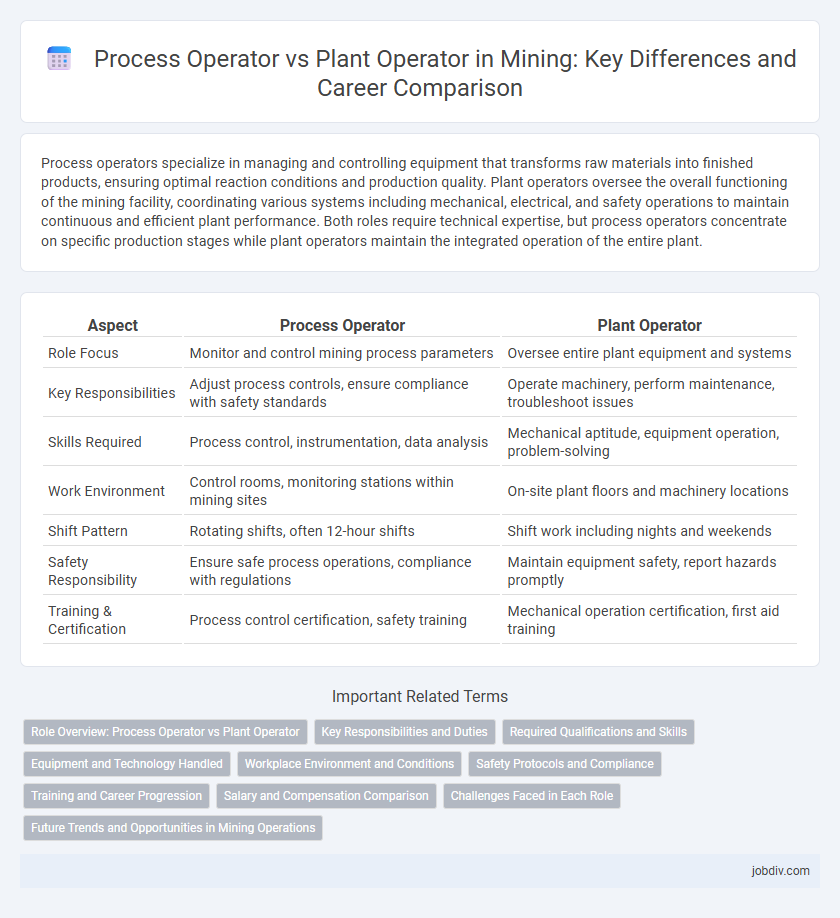

Process operators specialize in managing and controlling equipment that transforms raw materials into finished products, ensuring optimal reaction conditions and production quality. Plant operators oversee the overall functioning of the mining facility, coordinating various systems including mechanical, electrical, and safety operations to maintain continuous and efficient plant performance. Both roles require technical expertise, but process operators concentrate on specific production stages while plant operators maintain the integrated operation of the entire plant.

Table of Comparison

| Aspect | Process Operator | Plant Operator |

|---|---|---|

| Role Focus | Monitor and control mining process parameters | Oversee entire plant equipment and systems |

| Key Responsibilities | Adjust process controls, ensure compliance with safety standards | Operate machinery, perform maintenance, troubleshoot issues |

| Skills Required | Process control, instrumentation, data analysis | Mechanical aptitude, equipment operation, problem-solving |

| Work Environment | Control rooms, monitoring stations within mining sites | On-site plant floors and machinery locations |

| Shift Pattern | Rotating shifts, often 12-hour shifts | Shift work including nights and weekends |

| Safety Responsibility | Ensure safe process operations, compliance with regulations | Maintain equipment safety, report hazards promptly |

| Training & Certification | Process control certification, safety training | Mechanical operation certification, first aid training |

Role Overview: Process Operator vs Plant Operator

Process Operators control and monitor the technical processes involved in mining operations, ensuring efficiency and safety in material extraction and processing systems. Plant Operators manage the overall functionality of mining plant equipment, overseeing maintenance, operation schedules, and adherence to production targets. Both roles require detailed knowledge of mining machinery, safety protocols, and operational workflows to optimize resource recovery and minimize downtime.

