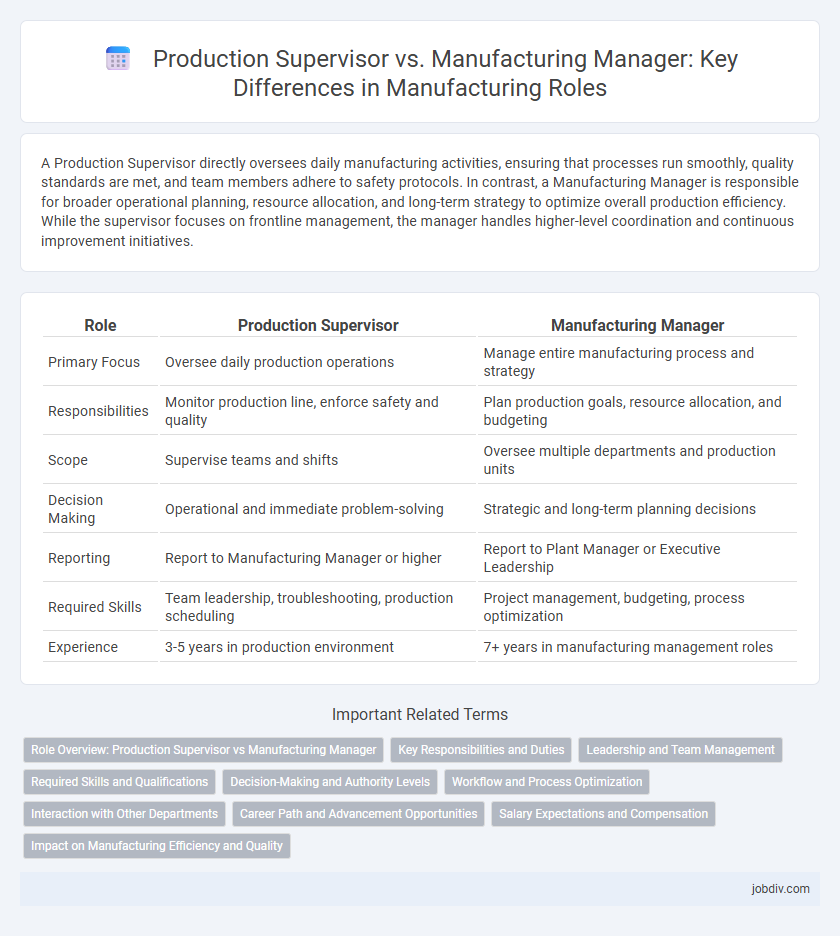

A Production Supervisor directly oversees daily manufacturing activities, ensuring that processes run smoothly, quality standards are met, and team members adhere to safety protocols. In contrast, a Manufacturing Manager is responsible for broader operational planning, resource allocation, and long-term strategy to optimize overall production efficiency. While the supervisor focuses on frontline management, the manager handles higher-level coordination and continuous improvement initiatives.

Table of Comparison

| Role | Production Supervisor | Manufacturing Manager |

|---|---|---|

| Primary Focus | Oversee daily production operations | Manage entire manufacturing process and strategy |

| Responsibilities | Monitor production line, enforce safety and quality | Plan production goals, resource allocation, and budgeting |

| Scope | Supervise teams and shifts | Oversee multiple departments and production units |

| Decision Making | Operational and immediate problem-solving | Strategic and long-term planning decisions |

| Reporting | Report to Manufacturing Manager or higher | Report to Plant Manager or Executive Leadership |

| Required Skills | Team leadership, troubleshooting, production scheduling | Project management, budgeting, process optimization |

| Experience | 3-5 years in production environment | 7+ years in manufacturing management roles |

Role Overview: Production Supervisor vs Manufacturing Manager

A Production Supervisor oversees daily operations on the manufacturing floor, ensuring workflow efficiency, quality control, and team coordination among production staff. The Manufacturing Manager holds a broader responsibility, managing overall production processes, resource allocation, and strategic planning to meet organizational goals. Both roles are critical for seamless manufacturing operations, with supervisors focusing on hands-on team leadership and managers driving higher-level process optimization.

