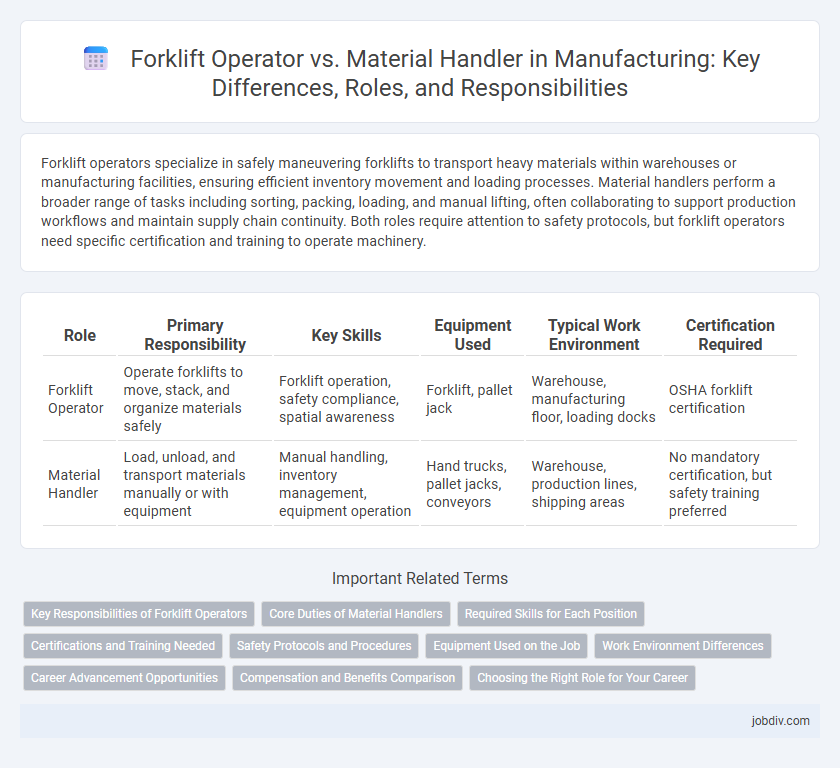

Forklift operators specialize in safely maneuvering forklifts to transport heavy materials within warehouses or manufacturing facilities, ensuring efficient inventory movement and loading processes. Material handlers perform a broader range of tasks including sorting, packing, loading, and manual lifting, often collaborating to support production workflows and maintain supply chain continuity. Both roles require attention to safety protocols, but forklift operators need specific certification and training to operate machinery.

Table of Comparison

| Role | Primary Responsibility | Key Skills | Equipment Used | Typical Work Environment | Certification Required |

|---|---|---|---|---|---|

| Forklift Operator | Operate forklifts to move, stack, and organize materials safely | Forklift operation, safety compliance, spatial awareness | Forklift, pallet jack | Warehouse, manufacturing floor, loading docks | OSHA forklift certification |

| Material Handler | Load, unload, and transport materials manually or with equipment | Manual handling, inventory management, equipment operation | Hand trucks, pallet jacks, conveyors | Warehouse, production lines, shipping areas | No mandatory certification, but safety training preferred |

Key Responsibilities of Forklift Operators

Forklift operators primarily handle the safe and efficient movement of heavy materials using powered industrial trucks within a manufacturing facility. They are responsible for loading, unloading, stacking, and transporting products, ensuring precise placement to maintain workflow continuity and warehouse organization. Regular inspection, maintenance, and adherence to safety protocols are critical tasks to prevent equipment failure and workplace accidents.

Core Duties of Material Handlers

Material handlers in manufacturing are responsible for loading, unloading, and transporting raw materials and finished goods within the facility, ensuring smooth workflow and inventory accuracy. They operate equipment such as pallet jacks, conveyors, and forklifts to move items efficiently between production areas, storage, and shipping docks. Material handlers also perform quality inspections, maintain material storage systems, and assist with inventory management to support continuous production processes.

Required Skills for Each Position

Forklift operators require specialized skills such as proficiency in operating forklifts safely, understanding load capacities, and precise maneuvering in warehouse environments. Material handlers must possess strong organizational abilities, knowledge of inventory management systems, and physical stamina for lifting and moving various materials. Both positions demand attention to safety regulations, communication skills, and the ability to work efficiently within fast-paced manufacturing settings.

Certifications and Training Needed

Forklift operators must obtain OSHA certification, which requires hands-on training and a written exam to ensure safe machinery operation in manufacturing environments. Material handlers typically need general workplace safety training and may require certifications such as OSHA's Hazard Communication or first aid, depending on the job scope. Both roles benefit from ongoing training programs to comply with industry standards and promote workplace safety.

Safety Protocols and Procedures

Forklift operators must strictly adhere to safety protocols such as wearing PPE, conducting pre-operation equipment checks, and following designated traffic patterns to prevent accidents in manufacturing environments. Material handlers prioritize safe manual handling techniques, including proper lifting methods and ergonomic practices, to reduce the risk of musculoskeletal injuries. Both roles require ongoing safety training and compliance with OSHA standards to maintain workplace safety and efficiency.

Equipment Used on the Job

Forklift operators primarily use powered industrial trucks such as forklifts, pallet jacks, and reach trucks to move heavy pallets and materials efficiently across manufacturing floors. Material handlers operate a broader range of equipment, including conveyors, cranes, hoists, and sometimes forklifts, to manage the flow of raw materials and finished goods. Specialized tools like barcode scanners and inventory management software are integral to material handlers for tracking and organizing shipments accurately.

Work Environment Differences

Forklift operators typically work in controlled warehouse settings with defined pathways, handling heavy pallets and goods efficiently using forklifts, which demands specialized certification and high safety standards. Material handlers operate in more varied environments including loading docks, assembly lines, and outdoor areas, requiring flexibility to manually lift, move, or organize materials without always using mechanized equipment. The work environment for forklift operators is usually more structured and indoors, while material handlers adapt to a broader range of indoor and outdoor conditions, influencing the physical demands and safety protocols of each role.

Career Advancement Opportunities

Forklift operators often have specialized skills in operating heavy machinery, which can lead to advanced certifications and supervisory roles within warehouse management. Material handlers typically gain diverse experience in inventory control and logistics, providing pathways to supply chain coordination and warehouse management positions. Both career paths offer strong advancement opportunities, with career growth depending on skill development and additional training in manufacturing operations.

Compensation and Benefits Comparison

Forklift operators in manufacturing typically earn higher wages than material handlers due to specialized skills in operating heavy machinery and certifications such as OSHA Forklift Operator Safety. Benefits for forklift operators often include hazard pay, comprehensive health packages, and opportunities for overtime, reflecting the job's higher risk and responsibility levels. Material handlers receive competitive base salaries with benefits focused on health insurance and paid time off, but they generally have fewer incentives related to skill certification and equipment operation.

Choosing the Right Role for Your Career

Forklift operators specialize in maneuvering forklifts to transport heavy materials efficiently within warehouses and manufacturing facilities, making them ideal for those seeking specialized equipment operation roles. Material handlers perform a broader range of tasks including loading, unloading, sorting, and moving materials manually or with various equipment, offering versatility and a wider skill set. Selecting the right role depends on career goals: choose forklift operator for focused machine operation expertise or material handler for diversified logistics and supply chain experience.

Forklift Operator vs Material Handler Infographic

jobdiv.com

jobdiv.com