Key Responsibilities and Duties

Process Operators in mining manage the control and optimization of equipment and systems to ensure efficient ore processing and recovery. Plant Operators oversee the daily operations of processing plants, including monitoring machinery performance, maintenance coordination, and ensuring compliance with safety and environmental standards. Both roles are critical for maintaining production quality and meeting operational targets in mining facilities.

Required Qualifications and Skills

Process Operators typically require a technical diploma in process technology or engineering, with skills in monitoring production systems, interpreting process data, and troubleshooting equipment malfunctions. Plant Operators need certifications in industrial machinery operation and expertise in maintaining mechanical systems, safety protocols, and coordinating plant activities. Both roles demand strong analytical skills, attention to detail, and knowledge of health and safety regulations in mining environments.

Equipment and Technology Handled

Process Operators in mining specialize in managing chemical and physical equipment such as reactors, mixers, and filtration systems to ensure the efficient transformation of raw minerals. Plant Operators oversee heavy machinery and large-scale equipment including crushers, conveyors, and flotation cells responsible for material handling and processing. Both roles require proficiency with control systems like SCADA and DCS to monitor operations and maintain optimal performance.

Workplace Environment and Conditions

Process Operators in mining typically work in control rooms monitoring and adjusting equipment, facing less exposure to harsh physical elements but requiring vigilance for system anomalies. Plant Operators operate on-site amidst crushers, conveyors, and heavy machinery, encountering high noise levels, dust, and varying temperatures that demand rigorous adherence to safety protocols. Both roles require strong situational awareness and compliance with occupational health and safety standards to manage the demanding workplace environments effectively.

Safety Protocols and Compliance

Process Operators and Plant Operators in mining both adhere strictly to safety protocols and compliance standards, ensuring operational safety and environmental protection. Process Operators focus on monitoring and controlling chemical and mechanical processes, requiring adherence to hazard identification and risk assessment procedures specific to processing plants. Plant Operators manage overall plant equipment and machinery, emphasizing compliance with operational safety regulations and emergency response plans to prevent accidents and maintain regulatory standards.

Training and Career Progression

Process Operators receive specialized training in equipment control, chemical processing, and safety protocols specific to mineral extraction and processing plants. Plant Operators undergo comprehensive programs covering broader operational areas including maintenance, system monitoring, and team leadership within the entire mining facility. Career progression for Process Operators often leads to technical specialist roles, while Plant Operators may advance to supervisory or managerial positions overseeing multiple plant functions.

Salary and Compensation Comparison

Process Operators in mining typically earn a median salary ranging from $55,000 to $75,000 annually, influenced by experience and site location. Plant Operators often command slightly higher compensation, averaging between $60,000 and $80,000, reflecting their responsibility for overseeing entire processing plants. Benefits packages for both roles usually include performance bonuses, health insurance, and retirement plans, with Plant Operators generally receiving more comprehensive compensation due to their broader operational duties.

Challenges Faced in Each Role

Process operators encounter challenges related to monitoring complex chemical reactions and maintaining precise control over process parameters to ensure product quality and safety. Plant operators face difficulties managing large-scale equipment maintenance, coordinating multiple production stages, and responding swiftly to unplanned shutdowns to minimize downtime. Both roles require strong problem-solving skills, but process operators deal more with system optimization while plant operators handle operational logistics and equipment reliability.

Future Trends and Opportunities in Mining Operations

Process Operators and Plant Operators in mining are increasingly integrating automation and advanced data analytics to enhance operational efficiency and safety. Future trends emphasize the adoption of AI-driven monitoring systems and remote-control technologies, creating opportunities for upskilling in digital and technical competencies. These roles will evolve towards greater involvement in predictive maintenance and real-time process optimization, driving sustainable mining practices.

Process Operator vs Plant Operator Infographic

jobdiv.com

jobdiv.com