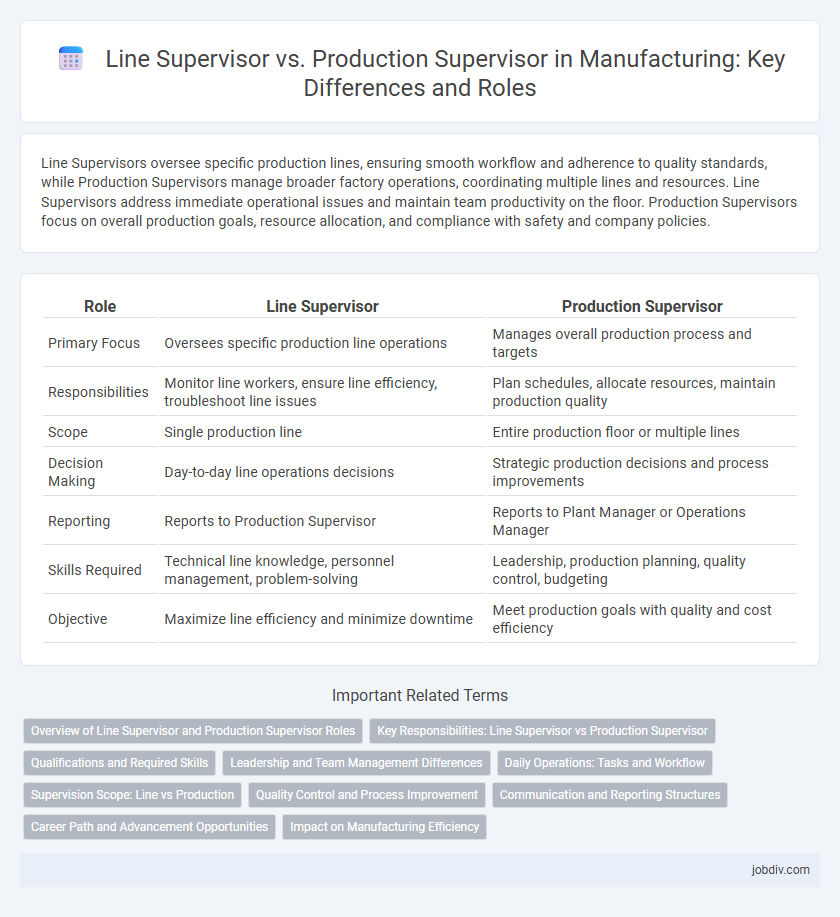

Line Supervisors oversee specific production lines, ensuring smooth workflow and adherence to quality standards, while Production Supervisors manage broader factory operations, coordinating multiple lines and resources. Line Supervisors address immediate operational issues and maintain team productivity on the floor. Production Supervisors focus on overall production goals, resource allocation, and compliance with safety and company policies.

Table of Comparison

| Role | Line Supervisor | Production Supervisor |

|---|---|---|

| Primary Focus | Oversees specific production line operations | Manages overall production process and targets |

| Responsibilities | Monitor line workers, ensure line efficiency, troubleshoot line issues | Plan schedules, allocate resources, maintain production quality |

| Scope | Single production line | Entire production floor or multiple lines |

| Decision Making | Day-to-day line operations decisions | Strategic production decisions and process improvements |

| Reporting | Reports to Production Supervisor | Reports to Plant Manager or Operations Manager |

| Skills Required | Technical line knowledge, personnel management, problem-solving | Leadership, production planning, quality control, budgeting |

| Objective | Maximize line efficiency and minimize downtime | Meet production goals with quality and cost efficiency |

Overview of Line Supervisor and Production Supervisor Roles

Line Supervisors oversee specific production lines, ensuring each stage meets quality standards and efficiency targets, while Production Supervisors manage overall manufacturing workflows, coordinating multiple lines and resources to achieve production goals. Line Supervisors handle real-time troubleshooting and direct worker guidance, whereas Production Supervisors focus on strategic planning, scheduling, and cross-department collaboration. Both roles require leadership skills, but Production Supervisors typically assume broader responsibilities involving budget management and continuous improvement initiatives.