Key Responsibilities and Duties

A Production Supervisor oversees day-to-day operations on the manufacturing floor, ensuring that production targets, quality standards, and safety protocols are met by directly managing line workers and coordinating workflow. In contrast, a Manufacturing Manager holds broader responsibilities that include strategic planning, resource allocation, and continuous improvement initiatives to optimize overall production efficiency and meet organizational goals. While both roles focus on operational excellence, the Production Supervisor emphasizes immediate task coordination, whereas the Manufacturing Manager drives long-term process enhancements and cross-department collaboration.

Leadership and Team Management

Production Supervisors directly oversee daily operations and manage frontline workers, ensuring tasks are completed efficiently while maintaining quality standards. Manufacturing Managers take a broader leadership role, coordinating multiple teams, optimizing workflows, and implementing strategic initiatives to drive overall production performance. Effective team management at both levels requires strong communication skills and the ability to motivate employees in a fast-paced manufacturing environment.

Required Skills and Qualifications

Production Supervisors require strong leadership skills, hands-on knowledge of assembly line processes, and proficiency in quality control and safety standards compliance. Manufacturing Managers need advanced expertise in operations management, strategic planning, budget oversight, and team development, often supported by a degree in engineering or industrial management. Both roles demand excellent communication skills and the ability to analyze production data for continuous improvement.

Decision-Making and Authority Levels

Production Supervisors primarily oversee day-to-day operations on the manufacturing floor, making immediate decisions related to workflow, quality control, and team coordination. Manufacturing Managers hold higher authority, responsible for strategic planning, resource allocation, and overall production efficiency across multiple departments. The distinction in decision-making reflects a hierarchy where supervisors implement policies set by managers, who possess broader responsibility and control over operational outcomes.

Workflow and Process Optimization

Production Supervisors oversee day-to-day manufacturing operations, focusing on worker productivity and immediate workflow issues to ensure smooth production line performance. Manufacturing Managers implement broader process optimization strategies, analyzing production data and integrating technologies to enhance overall operational efficiency and reduce waste. Workflow improvements led by Production Supervisors address short-term bottlenecks, while Manufacturing Managers drive long-term process redesign and continuous improvement initiatives.

Interaction with Other Departments

A Production Supervisor coordinates directly with floor workers and quality control teams to ensure daily manufacturing targets are met, emphasizing operational efficiency. In contrast, a Manufacturing Manager interacts broadly across departments such as procurement, engineering, and logistics to align production schedules with overall business goals. Effective cross-functional communication enables both roles to optimize workflow, reduce bottlenecks, and maintain consistent product quality.

Career Path and Advancement Opportunities

Production Supervisors typically oversee day-to-day operations on the manufacturing floor, gaining hands-on experience with workforce management and process optimization. Transitioning to a Manufacturing Manager role involves expanding responsibilities to strategic planning, budgeting, and cross-departmental coordination, often requiring advanced skills in project management and leadership. Career advancement from Production Supervisor to Manufacturing Manager offers increased influence over production strategy and greater opportunities for executive-level positions within manufacturing organizations.

Salary Expectations and Compensation

Production Supervisors typically earn between $50,000 and $70,000 annually, reflecting their role in overseeing daily operations and workforce management on the production floor. Manufacturing Managers command higher salaries, ranging from $80,000 to $120,000 or more, due to their broader responsibilities in strategic planning, process optimization, and budget oversight. Compensation packages for Manufacturing Managers often include bonuses and stock options, highlighting the higher level of accountability and decision-making authority in the manufacturing hierarchy.

Impact on Manufacturing Efficiency and Quality

A Production Supervisor directly oversees daily operations on the manufacturing floor, ensuring that workers adhere to quality standards and production schedules, which leads to immediate improvements in efficiency and product consistency. In contrast, a Manufacturing Manager takes a broader strategic role by optimizing processes, implementing advanced technologies, and managing cross-departmental coordination to enhance long-term manufacturing efficiency and product quality. Both roles are crucial, but the Production Supervisor drives operational discipline while the Manufacturing Manager focuses on systemic improvements and resource allocation.

Production Supervisor vs Manufacturing Manager Infographic

jobdiv.com

jobdiv.com