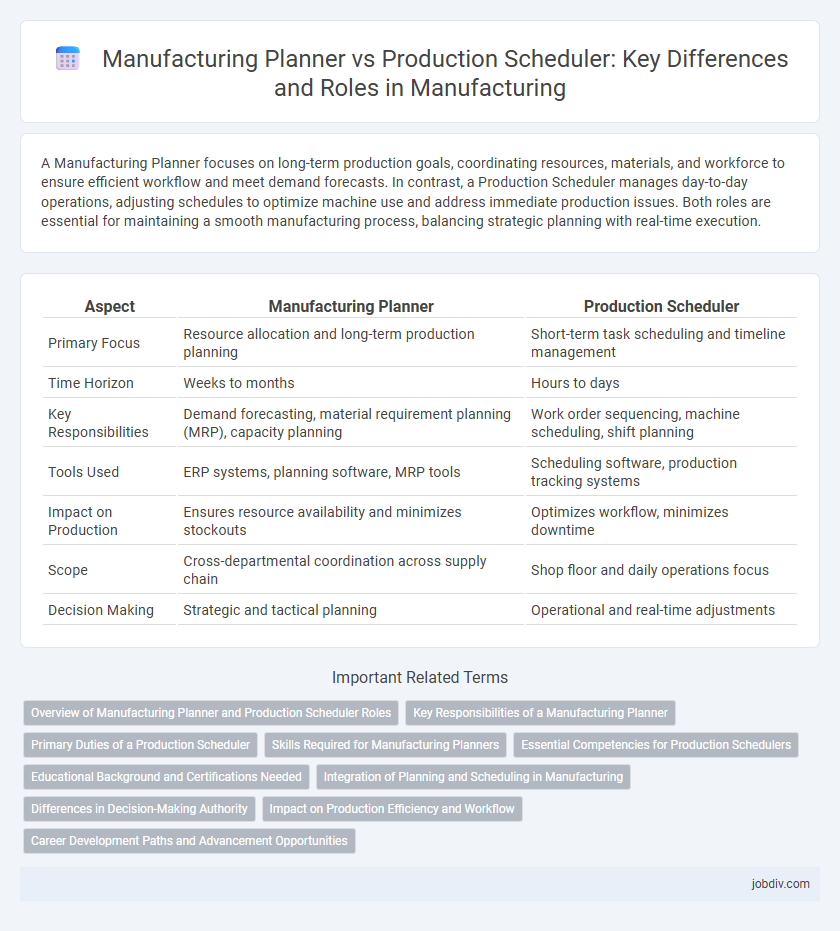

A Manufacturing Planner focuses on long-term production goals, coordinating resources, materials, and workforce to ensure efficient workflow and meet demand forecasts. In contrast, a Production Scheduler manages day-to-day operations, adjusting schedules to optimize machine use and address immediate production issues. Both roles are essential for maintaining a smooth manufacturing process, balancing strategic planning with real-time execution.

Table of Comparison

| Aspect | Manufacturing Planner | Production Scheduler |

|---|---|---|

| Primary Focus | Resource allocation and long-term production planning | Short-term task scheduling and timeline management |

| Time Horizon | Weeks to months | Hours to days |

| Key Responsibilities | Demand forecasting, material requirement planning (MRP), capacity planning | Work order sequencing, machine scheduling, shift planning |

| Tools Used | ERP systems, planning software, MRP tools | Scheduling software, production tracking systems |

| Impact on Production | Ensures resource availability and minimizes stockouts | Optimizes workflow, minimizes downtime |

| Scope | Cross-departmental coordination across supply chain | Shop floor and daily operations focus |

| Decision Making | Strategic and tactical planning | Operational and real-time adjustments |

Overview of Manufacturing Planner and Production Scheduler Roles

A Manufacturing Planner focuses on creating detailed production plans by forecasting demand, managing inventory levels, and coordinating material procurement to ensure smooth manufacturing processes. A Production Scheduler organizes and sequences production activities on the shop floor, allocating resources and timing tasks to optimize workflow and meet delivery deadlines. Both roles collaborate closely to align production capabilities with business goals, balancing efficiency and flexibility in manufacturing operations.