Key Responsibilities: Line Supervisor vs Production Supervisor

Line Supervisors oversee specific production lines, ensuring machines operate efficiently and workers follow safety protocols to meet daily production targets. Production Supervisors manage entire production shifts or departments, coordinating schedules, quality control, and resource allocation to optimize overall manufacturing output. Both roles require strong leadership and communication skills but differ in scope, with Line Supervisors focusing on detailed line-level operations and Production Supervisors handling broader process management.

Qualifications and Required Skills

Line Supervisors require strong technical expertise in machinery operation and quality control, typically supported by a technical diploma or associate degree. Production Supervisors need advanced leadership skills, process optimization knowledge, and often hold a bachelor's degree in industrial engineering or manufacturing management. Both roles demand proficiency in team coordination, safety compliance, and real-time problem-solving to maximize production efficiency.

Leadership and Team Management Differences

Line Supervisors focus on overseeing specific production lines, ensuring workflow efficiency and quality control by directly managing frontline workers and addressing immediate operational issues. Production Supervisors hold broader responsibilities, coordinating multiple line activities, managing cross-functional teams, and aligning production goals with overall manufacturing targets. Leadership in Line Supervisors emphasizes hands-on problem-solving and day-to-day team guidance, while Production Supervisors drive strategic planning and performance optimization across departments.

Daily Operations: Tasks and Workflow

Line Supervisors oversee specific production lines, ensuring machinery runs smoothly and workers follow safety protocols to maintain consistent output. Production Supervisors manage broader operational workflows, coordinating between multiple lines, scheduling shifts, and addressing bottlenecks to optimize overall factory efficiency. Both roles require real-time problem-solving and team leadership to meet daily production targets and quality standards.

Supervision Scope: Line vs Production

Line Supervisors oversee specific assembly or production lines, ensuring operational efficiency, quality control, and safety on their designated line. Production Supervisors manage multiple lines or entire shifts, coordinating workflow, resource allocation, and overall production targets across the manufacturing floor. The supervision scope for Line Supervisors is more focused and task-specific, while Production Supervisors handle broader operational oversight and strategic management of production activities.

Quality Control and Process Improvement

Line Supervisors oversee daily operations on the production floor, ensuring adherence to quality control standards and promptly addressing deviations to maintain product consistency. Production Supervisors manage broader process improvement initiatives, analyzing workflow efficiency and implementing strategic changes to optimize manufacturing output and reduce defects. Both roles collaborate to uphold stringent quality assurance protocols while driving continuous improvement in production processes.

Communication and Reporting Structures

Line Supervisors oversee day-to-day operations on the production floor, ensuring direct communication with machine operators and workers to address immediate issues effectively. Production Supervisors manage broader reporting structures, coordinating between line supervisors and upper management to align production goals with company objectives. Clear communication channels between these roles enhance operational efficiency and ensure accurate reporting for performance monitoring.

Career Path and Advancement Opportunities

Line Supervisors typically manage specific workstations or segments within the production process, offering foundational leadership experience essential for career growth. Production Supervisors oversee entire production lines or shifts, providing broader operational responsibilities that pave the way for higher management roles such as Plant Manager or Operations Director. Advancement opportunities accelerate with demonstrated proficiency in process optimization, team leadership, and cross-functional coordination within these supervisory positions.

Impact on Manufacturing Efficiency

The Line Supervisor directly oversees the workers and machinery on the production floor, ensuring real-time adherence to quality standards and minimizing downtime, which significantly enhances manufacturing efficiency. Production Supervisors manage broader operational aspects, including scheduling, resource allocation, and coordination between departments, optimizing overall workflow and capacity utilization. Effective collaboration between both roles drives continuous improvement, reduces bottlenecks, and boosts productivity in manufacturing environments.

Line Supervisor vs Production Supervisor Infographic

jobdiv.com

jobdiv.com