Key Responsibilities of a Manufacturing Planner

A Manufacturing Planner is responsible for developing detailed production schedules, coordinating raw material procurement, and ensuring inventory levels align with production requirements to optimize manufacturing efficiency. This role involves analyzing demand forecasts, balancing workload across workstations, and liaising with suppliers and production teams to prevent bottlenecks and delays. By maintaining accurate production data and adjusting plans proactively, Manufacturing Planners support seamless operations and cost-effective resource management.

Primary Duties of a Production Scheduler

A Production Scheduler develops detailed production timelines, coordinates job sequences, and allocates resources to ensure efficient workflow and timely order completion. They monitor production progress, adjust schedules based on capacity, and mitigate bottlenecks to maintain optimal equipment utilization. Accurate production scheduling enhances inventory control, reduces lead times, and supports on-time delivery in manufacturing operations.

Skills Required for Manufacturing Planners

Manufacturing planners require strong analytical skills, proficiency in production planning software, and a deep understanding of supply chain management to optimize resource allocation and inventory control. Expertise in demand forecasting, capacity planning, and coordination across multiple departments enables efficient workflow and timely order fulfillment. Effective communication and problem-solving abilities are essential for adapting plans to dynamic manufacturing environments and aligning production goals with business objectives.

Essential Competencies for Production Schedulers

Production schedulers require strong analytical skills, adeptness in real-time data interpretation, and proficiency in advanced scheduling software to optimize workflow and minimize downtime. They must excel in resource allocation, time management, and effective communication to coordinate between departments and maintain production timelines. Understanding inventory control, capacity planning, and problem-solving under pressure are crucial for ensuring seamless manufacturing operations.

Educational Background and Certifications Needed

Manufacturing planners typically require a bachelor's degree in industrial engineering, manufacturing engineering, or supply chain management, emphasizing knowledge in production planning and resource allocation. Production schedulers often hold degrees in operations management or logistics and benefit from certifications such as APICS Certified in Production and Inventory Management (CPIM). Both roles value expertise in ERP systems, but planners prioritize strategic planning education while schedulers focus on detailed scheduling and execution certifications.

Integration of Planning and Scheduling in Manufacturing

Manufacturing planners develop comprehensive production strategies that allocate resources and set timelines to meet demand forecasts, while production schedulers translate these plans into detailed, day-to-day schedules optimizing machine and labor usage. Integration of planning and scheduling ensures seamless communication between strategic allocation and operational execution, enhancing production efficiency and reducing lead times. Advanced manufacturing systems leverage integrated software platforms to synchronize planning and scheduling, enabling real-time adjustments and improved responsiveness to supply chain fluctuations.

Differences in Decision-Making Authority

Manufacturing planners typically hold broader decision-making authority by forecasting demand, allocating resources, and establishing production strategies to meet long-term objectives. Production schedulers focus on short-term operational control, sequencing tasks, assigning work shifts, and adjusting schedules based on real-time shop floor conditions. The distinction lies in planners shaping high-level plans, while schedulers execute detailed timelines critical for day-to-day manufacturing efficiency.

Impact on Production Efficiency and Workflow

The Manufacturing Planner strategically allocates resources and develops long-term production plans to optimize overall capacity and minimize bottlenecks, directly enhancing production efficiency. In contrast, the Production Scheduler focuses on short-term task sequencing and real-time adjustments, ensuring smooth workflow and timely order completion. Together, their coordinated roles reduce downtime and improve throughput, driving continuous operational excellence in manufacturing environments.

Career Development Paths and Advancement Opportunities

Manufacturing Planners typically focus on long-term production strategies, demand forecasting, and resource allocation, positioning them for advancement into supply chain management or operations leadership roles. Production Schedulers concentrate on short-term scheduling, workflow optimization, and real-time problem solving, paving the way for career growth into production management or process improvement specialist positions. Both roles offer critical pathways in manufacturing career development, with planners leaning towards strategic oversight and schedulers excelling in tactical execution.

Manufacturing Planner vs Production Scheduler Infographic

jobdiv.com

jobdiv.com